The most common misconception of 3D printed jewelry is that it is printed with plastic. This is not the truth. So what are the best and most popular materials for jewelry designers? The answer is the same as traditional handmade jewelry: Gold, silver, brass, and bronze.

Gold

Gold has a beautiful gloss. There are three different available finishes for gold: yellow, white or red. These colors are achieved by adding different metal to gold.

Silver

We use a powerful mechanical polishing technique to round any sharp corners of the high-gloss metal and reach the highest level of smoothness and gloss. The jewelry can also be processed by sandblasting. You can choose a variety of levels of surface roughness.

Brass

Another great material for jewelry designers is brass, an alloy made of copper and zinc. It’s cheap but looks great.

The post-process for 3D printed brass jewelry includes polishing, coating or electroplating.

The skull is printed in brass and coated with natural PU paints.

The fish is printed in brass, polished and then coated with PU paints, lastly electroplated with gold.

The ring is also printed in brass and electroplated with gold.

The same ring but coated with black PU paints. We also offer PU paints in other colors.

Guess how the necklace is made? Yes, also printed in brass, polished and electroplated with gold.

The flying pig is printed in brass and electroplated with chromium.

This flower is electroplated with rhodium.

Bronze

Bronze is an alloy mainly composed of copper, which is a very affordable material. Its color is reddish-yellow. You can apply a PU coating and polish the jewelry to make it more smooth and glossy.

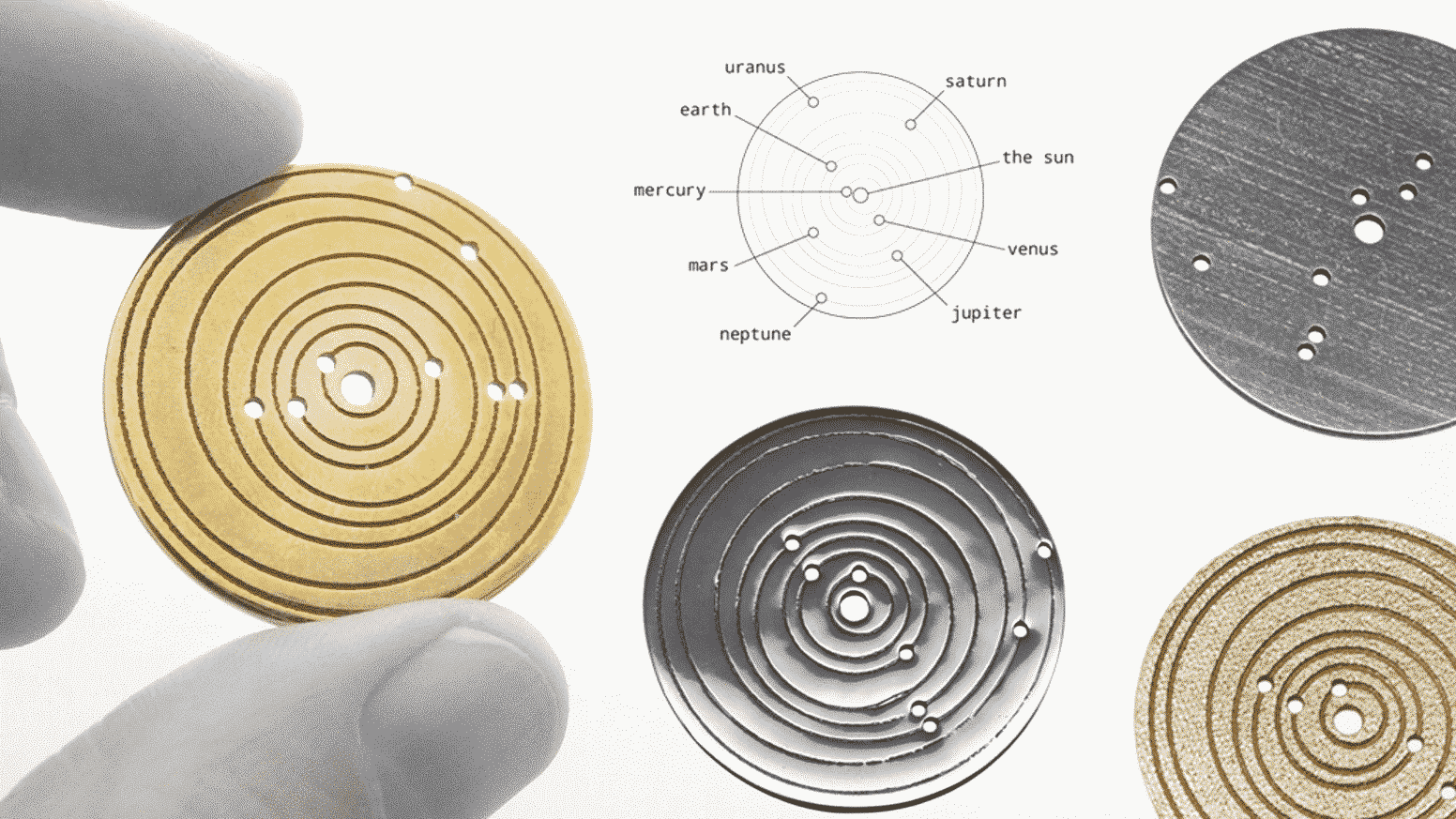

The name of the pendant is SpaceTime Coordinates Memento. It’s designed by Govy and Martin Vézina.

A snake buckle printed in bronze