Many users who own FDM 3D printers are worrying about a problem: is there an effective way to solve the problem of warping during ABS printing? With this question, Facfox will share with you some of the solutions we practically used.

First, what is ABS printing supplies?

ABS (Acrylonitrile Butadiene Styrene) is a common plastic around us. The LEGO bricks we usually see are made of ABS material. Its characteristics include high strength and good heat resistance. Apart from them, ABS also has a fine surface finish. ABS reacts with acetone, so it is much easier to polish an ABS printed object with acetone.

Common problems faced by ABS printing

Although ABS has high strength and good heat resistance, it may encounter a problem during printing, that is, it is difficult to make it stick to the printing bed so that warping is prone to happen when printing. This is a problem people often encounter with ABS, but it is not impossible to be solved.

Why does ABS appear warped?

First, before explaining how to deal with ABS warping, let’s understand why ABS warping occurs.

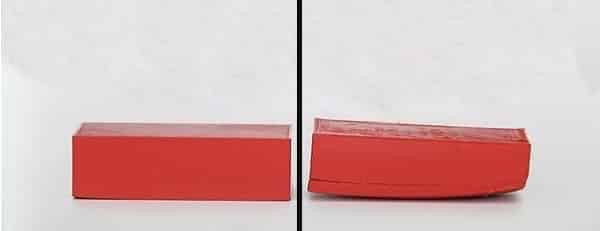

When ABS filament is heated in the extruder, they have a tendency to expand. Once in the molten state, it is deposited layer by layer on the building platform. When the molten filament cools and solidifies, it also shrinks. During printing, the formerly printed layers began to cool down and shrink, causing it to peel off from the build platform, which in turn caused edge warping.

How to solve the ABS printing problems?

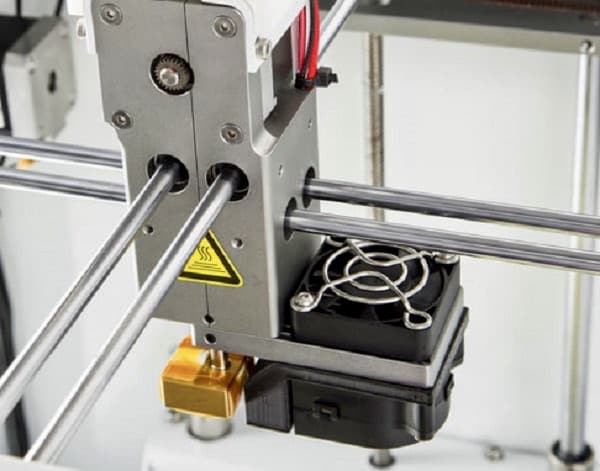

1. Control the heating temperature of the extruder.

ABS melts between 210 – 250 °C. Unless specified by the manufacturer, you should be able to use temperature settings in this range. Our own printers perform quite well under 235 °C.

If you run the extruder too hot, you will notice a lot of stringing between the part walls. If you run too cold, you may find that it doesn’t squeeze enough to print. Of course, the ideal temperature of different machines is still a bit uncertain, which requires you to constantly try different temperatures to sum up the experience.

2. Control the temperature of the heated bed.

Controlling the temperature of the heated bed is the key factor to solve the model warping. It is important to set the correct temperature of the heated bed. The temperature at which a plastic change from a solid to a molten liquid is called the glass transition temperature (Tg). You need to set the heated bed temperature above this point. For ABS, the glass transition temperature is 105 °C, so controlling the bed temperature up to 110 °C is sufficient.

3. Adjust the settings on slicing software.

The slicer has multiple settings that can be adjusted to your needs.

- Edge and Support: The edge and support options in the slicing software settings provide additional surface contact between the part and the base plate. This helps the edge or support to act as a sacrificial additive when the first layer is bonded. In the case of warping, the edges or supports will be affected, while other parts will remain in good condition.

- First layer height: Having a thicker first layer can be beneficial because it increases surface contact and holds the model firmly in place. A standard rule of thumb is to set the first layer to 150% of the normal layer height.

- First layer speed: The print speed of the first layer should be reduced to about 70% of the actual print speed. This is especially useful when your part has sharp corners, which tend to peel off when the hot end moves at higher speeds.

4. Other solutions

- Windshield: The windshield is also a way to solve the warping. With the windshield, it is helpful to maintain a constant temperature environment. This is a single thick wall surrounding the part that prevents air from venting and speeds up the print area.

- Cooling fans: Cooling fans are a great addition to 3D printers because they generate a lot of airflow around the nozzles and quickly cool the plastic. However, this can have a negative effect when printing the first few layers. Before turning on, be sure to turn off the fans on the first 5 to 10 floors.

- Use of adhesives: Another effective way to resist warping is to use adhesives, such as solid glue, textured paper, etc. The adhesive can be directly applied to the hot-bed platform, which helps the printing supplies stick to the platform smoothly.

Of course, different 3D printers in different printing environments may cause ABS to be warped. Consulting professionals will often be more effective, and Facfox is also here to serve.