With over 10 years’ experience of CNC plastic machining, discover how FacFox can help you create custom machined plastic prototypes and components fast. Get a free quote today!

CNC machining has always been traditionally thought of as a method for processing methods. However, the modern industry has been constantly increasing precision demands towards parts of all possible materials. This served as a reason for CNC plastic machining technologies development. It has now occupied a considerable niche in high precision low volume and prototype manufacturing of plastic parts.

Whether you need any plastic prototyping or customized parts, fusing of complex components, or finishing and polishing services with low volume production, we – FacFox can offer advanced CNC prototyping services and high temperature and high-strength plastic machining materials.

For more than 20 years, FacFox has been providing CNC plastic machining and fabricating plastic components for global customers with competitive prices. To learn more about how we can help you to start your new project, contact us today.

The Reason of Plastic Parts Popularity

Why is plastic so popular? Since the invention of industrial-grade polymers, the invasion of plastic into all the branches of modern industry has been unstoppable. And there are a lot of reasons for that. I’ll name only three main reasons. Plastic parts are cheap, lightweight, and durable. Let’s talk about the first point here. By cheap, I mean that the cost of manufacturing them is much lower than that of metal parts.

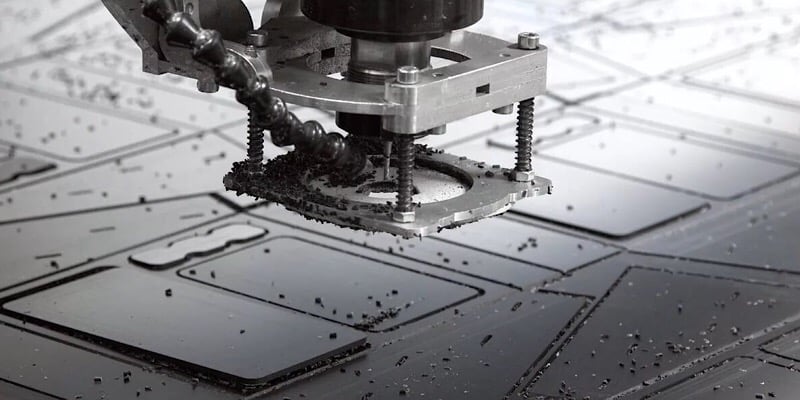

Methods of CNC Plastic Machining

There are a lot of methods to produce high precision plastic parts. Modern industrial-grade plastics are cast, injection-molded, printed, or machined. The first three options are great for manufacturing complex geometry parts with a fine surface finish. However, there is nothing better than machining when you need to achieve a tight tolerance or produce a mirror-like surface finish in almost any kind of part. About 80% of the plastic parts are CNC milled. It is the most widespread method for manufacturing parts without a revolution axis. All the rest are usually turned on a lathe. In some cases, slotting or planning is implemented. Mostly to manufacture inner grooves or rectangular holes. In order to achieve an outstanding surface finish, CNC machined parts are polished or chemically processed.

CNC Plastic Materials

FacFox’s ISO certified CNC equipment can carry out services, including Milling, Turning, Drilling, Sanding, Grinding, Punching, Tooling, Welding. We are capable of creating high-performance plastics of various materials in sheets, round rods, and more.

We can supply most of the CNC plastic materials: ABS, Polypropylene (PP), Polycarbonate (PC), Acrylic (PMMA), Nylon 12(PA12), Nylon 6/66(PA6/66), Derlin (POM), PET, Teflon (PTFE), PEEK, Polyurethane (PU), PVC, PPS, Vespel (PI), Torlon 4203 (PAI), UPE/UHMW, PVDF, ULTEM (PEI), etc.

Tips to Plastic Machining

Machine Tools

First of all, let’s clear, it up. There are no plastic CNC machines. All the machine tools used to cut plastic are actually metal machining tools. Their precision rigidity and power output allow them to process even hardened plastics with ease. I should note that woodworking machine tools won’t do as good of a job though since their rigidity is lower.

Cutting Tools

Choosing the best cutting tools for plastic parts is a complex job. The reason for that is plastic as well as composite materials have a very variable composition. Some plastics are strengthened with hard carbide particles or have some additives that enhance flexibility, thermal resistance, or some other parameter. All of that changes the way a plastic reacts to machining. Even the colorant of the material is important since depending on its type, the tint may change during machining due to extensive heating.

That being said, it becomes apparent that choosing a correct cutting tool geometry for the machined plastic parts is a must. For example, milling tools are similar to aluminum cutters with two flutes, however, the sharp edges have sharper angles. The same thing can be said about drills. Their main angle, which is 120 degrees for metals, becomes only 60 degrees. That way, the chips are smaller and can be removed easier. You can’t use that kind of drill for metals, though. It’ll break in a matter of minutes.

Part Setup

When you set up your CNC plastic blocks, be sure to remember. Plastic isn’t metal. You can easily leave a large mark on the surface if you clamp the blank with too much force. Actually, if you apply too much force, the part will probably just crack. It is advisable to use special pads from a softer material between the fixtures and the part if you want to avoid marks 100%. Another issue is part rigidity. For example, if you are drilling a fairly wide part ( imagine a notebook case). You will need to keep close attention as to how far the drilling place is from the fixtures. The drill will try to pull the part up along its flutes during the process and if the fixtures are too far, the drill will succeed. It will either bend the part or it may actually tear the part from the fixtures.

The Cutting Parameters

Let’s look at the choice for plastic cutting processes by using the example of the CNC Milling Plastic case. The main issue that you have to look out for is excessive friction and plastic deformation of the part instead of cutting. To avoid the second issue, always keep the cutters sharp, and in cases when the material you use isn’t rigid enough, freeze it. Plastic becomes hard and brittle under low temperatures.

In order to prevent the chip from melting to the CNC machined part, you’ll need to keep that tool moving and prevent it from staying in one place for too long. Remove chip as fast as you can. So, the feeds for plastic processing must be big, aggressive even. And with a bigger feed rate, the spindle speeds must be fast as well. The approximate estimation is about 3 times as fast as aluminum feeds and a corresponding cutting speed.

The Role of Plastics in CNC Prototyping

Plastic machining services are tightly related to CNC prototyping art. Polymer materials are perfect for prototype creation and engineering validation. The reason for that is that plastics are actually quite easy to machine. If you don’t have any heating or molding equipment, manufacturing parts from CNC plastic blocks is a good way to get those prototypes easy and fast. You can use the same widespread equipment that is used to process metals, hence, great flexibility. And the cutting speeds and feeds will be much faster, hence, smaller lead-time and an opportunity to test your product sample faster and bring it into the market before your competitors.

CNC Plastic Machining Services

Due to the fact that plastic parts are in great demand for prototyping and customized CNC plastic parts production, a lot of CNC Plastic Machining Services sprang up. They definitely make the manufacturing process faster and easier for all parties. It is especially effective if you don’t have any prior experience with cutting plastic or manufacturing polymer parts overall. Such machining shops gather the best manufacturing specialists, machinists, and design for manufacturability engineers. They will not only be able to procure a professional and aesthetic prototype but will also point out some design issues, improving which can significantly decrease the manufacturing time and cost.