There’s a certain thrill in turning an idea into something you can hold. In today’s fast-paced product development world, that transformation-from concept to prototype-needs to be fast, flexible, and functional. Whether you’re iterating on a new consumer gadget or engineering a precision component for aerospace, rapid prototyping has become a cornerstone of innovation.

Two technologies have emerged as front-runners in the race to prototype faster and smarter: 3D printing and CNC machining. Both offer distinct advantages, and both can feel like the “right” answer-until you realize they couldn’t be more different under the surface.

So, which one should you choose for your next prototype? In this article, we’ll walk you through every key difference, trade-off, and scenario to help you make the right decision based on your project needs.

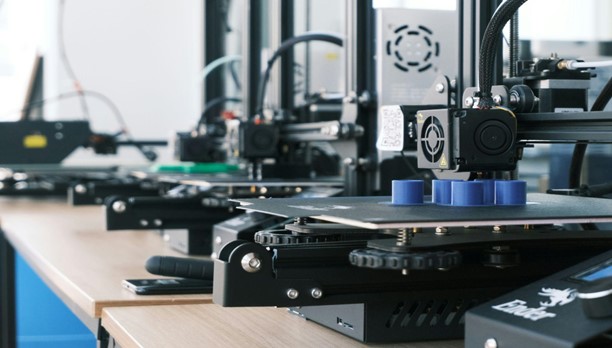

What Is 3D Printing and How Does It Work?

3D printing, also known as additive manufacturing, is the process of creating a physical object from a digital model by depositing material layer by layer. If you’re using a 3D printing service, the process builds objects from the ground up using data from a 3D CAD file, unlike traditional manufacturing methods that carve material away from a block.

The process typically starts with slicing software, which translates a digital 3D model into thin horizontal layers and generates machine instructions. These instructions guide the printer’s nozzle or laser system as it lays down successive material layers.

Common technologies differ based on material type, printing precision, and method of layer fusion.

FDM (Fused Deposition Modeling)

FDM is the most accessible and widely used form of 3D printing. It works by extruding thermoplastic filament through a heated nozzle, layer by layer, until the object is complete.

Pros:

- Affordable machines and materials

- Great for early-stage concept models

- Easy to use and maintain

Cons:

- Lower resolution and surface finish

- Visible layer lines

- Limited mechanical strength compared to other methods

Best used for: quick visual prototypes, simple mechanical parts, and iterative design testing.

SLA (Stereolithography)

SLA (Stereolithography) uses a laser to cure liquid resin into hardened plastic with exceptional detail. If you’re wondering what is Stereolithography (SLA) 3D Printing, it’s ideal when visual quality matters just as much as geometry.

Pros:

- Extremely fine detail and smooth surfaces

- Excellent dimensional accuracy

- Ideal for small, intricate parts

Cons:

- Resins can be brittle

- Requires post-curing and careful handling

- Higher material cost

Best used for: models requiring a premium surface finish or tight tolerances.

SLS (Selective Laser Sintering)

SLS involves a laser sintering powdered material, usually nylon, to create parts without the need for support structures. This makes it well-suited for more complex designs.

Pros:

- High mechanical strength

- No support structures needed

- Excellent for functional prototypes

Cons:

- Expensive equipment

- Rougher surface finish

- Slower post-processing

Best used for: durable, load-bearing parts and small production runs.

What Is CNC Machining and How Does It Work?

CNC machining is a subtractive manufacturing process that begins with a solid block of material and uses computer-controlled cutting tools to remove material until the desired shape is formed.

It typically follows this workflow: a CAD file is converted into G-code using CAM software, which then instructs the machine on how to cut the part with high accuracy. CNC machines operate across multiple axes and come in various types tailored to different geometries and materials.

This method is known for its precision, material versatility, and finish quality-especially when dealing with metals or engineering-grade plastics.

CNC Milling

CNC milling uses rotating cutting tools to remove material from a fixed workpiece. It’s incredibly versatile and supports a wide range of geometries and materials.

Advantages:

- High-dimensional accuracy

- Excellent surface finish

- Ideal for flat and angled surfaces

Used in everything from aerospace brackets to aluminum housings, milling is a go-to for precision prototypes with tight tolerances.

CNC Turning

In CNC turning, the workpiece rotates while a stationary tool removes material-making it ideal for cylindrical parts like bushings, shafts, and pins.

Specific use cases:

- Axles and spindles

- Threads and grooves

- Round enclosures

Its efficiency and repeatability make it a staple for both prototyping and low-volume production of symmetrical parts.

What Are the Main Differences Between 3D Printing and CNC Machining?

To make an informed choice, it helps to see how the two methods compare side by side:

- Speed: 3D printing is generally faster for setup, while CNC excels in removing material rapidly once setup is complete.

- Material waste: 3D printing is additive, producing minimal waste. CNC machining removes excess material, generating more scrap.

- Surface finish: CNC machining offers smoother, more refined surfaces straight off the machine.

- Cost per unit: FDM printing is cheaper for small parts; CNC becomes cost-effective in metal or tight-tolerance parts.

- Part complexity: 3D printing allows intricate internal channels; CNC is limited by tool access.

- Tolerances and accuracy: CNC machines typically reach ±0.01 mm, while 3D printers vary (±0.025 mm for SLA, ±0.1 mm for FDM).

Which Materials Can You Use with Each Technology?

3D Printing Materials:

- Plastics: PLA, ABS, Nylon, PETG, TPU

- Metals: Stainless steel, Aluminum, Titanium (via metal 3D printing like DMLS)

- Composites: Carbon fiber-filled nylon, fiberglass-infused resins

CNC Machining Materials:

- Plastics: ABS, PEEK, Delrin, Polycarbonate

- Metals: Aluminum, Titanium, Brass, Stainless Steel

- Composites: Carbon fiber sheets, G10, laminated fiberglass

Which Method Offers Better Dimensional Accuracy and Tolerance?

Dimensional accuracy is a critical factor in functional prototyping. Here’s how the numbers typically stack up:

- FDM 3D Printing: ±0.1 mm

- SLA 3D Printing: ±0.025 mm

- SLS 3D Printing: ±0.05 mm

- CNC Machining: ±0.01 mm or better, depending on machine type and setup

If your prototype requires tight mechanical fits, such as enclosures for moving parts, CNC machining is often the better choice. For concept models or non-load-bearing prototypes, 3D printing usually offers enough precision.

Which Is Faster for Making a Prototype?

Speed can mean different things depending on context. Here’s how both methods break down:

- Setup time: 3D printing usually wins. Minimal prep and no custom fixturing.

- Turnaround time: CNC machining is quicker for certain metal parts once setup is complete.

- Post-processing time: SLA and SLS require curing and powder removal; CNC parts often need deburring but are closer to finished.

If you need a part by tomorrow morning and complexity is low, FDM or SLA printing can save the day. For robust parts with exacting features, CNC may be faster in the long run.

How Complex Can Your Prototype Be?

Geometry often dictates method. Here’s how the two compare:

- Internal channels: Easy in 3D printing, nearly impossible in CNC

- Undercuts: Possible with 3D printing; CNC needs special tooling or multiple setups

- Geometric limitations: Minimal in 3D printing; CNC restricted by tool shape and reach

- Tool access/support structures: CNC needs clear paths; 3D printing often needs removable supports

If your design looks like it belongs in nature-or science fiction-3D printing gives you that freedom.

When Should You Use 3D Printing for Prototyping?

- Early-stage concept models

- Complex organic shapes

- Lightweight structures

- Quick form studies and design iterations

- When multiple versions are needed fast

When Should You Use CNC Machining for Prototyping?

- High-precision components

- Structural performance testing

- Functional metal parts

- Tight-tolerance fits

- Low-volume production

What Are the Strengths and Weaknesses of Each Method?

Advantages of 3D Printing

- Rapid iteration

- Design freedom

- Minimal setup

- Low material waste

Disadvantages of 3D Printing

- Weaker mechanical strength

- Surface finish may require extra work

- Not ideal for bulk runs

Advantages of CNC Machining

- Exceptional precision

- Broad material compatibility

- Strong, functional parts

Disadvantages of CNC Machining

- More waste

- Longer setup time

- Limited to tool-accessible features

How Does Post-Processing Differ Between the Two?

- 3D Printing: Support removal, sanding, curing, painting

- CNC Machining: Deburring, polishing, coating, sometimes heat treating

Post-processing can add significant time depending on the finish required. SLA prints may need alcohol baths and UV curing, while CNC parts often go straight to finishing or assembly.

What Are the Software Requirements for Each Method?

- Design (CAD): Fusion 360, SolidWorks, Onshape

- Slicing (3D Printing): Cura, PrusaSlicer, PreForm

- CAM (CNC): Mastercam, Fusion 360 CAM, HSMWorks

The design process often starts the same-what changes is how the digital model is prepared and executed by the machine.

What Design Tips Should You Know for Each?

Design Tips for 3D Printing

- Avoid large overhangs

- Add fillets to reduce stress

- Optimize part orientation

- Follow wall thickness guidelines

Design Tips for CNC Machining

- Use standard drill radii

- Avoid deep cavities

- Keep consistent wall thicknesses

- Ensure proper tool access

Which Technology Is More Scalable for Low-Volume Production?

- 3D Printing: Great for low runs of 1-100 units, especially unique parts

- CNC Machining: Ideal for functional parts in small batches of 10-500+

Hybrid workflows are becoming more common-print to test, machine to perfect.

What Are the Environmental Impacts of Each?

- 3D Printing:

- Low material waste

- Lower energy for small parts

- Some resins are non-recyclable

- CNC Machining:

- Higher waste

- Metal chips often recycled

- Energy use depends on material and runtime

No method is entirely green, but 3D printing typically has the edge for sustainability in early prototyping.

What Are Common Mistakes to Avoid When Choosing a Prototyping Method?

- Choosing based on cost alone

- Overlooking tolerance needs

- Ignoring post-processing time

- Using SLA for mechanical stress testing

- Assuming one method fits all stages

Can You Combine 3D Printing and CNC Machining for Better Results?

Yes, and many engineers do.

- 3D print a bracket, then machine mounting holes

- Print a jig to hold irregular shapes for CNC cutting

- Use CNC to finish 3D printed metal parts for final tolerances

Hybrid workflows combine speed with strength and precision.

Real-World Case Studies: Who Uses What and Why?

- Aerospace: CNC for structural parts; SLS for light, non-load-bearing elements

- Medical: SLA for surgical models; CNC for implant-grade titanium

- Automotive: FDM for concept parts; CNC for under-hood prototypes

These industries don’t choose one-they mix both depending on the phase.

Comparison Table

| Feature | 3D Printing | CNC Machining |

| Accuracy | ±0.025-0.1 mm | ±0.01 mm or better |

| Speed | Faster for setup | Faster once setup |

| Material range | Limited (especially metals) | Extensive |

| Setup cost | Low | High |

| Design complexity | High | Medium |

| Repeatability | Moderate | High |

So, Which Should You Choose for Your Next Prototype?

Your decision should depend on your project’s exact requirements. Here’s a quick guide:

Choose 3D printing if:

- You need fast iterations

- Your part has complex geometry

- You’re testing form and fit

Choose CNC machining if:

- You need tight tolerances

- You’re working with metal

- You require functional or load-bearing parts

Often, the smartest move is to start with 3D printing and finish with CNC-blending speed with precision.

Conclusion

Choosing the right prototyping method isn’t just a technical decision-it’s a strategic one. By understanding the strengths and limitations of both 3D printing and CNC machining, you’ll give your ideas the best chance to come to life, perform as expected, and scale as needed.

Sometimes, the best answer isn’t either/or-it’s both.

Source: Raise3D