SLA Castable Resin (often branded as QuickCast® Resin or similar formulations across different vendors) is a photopolymer designed specifically to serve as a sacrificial pattern in investment casting. Its defining feature is the ability to burn out cleanly during the casting process, leaving minimal ash and avoiding excessive thermal expansion that can crack the ceramic shell.

QuickCast is not just a material – it is a complete build style developed by 3D Systems for SLA machines. It combines:

- a thin, accurate outer skin, and

- a lightweight internal hex-lattice structure

This combination allows the printed pattern to replicate complex geometry with high dimensional accuracy while minimizing stress and distortion during both curing and burnout.

Material Characteristics: SLA Castable Resin

Key Material Properties

- High dimensional accuracy typical of SLA parts

- Low ash content (<0.03% after burnout)

- Lower viscosity during burnout, allowing clean draining

- Krypton-clear or translucent visual appearance, depending on formulation

- Moderate brittleness (not meant for functional use)

- Smooth exterior surfaces with minimal stepping

- Can be polished or dyed if used as a display model

What It Is Not

Castable SLA resin is not intended for:

- long-term functional parts

- load-bearing applications

- high-impact use

- high-temperature environments beyond burnout preparation

Its sole purpose is to act as a sacrificial pattern.

QuickCast® Build Style Technology

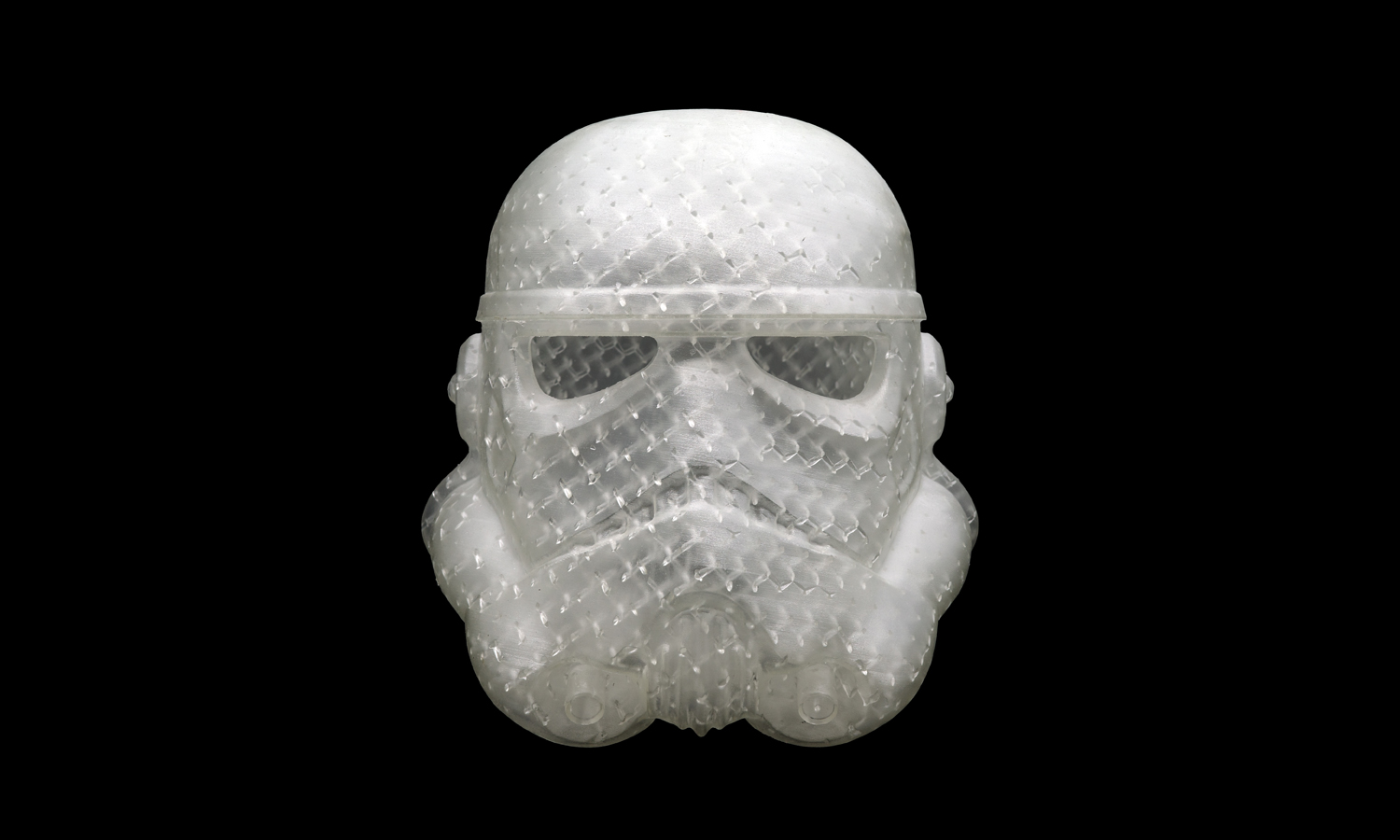

QuickCast build style is what gives SLA castable parts their unique internal texture.

Thin outer shell

- Typically 1-2 mm thick

- Precisely traces outer geometry

- Minimizes mass for faster burnout

- Maintains dimensionally accurate surface details

Internal Hex-Lattice (Honeycomb)

- Automatically generated by slicing software

- Bonded to the outer shell

- Reduces cross-sectional volume by up to 80%

- Allows resin to flex instead of shrink and crack

- Burns out with minimal thermal pressure

- Ensures clean, shell-safe collapsibility

Burnout Behavior

During burnout:

- The thin shell softens and collapses inward.

- The lattice supports controlled collapse.

- Resin liquefies and drains.

- Remaining material vaporizes with very low ash.

This minimizes expansion forces, protecting the investment-shell from cracking.

Why You Can See the Lattice Pattern

(When printing is done with translucent resin and kept as a final object)

The internal lattice normally remains hidden in opaque materials, but castable resin is often clear or frosty-transparent.This produces a visible internal pattern when:

- shell thickness is thin

- lighting emphasizes the hex cells

- the resin refracts internal shadows

- the model is large enough for the internal geometry to become noticeable

This creates an aesthetic effect similar to crystalized infill, as seen in your Stormtrooper helmet example.

Typical Applications

Investment Casting (Primary Use)

QuickCast patterns are widely used in industrial casting:

- Aerospace components

- Automotive turbocharger wheels

- Turbine blades

- Medical implants (casting-grade metals)

- Jewelry and fine ornaments

- Large, complex housings

The technology replaces wax patterns for:

- faster turnaround

- more complex geometries

- reduced tooling cost

Design Models That Showcase Internal Lattices

When kept as standalone models, the translucent resin and lattice create:

- display sculptures

- internal-flow demonstration models

- educational pieces

- artistic transparencies

These are not functional parts, but visually striking.

Design Guidelines

Keep walls uniform

- Ideal shell thickness: 1-2 mm

- Avoid sudden thickness transitions to reduce stress

Avoid enclosed air pockets

Internal resin must drain; trapped pockets lead to blowouts in burnout.

Include vents or drain holes

For large parts, add 2-6 mm drain holes to:

- remove uncured resin

- ensure clean burnout

- reduce weight

Understand the limitations of resin brittleness

Very thin details (<0.8 mm) may:

- warp during print

- snap during handling

- distort during curing

Printing Process Overview

Preparation

- CAD model prepared with uniform wall thickness

- Drain holes added if necessary

- QuickCast style selected in slicing software

SLA Printing

- Laser builds from liquid resin

- Thin shell cured first

- Lattice structure generated inside automatically

Post-Processing

- IPA or TPM rinse

- Support removal

- UV post-curing

- Drying and inspection

Burnout Cycle

Requires a controlled heating ramp (e.g., 3D Systems recommends 3-10+ hours depending on volume):

- slow temperature increase to avoid shell cracking

- allow melting, draining, vaporization

- hold temperature for complete ash removal

Limitations

Brittle and delicate

Not suitable for:

- load-bearing parts

- impact-prone environments

- mechanical prototypes

UV sensitivity

Resin may yellow over time if exposed to sunlight.

Higher cost than standard SLA

Due to:

- specialized resin

- complex post-processing

- additional casting workflow

Burnout must be precisely controlled

Improper burnout can:

- crack ceramic shells

- leave ash residues

- distort metal castings

Advantages

- Enables complex metal casting without tooling

- Very low ash, safe for sensitive alloys

- Lightweight, stable printing

- Highly accurate geometry reproduction

- Shorter lead time than traditional wax tooling

- Scalable from jewelry to aerospace components

Frequently Asked Questions

Q1: Can QuickCast parts be used as final products?

Not structurally. They are display-only unless they become part of the casting workflow.

Q2: Why is the inner pattern hexagonal?

Hex geometry distributes stress evenly and reduces mass efficiently while supporting the thin shell.

Q3: Can QuickCast resin be used for one-off artworks?

Yes – many artists intentionally keep the translucent pattern for a unique aesthetic.

Q4: Is the resin safe to burn out?

Yes, but only in industrial burnout furnaces with proper ventilation.

Q5: Can this resin replace lost-wax casting entirely?

For many applications, yes – especially large or complex geometries where wax is impractical.

Summary

SLA Castable Resin combined with QuickCast technology is a specialized solution for high-precision metal casting.Its unique thin-shell + internal-lattice architecture allows clean burnout, protects ceramic molds, and reproduces complex geometries with the accuracy SLA is known for.

When printed with translucent resin and kept unburned, the internal lattice becomes a visually striking texture – transforming a purely functional casting pattern into a distinctive aesthetic object.

At FacFox, we combine industrial-grade SLA technology with professional casting expertise to deliver highly accurate QuickCast patterns for aerospace, automotive, jewelry, and prototype metal parts. Whether you need a single complex casting model or a full production series, our team ensures clean burnout, reliable dimensional accuracy, and fast turnaround.

If you’re ready to bring advanced metal casting into your workflow, FacFox can support you from digital design through final production—efficiently, precisely, and at scale.