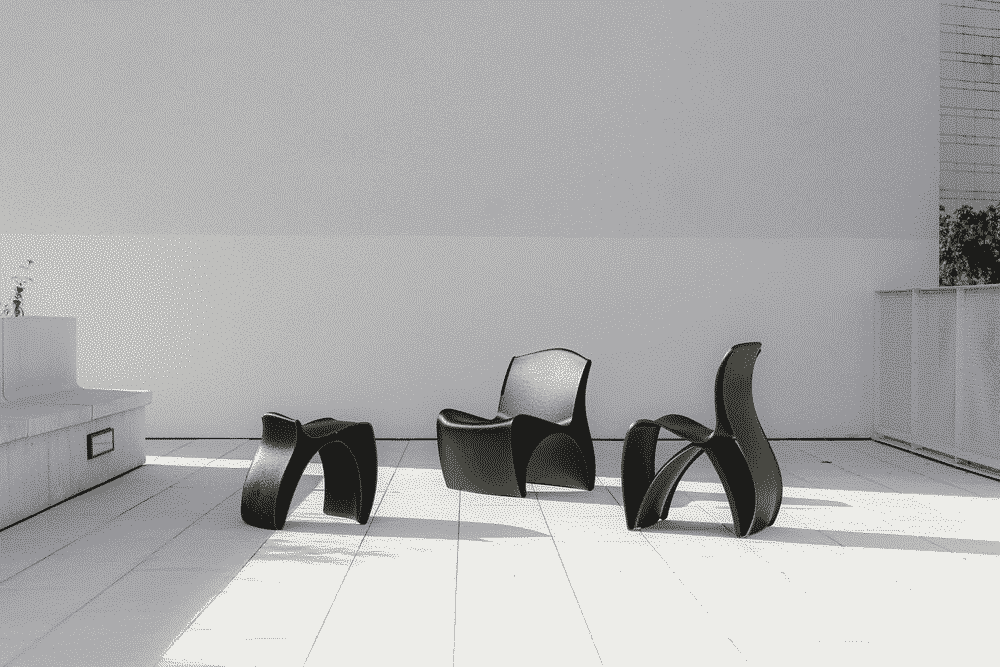

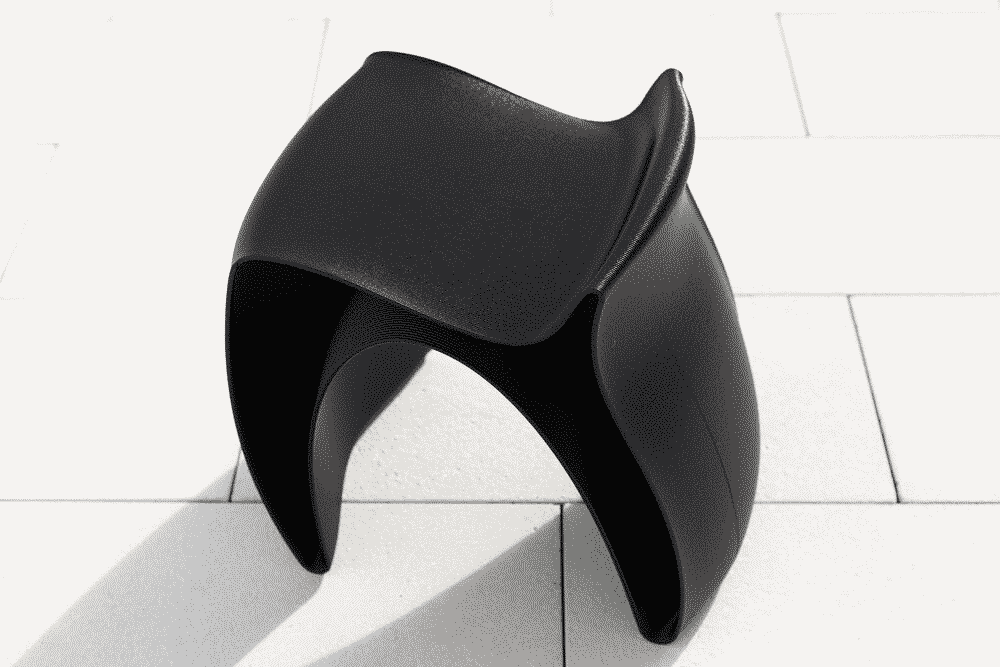

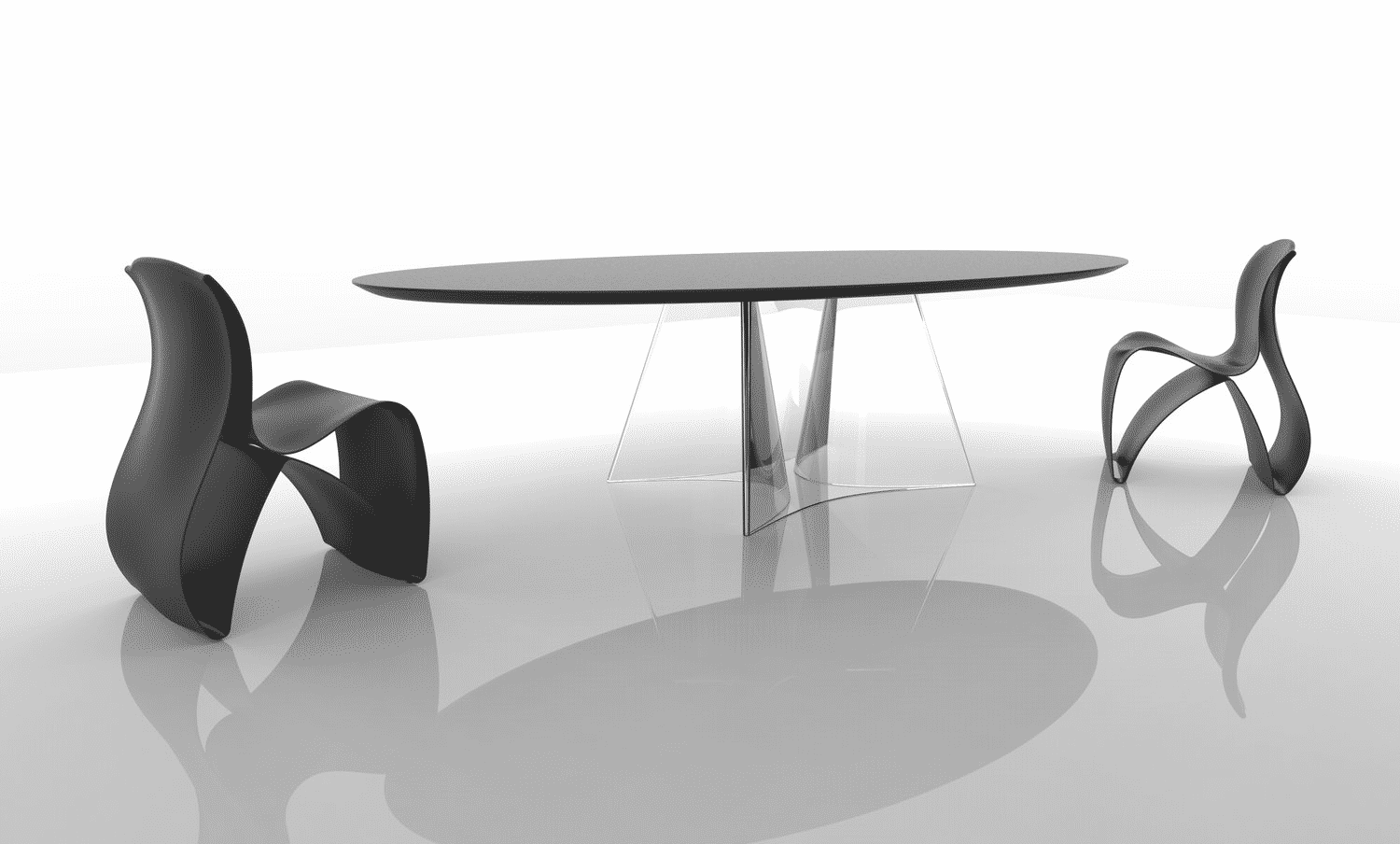

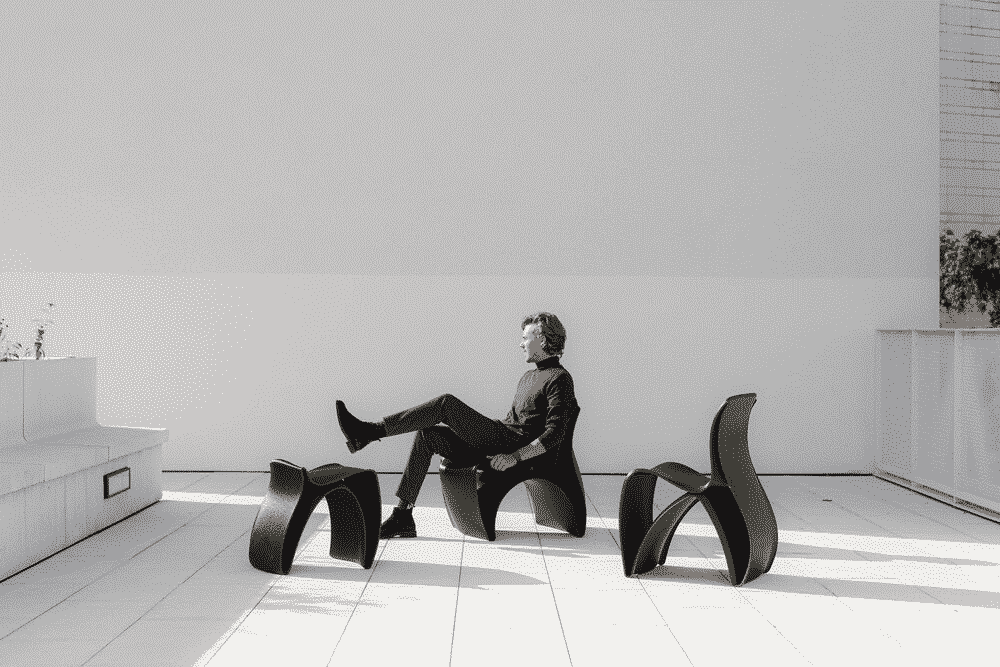

Belgian designer and artist Joachim Froment uses plastic waste as a raw material in his latest sustainable furniture collection. The “strat” is made from locally recycled plastic and 3D printed into seats and ottomans. The entire collection includes stools, lounge chairs and a variety of other furniture. The portable 3D printer used by the designer was developed by “Colosus”. This printer can be easily moved to the area where plastic waste is generated, which is very convenient.

Froment’s design of full-size furniture using a specific 3D printer can be completed in less than two hours. By reusing the plastic pellets produced in the recycling area in Belgium, the designer’s goal is to create products made from locally recycled materials, and then sell the products in the local market, while providing services for recycling products to provide people with a fully utilized furniture under circular economy.

Bringing technology into the design and perfecting it with common industrial processes, this approach also provides a new form of industrialization with great potential. Adaptable custom products also reveal new ways to create sustainable goods. This series of seats and other products are specifically designed according to the standard that can complete 3D printing within a certain time frame, and at the same time, it can achieve the most efficient use of materials and avoid waste to the greatest extent.

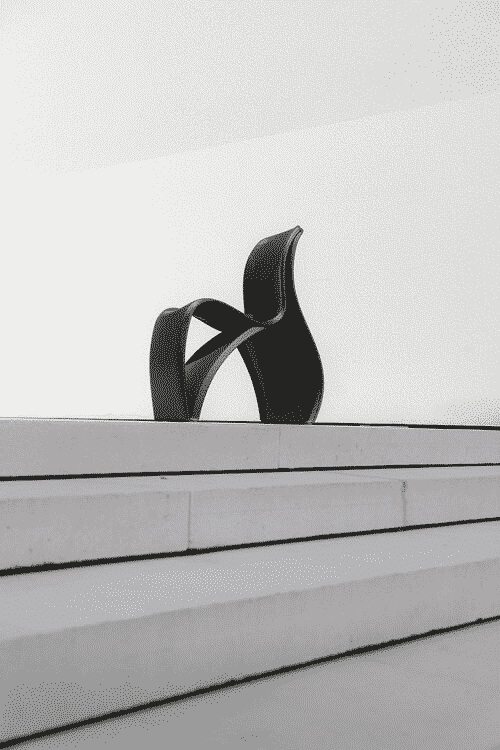

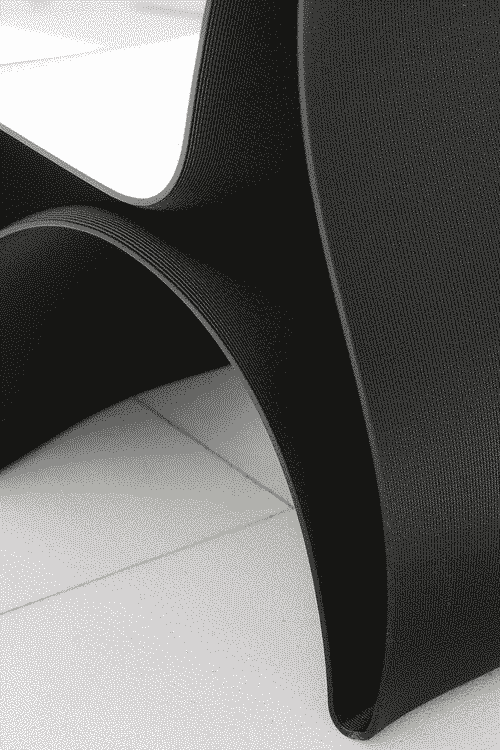

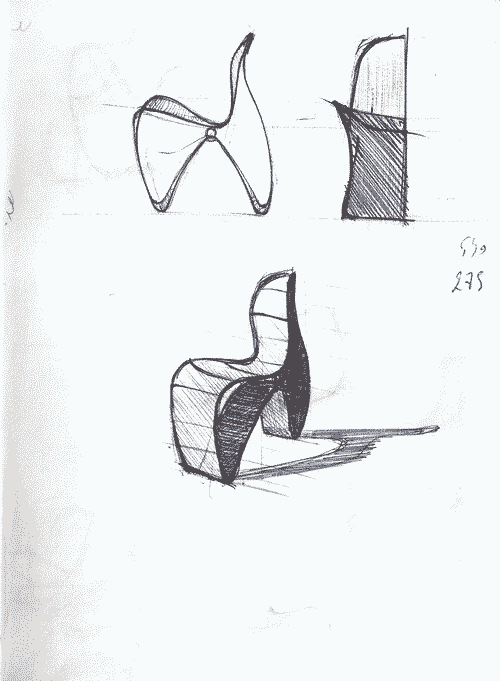

The closed-loop shape of this seat enhances the mechanical strength of the structure and also follows the “Vase Mode” process, which ensures that the product can continue to print without interference. The entire production process greatly saves time and energy. The organic soft curve of the seat creates a unique sense of lightness, which clearly shows the importance related to the product’s raw materials. The curve also strengthens the mechanical properties, which is also a necessary condition for strengthening the seat structure.

It is reported that this series of products will be sold in the Benelux market from November 2019. In the next few months, it will expand its production in Europe through export products.

All pictures have been photographed by Eline Willaert / MAD, Home of Creators