No need to be scared! 3D printing ghosting or ringing is nothing to fear. Check out this quick guide for easy fixes to prevent it.

Ringing, also known as ghosting or rippling, is a 3D print quality issue that can hurt the visual appearance of a model. You can usually spot ringing on a print if you notice that a part’s exterior walls look rippled, wavy, or just not smooth. Ringing can also cause dull edges and corners on prints, such as when including text on prints.

This visually destructive print quality problem occurs on 3D prints when the nozzle is prevented from laying down material in a controlled manner, creating a constantly shifting print environment. The ripple effect on the sides of prints is the result of the vibrations in layers, too high a printing speed, and a displacement in the printing area.

It’s important to understand the difference between ringing and layer shifting, as they are easily confused. Layer shifting usually results in a printed model that shifts in the same direction after every layer, while ringing causes layers to shift in multiple directions, back-and-forth. Also worth mentioning is the difference between ringing and visible infill; the latter occurs when your wall thickness is too thin and allows your infill to bleed through the model.

Now that we know what ringing is (and what it’s not), let’s go over three main solutions to ringing, with some other tips to try if the issue persists.

Solution #1: Tighten Your Belts

Your printer likely uses belts to move a component (or multiple), such as the printhead and print bed. Over time, these belts can stretch or the pulleys that hold them can loosen, allowing slack to get into the belt loop. When this happens, the printhead (or whichever component uses belts) will move around during printing, causing ringing in prints.

To solve this, you can tighten your printer’s belts. The process varies depending on the printer model, but it usually involves tightening a screw on the pulley to pull the belt taut. A good rule of thumb is to tighten your machine’s belts until you can flick one with your finger and it barely bounces, but don’t tighten them too much, as this can decrease their longevity.

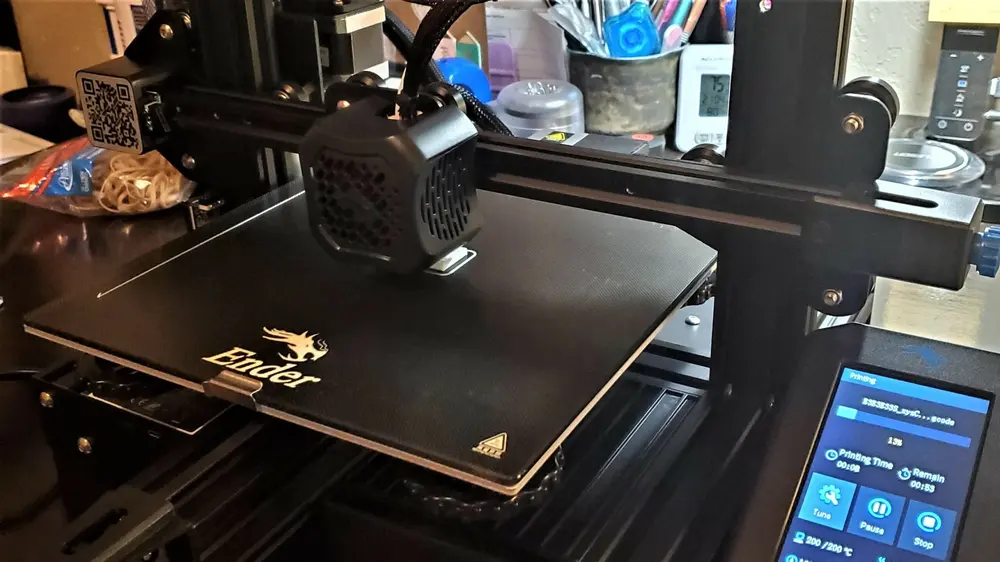

Some machines, like the Ender 3 V2, also have integrated belt tensioners with thumb screws that allow you to easily adjust the belt tension. If your printer doesn’t have these, there are 3D printable upgrades.

Solution #2: Slow It Down

The faster your print speed, the faster your printhead will move and the more vibrations the nozzle will experience during printing. There will also be quicker direction changes, which can exacerbate ringing on your print. For these reasons, our next solution for ringing is to print more slowly, which you can do by adjusting the speed settings in your slicer.

It’s important to mention that you shouldn’t be lowering your default print speed (around 60 mm/s for PLA) by more than about 25%. If significant reductions in your print speed don’t solve ghosting, then chances are your speed isn’t the cause. If you think that changing the speed is the right solution, though, print a test model a few times, starting at your current speed and reducing it in increments of 5 mm/s until surface quality improves.

Solution #3: Find a Solid Base

One of the best ways to reduce vibrations is to print on a solid and steady base. Ideally, you want to place your printer on a stable, flat surface, like a level table, where vibrations will be minimized because components will be secure and won’t shake.

Using an additional form of vibration dampener can further help reduce ringing’s impact on your prints. Nowadays, most printers also come with pre-installed rubber feet that help make the printer remain stable on the ground (or wherever it’s placed). If your machine didn’t come with rubber feet, you can also DIY some or purchase a couple.

Other Solutions

The three solutions we presented are your most likely bet to fix ringing. However, there are also other ways you can try to solve this print quality issue:

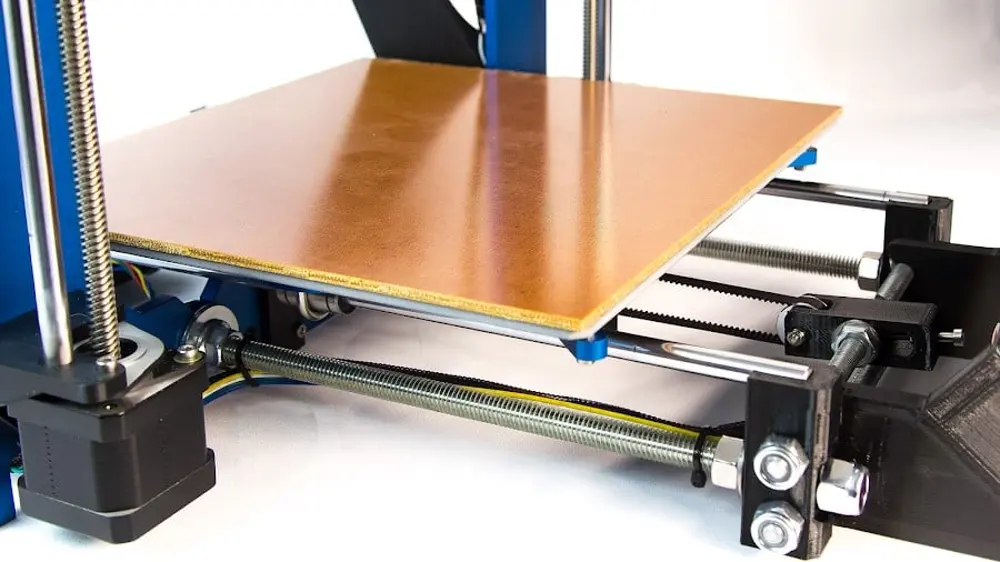

- Use stiffer springs: One way the build plate on a 3D printer can move is if the springs that allow you to level your bed are loose. Using stiffer springs can help keep your build plate steady, minimizing vibrations on the print and preserving the evenness of the build plate.

- Lower acceleration and jerk: Acceleration and jerk (the derivative of acceleration) are key settings for 3D printing that control how fast the printhead speeds up and changes direction. With models that involve a lot of direction changes, lowering these values can help prevent ringing as direction changes are smooth and less sharp.

- Adapt your design: Lastly, tweaking the design of your print can help prevent ringing. If you limit the number of direction changes in your model, you can significantly reduce ringing in prints.