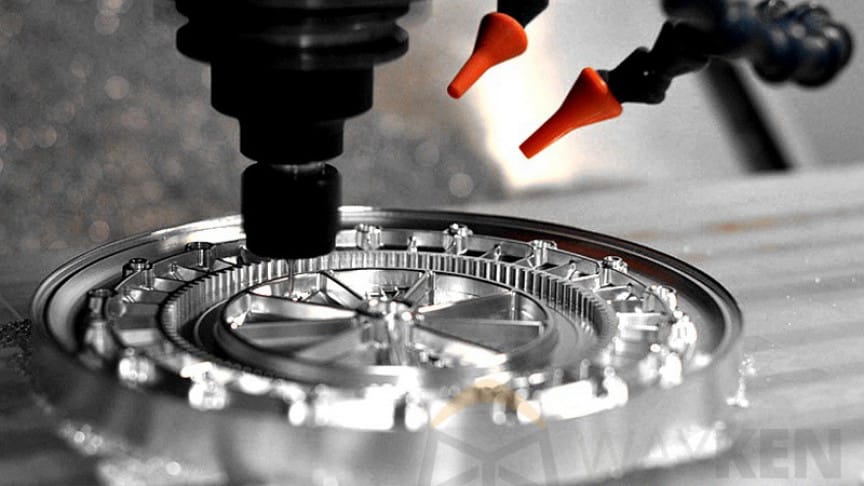

CNC (Computer Numerical Controlled) machining is a means to remove the material with high precision machines, using a wide variety of cutting tools to create the final design. Common CNC machines include vertical milling machines, horizontal milling machines, lathes, and routers.

To successfully make a part on a CNC machine, skilled machinists create programmed instructions using CAM (Computer-Aided Manufacturing) software in conjunction with the CAD (Computer-Aided Design) model provided by the customer. The CAD model is loaded into the CAM software and tool paths are created based on the required geometry of the manufactured part. Once the tool paths are determined, the CAM software creates G-Code (machine code) that tells the machine how fast to move, how fast to turn the stock and/or tool, and where to move the tool or workpiece in a 5-axis X, Y, Z, A, and B coordinate system.

With 600+ industrial 3D printers (FDM, SLA, DLP, MJF, Polyjet, SLS, DMLS/SLM), 200+ CNC machines, and 100+ material options, FacFox is the largest online digital manufacturing service provider in China. Rapid prototyping service as fast as 48 hours. Worldwide shipping.

Types Of CNC Machining

There are several types of CNC machining — namely the CNC lathe, CNC mill, CNC router, and Wire EDM.

With a CNC lathe, the part stock turns on the spindle and the fixed cutting tool is brought into contact with the workpiece. Lathes are perfect for cylindrical parts and are easily set up for repeatability. Conversely, on a CNC mill the rotating cutting tool moves around the workpiece, which remains fixed to a bed. Mills are all-purpose CNC machines that can handle most any machining process.

CNC machines can be simple 2-axis machines where only the tool head moves in the X and Z-axes or much more complex 5-axis CNC mills, where the workpiece can also move. This allows for more complex geometries without requiring extra operator work and expertise. This makes it easier to produce complex parts and reduces the chance of operator error.

Wire Electrical Discharge Machines (EDMs) takes an entirely different approach to CNC machining in that they rely on conductive materials and electricity to erode the workpiece. This process can cut any conductive material, including all metals.

CNC routers, on the other hand, are ideal for cutting soft sheet materials such as wood and aluminum and are more cost-effective than using a CNC mill for a similar job. For harder sheet materials such as steel, a waterjet, laser, or plasma cutter is required.

Advantages of CNC

Rapid Turnaround

Using the latest CNC machines, Xometry produces highly accurate, quick turn parts in as fast as 1 day.

Precision

Offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs.

Custom Finishes

Select from a variety of finishes on solid metal and plastic parts, built to precise design specifications.

Scalability

CNC Machining is perfect for the production of 1-10,000 parts.

Material Selection

Choose from over 50 metal and plastic materials. CNC Machining offers a wide variety of certified materials.

CNC Finishes

As-Milled

The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. The surface finish is comparable to 125 uin Ra finish.

Bead Blast

The part surface is left with a smooth, matte appearance.

Anodized

We can creates a corrosion-resistant finish and anodize parts in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum. The finish can be thicker and creates a wear-resistant layer in addition to the corrosion resistance.

Powder Coat

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Custom

Haven’t seen the finish you need? Submit your requirements and we’ll look into a finishing process for you.