Compared with traditional building construction methods, 3D printing technology has the following advantages:

- Printed in one piece which enhances safety and durability.

- Tailored construction according to users’ actual needs.

- High accuracy and able to build complex structures.

- Unmanned operation in a harsh environment.

- Saving a lot of on-site personnel.

- Fast construction speed.

- Local additive processing.

The following are useful attempts and reflections in the research of 3D printed architecture:

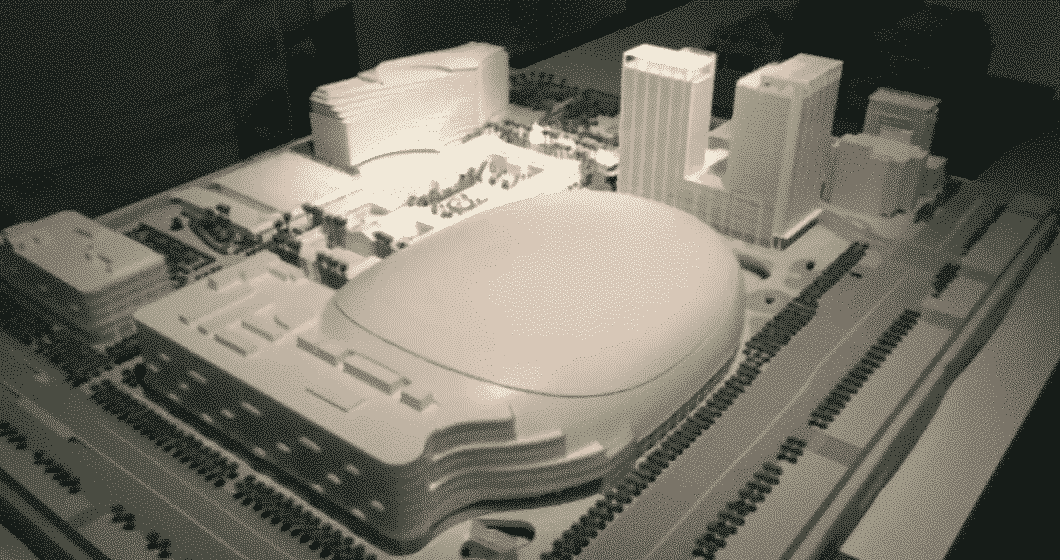

Application: Presentation Model

The architectural presentation model often takes weeks to make by hand, while 3D printing takes only a few days.

Architects can use thermoplastic materials to make models by 3D printing, then polish, polish, paint or electroplate the parts of the presentation model, and finally achieve the appearance and texture that the model needs to express. 3D printing is not only suitable for complex appearances, but also can improve the compactness, strength, and durability of the model.

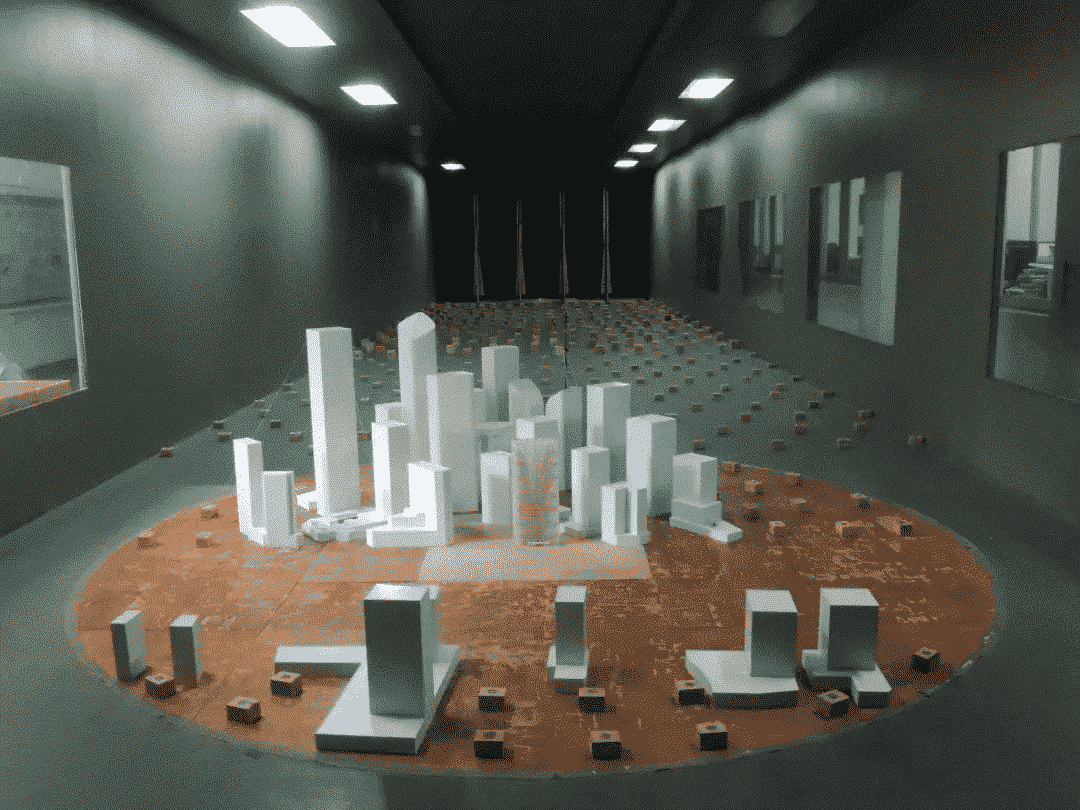

Application: Wind Tunnel Testing Model

Wind load is one of the main lateral loads of high-rise buildings, and structural wind resistance analysis is an important part of the structural design of high-rise buildings.

For complex structures, the existing codes do not determine the specific values of the wind pressure distribution on the building surface. Wind tunnel tests on structural models are needed for simulation and determination. The wind tunnel test not only provides the overall wind load distribution of the structure, but also the wind load distribution on the wall surface. For wind tunnel test, you can try to make a small scale model (usually 1: 400) using 3D printing technology.

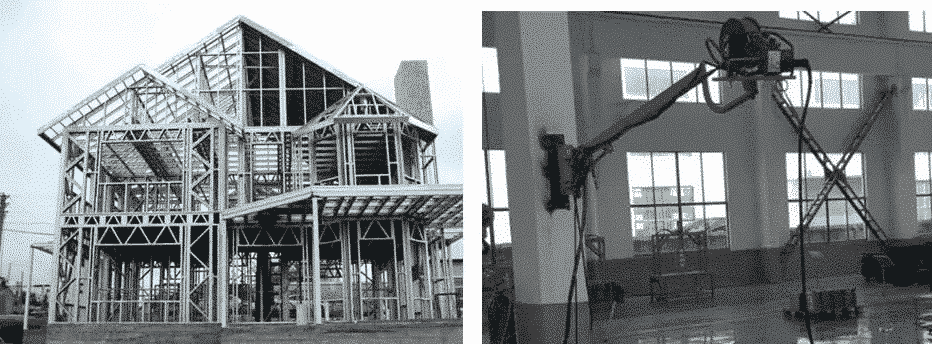

Application: Repair and Strengthen Steel Structure

When the existing steel structure buildings need to increase or repair the cross-section of the original structural component due to changes in functions, expiration of service life, and corrosion, etc., 3D printing can be applied.

The materials of steel structures are metals. The technology of printing aero engines can be used on steel structure buildings. And the new and old materials can be completely and seamlessly integrated through FDM (fused deposition molding technology) or EDM (electron beam melting technology). Before using these technologies, the size and lifting range of the printer need to be addressed to meet the demands of construction.

Application: Building in Outer Space

When mankind expedites outer space and tries to settle on an alien planet, it is necessary to apply 3D printing of the planet’s materials to build a living place for human survival.

The French design company Fabulous inspired the concept scheme named “Sfero”. The construction of dwellings and camps in the space environment is more difficult than the earth. We need to solve the transportation and energy problem of 3D printers.

After preprocessing, the metals and minerals on other planets can become basic building materials that are safe, heat-resistant and durable.

3D printing equipment can be used in outer space, no matter it’s weightless or overweight, dry or extremely wet. High-temperature differences or strong airflow interfere can never stop it working and converting building basic materials into final products.