The top-notch construction companies have already tried using 3D printing in building residential architecture. Some of them successfully made multi-story buildings, but find it’s not that simple with 3D printing. In other words, we all know that 3D printing must become the future of architecture, but it’s still a long way from where we stand. Here are a few cases from the companies who made it. You can see that if some of the problems are not pre-solved, 3D printing is not as effective as the traditional method currently.

Case 1: 3D Printed Building By Suzhou Yingchuang

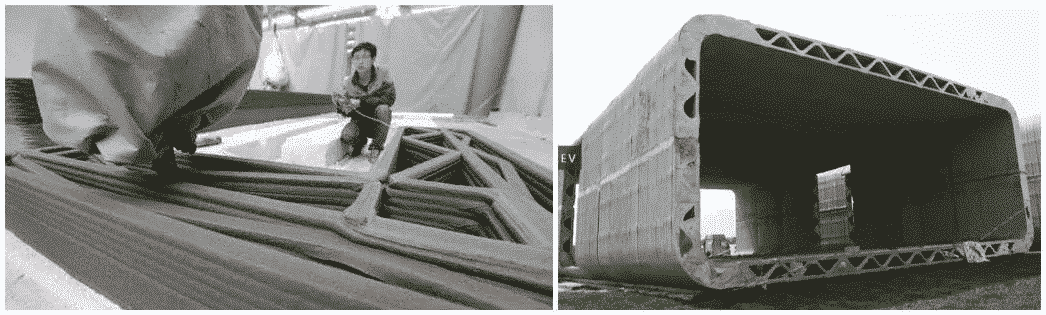

Suzhou Yingchuang Co., Ltd. built a villa with an area of 1,100 square meters and a 6-story residential building in Suzhou Industrial Park in January 2014, using 3D printed components.

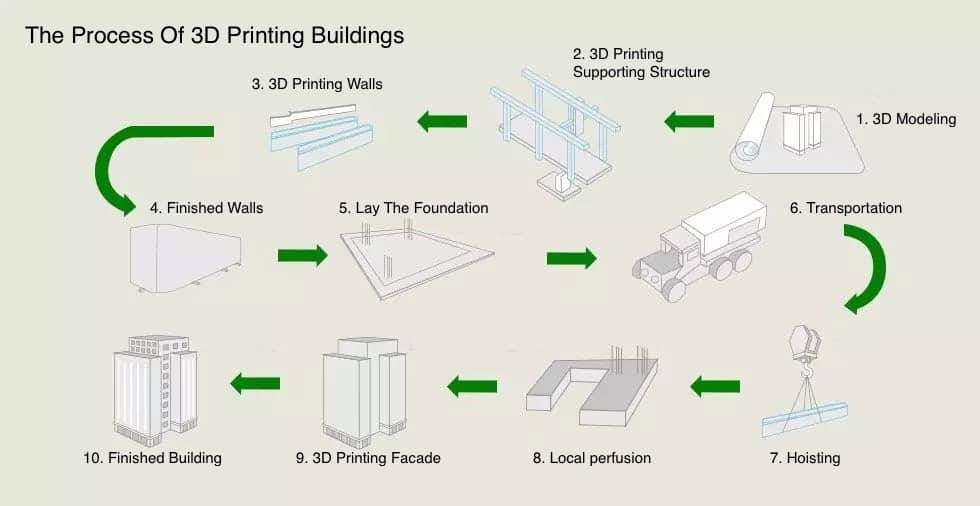

Yingchuang adopts corresponding solutions to the technical problems during 3D printing:

- They use cement and glass fiber as raw materials and print GRC-like components. Compared with traditional reinforced concrete structures, cement is used to replace concrete while fiberglass replaces steel. There are subsequent issues that need to be further solved, such as:

- The stress test of cement fiberglass components;

- The calculation of the ultimate state of the bearing capacity of cement fiberglass components;

- The anchoring overlap structure of glass fiber in cement, and the quality acceptance criteria of components, etc.

- The 3D printer uses a gantry structure to easily convert the traditional concrete pouring method to a 3D printing method. Through an automatic positioning system, they can accurately locate the placement of steel mesh and other decorative components, reducing labor force and errors.

- The problem of the limited size of printed components is solved by assembling. One of the key technologies is to use the “double skin wall” principle to solve the problem of external facing, buried pipelines, and structural connections.

Yingchuang Company solved the technical problems of the low-rise or multi-story buildings, and formed a complete set of practical solutions. It can be further improved in aspects such as the improvement of the apparent quality of the printed components, the integration of the thermal insulation as well as decoration, etc.

Case 2: 3D Printed Castle By Beijing Huashangluhai Company

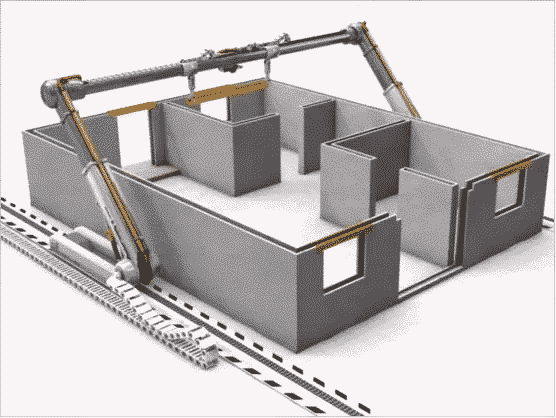

Beijing Huashang Luhai Technology Co., Ltd. developed a gantry-type building 3D printer with reference to the gantry crane, and printed a 600-square-meter three-story physical building “Windsor Castle” in Hebei in early June 2018.

The building is about 30 meters long and 11 meters wide. The 3D printing method has truly realized on-site printing, and the raw materials are ordinary reinforced concrete. Through the direct casting and molding technology, the formwork process has been eliminated, and the cost, as well as the construction period, have been correspondingly reduced.

- The printing material of “Windsor Castle” is concrete. Rebar engineering is the same as the traditional construction method and requires pre-bundling;

- By optimizing the concrete mix ratio and adding necessary additives, the molding stability and initial setting progress of the concrete after printing have been improved;

- Due to the elimination of formwork and vibration, the quality of printhead, and the printing surface of the concrete, the printing effect is so poor and needs thick plastering or other post-processing, which increases the corresponding cost;

- The print head still needs manual assistance to control the position during the movement, and cannot directly pass through the “T” joint of the vertical and horizontal walls;

- The concrete protective layer is too thick, and the stress status of the wall outside the plane is not good;

- The installation period of the 3D printing equipment is not as short as you think. Therefore, the actual construction period of the main structure of the “Windsor Castle” is 45 days, which is close to the traditional construction period of the same type.