Materials are the “blood” of 3D printing, which is related to the construction of the 3D printing ecosystem and the sustainable development of the industry. Only when consumables and equipment are advanced synchronously, can the marketization process of 3D printing be promoted, and the transformation of 3D printing from design concept to prototype manufacturing be realized.

As a result, more and more enterprises are investing in the research and development of 3D printing technology and related supporting materials. Each manufacturer has also continuously launched its own new technology or new products. The research and development of new 3D printing materials will be the next explosion point of 3D printing. Among them, flexible 3D printing materials are the most attractive.

The flexible filaments have strong toughness, adapt to certain deformation and expansion, and are not easy to crack. They are widely used in medical treatment, automobile, footwear, and other fields. Facfox can offer the following materials and recommend the most common applications of them.

TPE

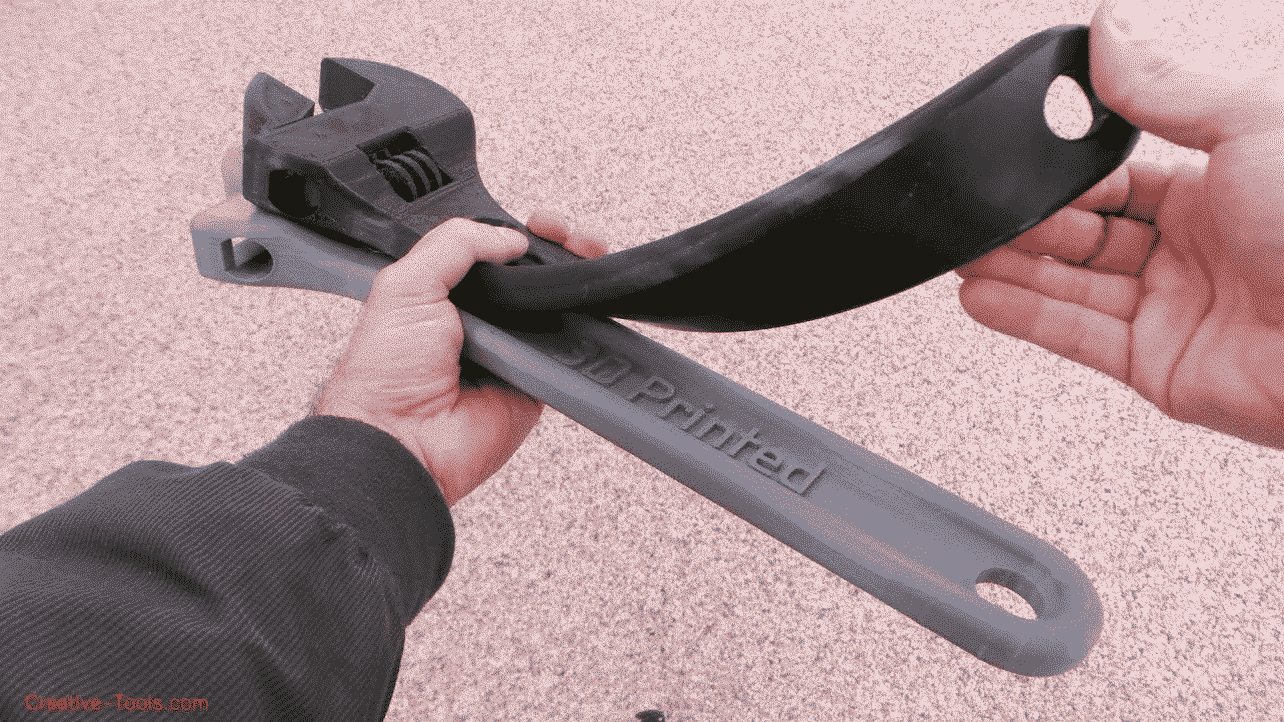

TPE is one of the most flexible and durable 3D materials on the market today. It is easier to obtain and is softer than other flexible 3D printing materials on the market.

As a very popular flexible filament, TPE is composed of thermoplastic elastomer, which is the most popular flexible material in 3D printing. It is a plastic similar to the rubber.

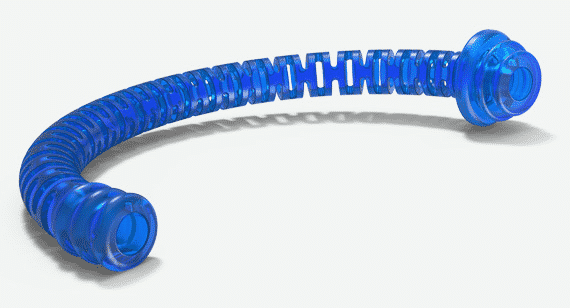

TPE filament can be used in a wide range of fields. It really fits into the energy industry which has a vast demand for making prototypes of wire and cable, fiber optic and other electrical applications. Marine and automotive industries are turning to use TPE rather than thermoset rubbers as the former ones can increase efficiency.

Regarding safety reasons, TPE is a perfect choice to make the prosthesis. Food contact TPE is often found in baby spoons and toddler cup spouts.

TPU

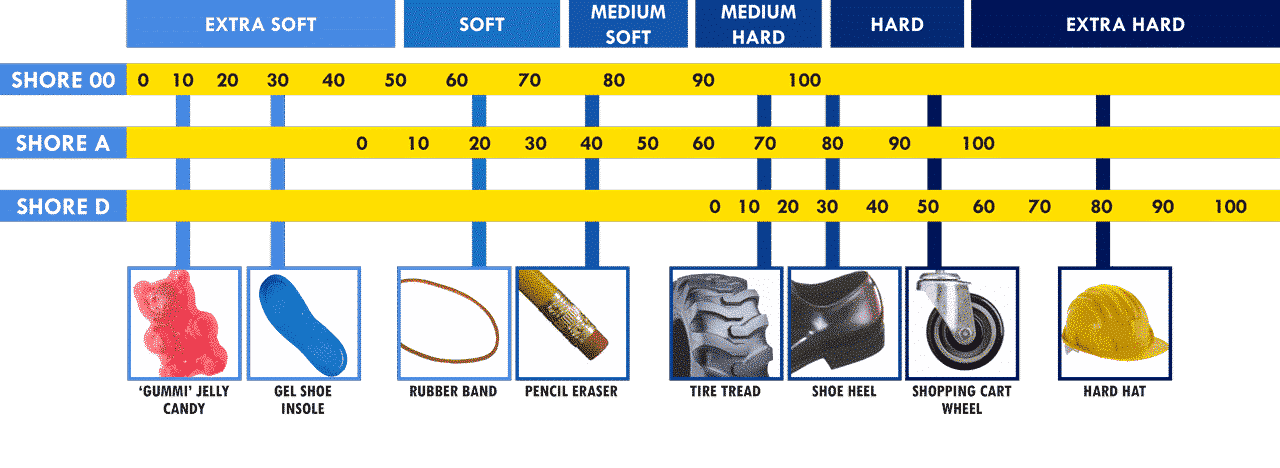

TPE (Thermoplastic Elastomer) and TPU (Thermoplastic Polyurethane) are the most well-known flexible material. Although having two different names, TPU is actually a type of TPE material; the main difference between them is mainly in Shore hardness. Plastics called as TPU are usually tougher, their hardness is somewhere around 60A-90A on the Shore hardness scale (see below).

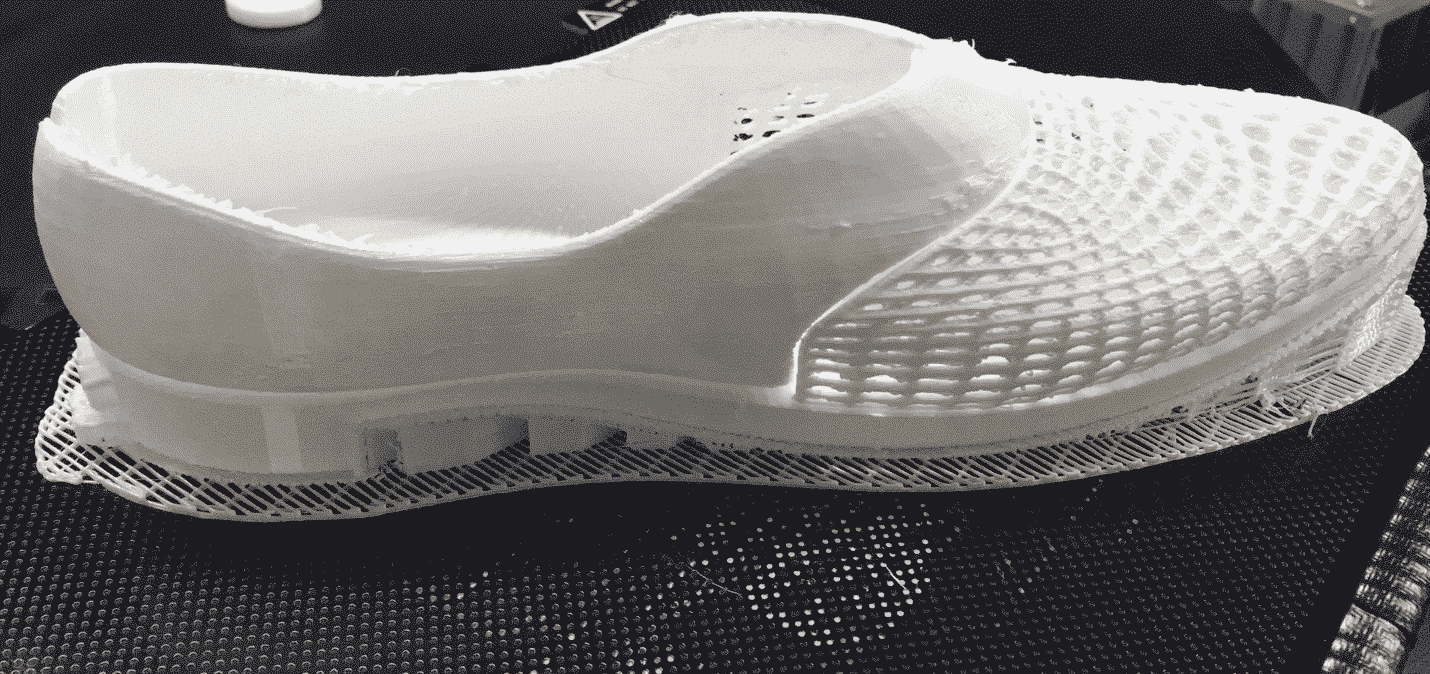

Compared to TPE, TPU is a little bit easier to print and retains its elastic properties better at lower temperatures. TPU material also has higher abrasion resistance and higher resistance to oils and greases. It also has an excellent interlayer adhesion and no curling or delamination during the 3D printing process.

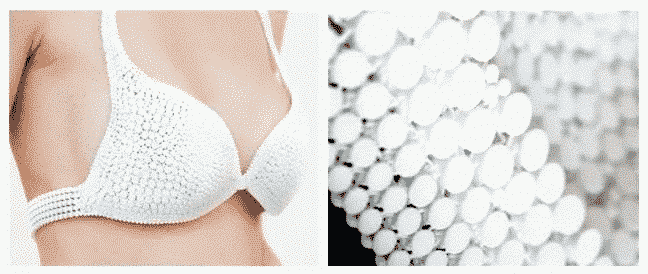

TPU printed objects own both high elasticity and hard-wearing qualities, thus they are commonly used as training aids, water equipment, and fitness equipment. Footwear has to withstand low temperatures, flexibility and be resistant to water and chemicals. TPU surpasses TPE in footwear applications. Besides, aerospace and automotive both adopt TPU in instrument panels, sensors and levers as well as many other areas.

Nylons

Nylons and TPE are both soft and many of the same rules apply to both of them. There are a few different Nylon base types that will be used for 3D printing, and those are PA6, PA6.6, and PA12. PA 6 is the softest one and the one that absorbs moisture the fastest. Some PA6-based filaments will become unprintable within hours if left out in the open. PA6.6 is a bit less sensitive there and PA12 is generally the least moisture sensitive.

Nylons are well-known in making functional prototypes and end products, however, it’s also the first material used for making women’s stockings. Nowadays, it appears in cosplay costume making, insoles producing, and prosthesis customization, just as how TPE and TPU are applied. Besides, scientists begin to expand the use of Nylon into the quick-drying swimsuit.