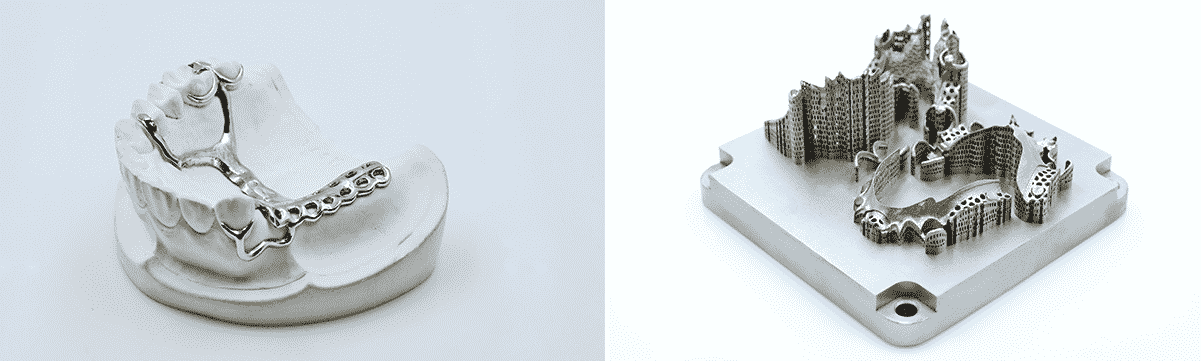

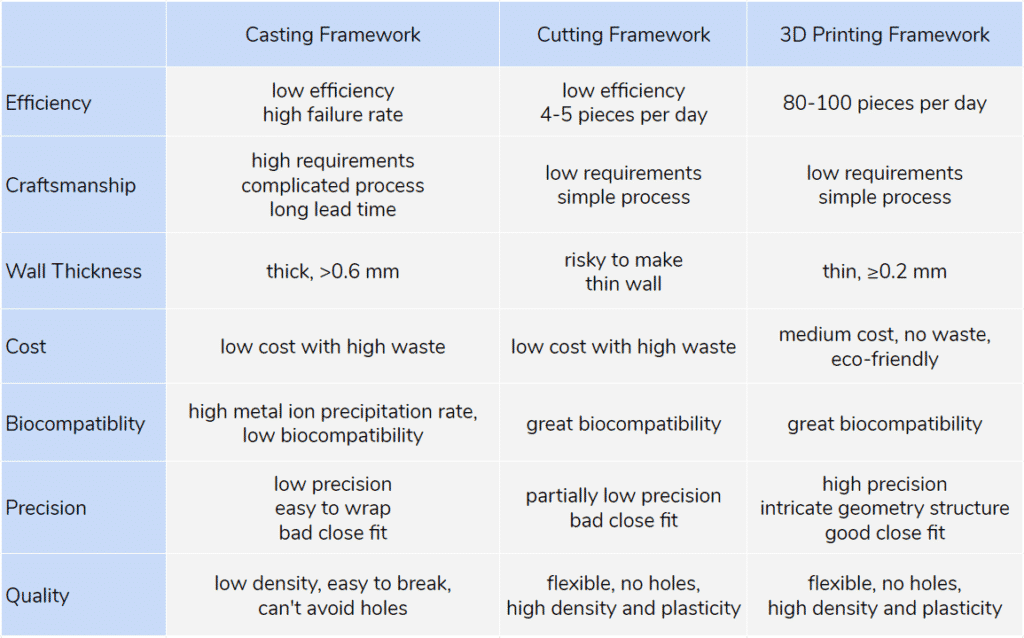

The metal dental framework is the best choice for the restoration of multiple teeth loss and is also the most commonly used repair method after implantation surgery. In the traditional process, the metal casting framework has a strong dependence on manual work, thus results in low production efficiency.

Besides, due to the uneven craftsmanship level, the framework is prone to deformation. Moreover, the casting of a pure titanium denture framework is more difficult, and it was once regarded as an embarrassing product by the dental technology factories.

In recent years, due to the lack of skilled technicians, less and less experienced technicians, the pure titanium denture support industry “even worse”.

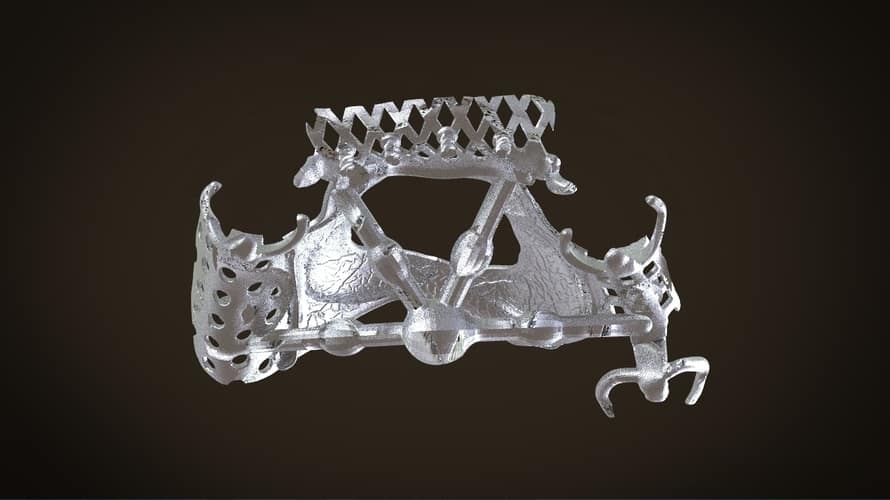

The 3d printed titanium framework can avoid the above problems with perfect adhesion (nearly 100% customization) and extremely high density; it reduces the waste of raw materials (powder can be used repeatedly), and the production process is environmentally friendly. We have estimated that the overall cost of the 3d printed titanium framework is only half of the traditional framework.

Pure titanium is known as a biological metal with many good properties.

- Titanium has stable chemical properties and excellent biocompatibility and does not react with human tissues. It does not cause gingival inflammation, black tooth edge, oral metal odor, or other problems.

- Pure titanium is non-magnetic and does not affect MRI, X-ray radiography, CT and other medical examinations in the future.

- Small specific gravity, lightweight and low foreign body sensation.

- High strength, corrosion resistance, low thermal stimulation, safe and reliable.

- Pure titanium has become one of the most important medical metal of the 21st century.