In the field of car tuning, the most eye-catching parts where car enthusiasts (a.k.a. gearheads) could show their great creativity, are the front bumpers, grilles, and tails. However, it’s hard to open molds for low-volume production because of the limited demand for each modified component. In consequence, gearheads and car modification shops have to face the annoying problems like high customization cost, long development period, immature technique, etc. We have summed up below mature techniques for front bumper customization after the long-term producing experience.

Direct 3D Printing

The best choice for manufacturing 1-10 products is 3D printing. The advantage is fast production, low cost and smooth surface for painting and electroplating. However, the tenacity of the material is lower than ABS, which may break during production. Durability is unsatisfactory enough either, aging and cracking may happen after longtime outdoor exposure.

With the improved process and upgraded equipment, the entire front bumpers could be directly 3D printed in one piece. Imported high toughness material could ensure precision and high strength.

Urethane Casting

Urethane casting is the best option for the production of 10-100 products. Its shortcomings are the limited service life of the urethane mold (around 20-50 times). The total cost for over 100 pieces of production would be higher than the die.

Urethane casting is an enhanced process. Compared with the traditional membrane process, urethane casting leads to lower cost, higher precision, shorter lead time and is less reliable on the labor force. It has become the mainstream for batch customization of bumpers, interior decorations, and center control panels.

Reaction Injection Molding

Reaction injection molding (RIM) completes low-volume production by injecting polymers into a resin mold under low pressure. It’s usually used to produce automobiles and electronic components. Its strengths include long service life of mold (generally 100-200 times), cheap and high tenacity materials; in the meanwhile, the material range is restricted, and bubbles often emerge in the surface so the finishing process takes a long period. RIM is suitable for a volume of 50-200 large-size products.

With improved RIM molds, the finish process time has been shortened and the surface is much more smooth than before. Currently, RIM is the main process for bumpers production.

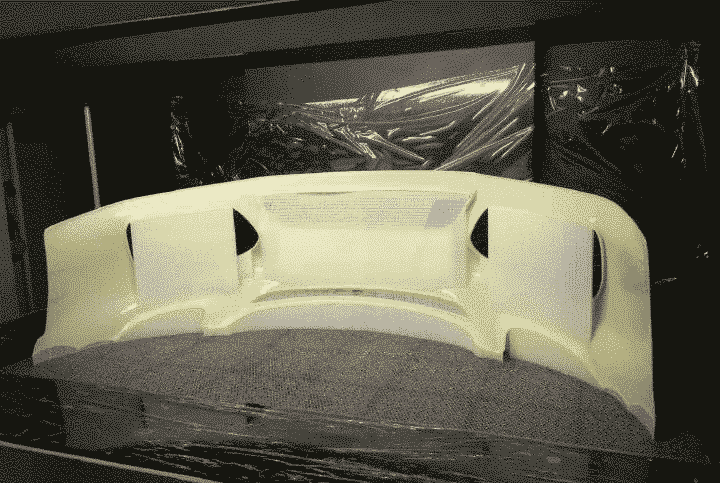

Fiberglass Molding

Fiberglass, also known as glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or GFK from German, is a type of fiber-reinforced plastic using glass fiber. It’s strong but light-weight, non-conductive, fine stability, high mechanical strength, low waste, and corrosion-resistant. It could replace steel in manufacturing machine parts, shells of automobiles and ships, etc. This process has a low production cost but relatively high labor cost and causes environmental pollution. It has been gradually replaced by other processes.

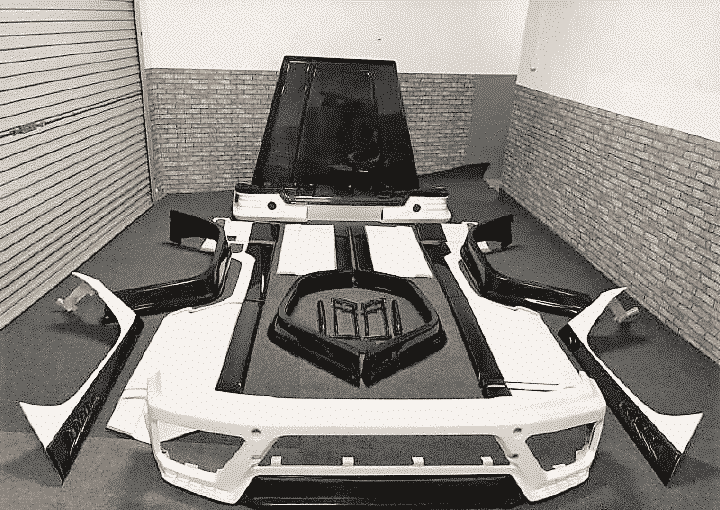

Simple Molding

Simple molding is one kind of rapid molding targeted at low-volume production. It cuts down 2/3 of the cost and spends only 1/2 time than the traditional method. It’s the most preferred technique if you require high precision and smooth surface of the products. Considering the composite cost, the recommended volume is 100-1000 sets.

There are other techniques including CNC, high-pressure infusion, formal molding, etc. We will help you choose the best materials and producing techniques according to your purpose, requirements, budget and lead time.