Despite the growing popularity of sustainable practices, most Americans still don’t have an efficient or cost-effective way to recycle FDM 3D printing scraps. In many cases, buying new filament is just easier than reclaiming waste.

Why So Many Scraps?

FDM 3D printing, especially with PLA, is notorious for generating large amounts of waste. Here’s where it comes from:

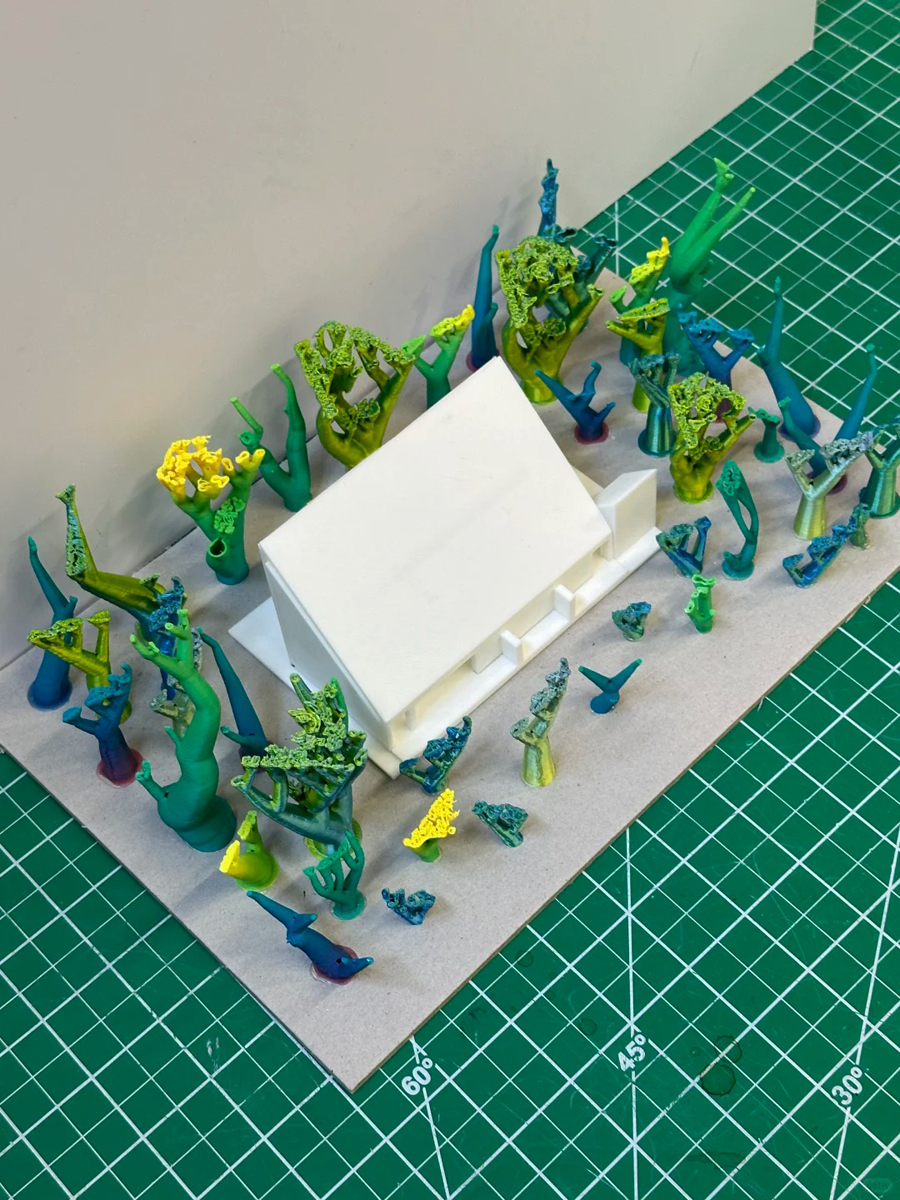

- Tree supports and rafts: Particularly in complex or organic models, tree-style supports can account for 30-80% of a print’s material.

We are never so efficient in planting trees. - Failed prints: Misprints, under-extrusion, warping, or bed adhesion issues are common even for seasoned makers.

- Prototyping: Designers may go through many iterations to fine-tune a model.

- Brims, skirts, and test prints: Small but accumulative waste that builds up quickly.

- Multi-color printing: This is a big one. Whether you’re using a multi-material unit like the Bambu AMS or Prusa MMU, every color switch purges the nozzle, generating long strings of filament waste. Complex models with many transitions can produce more purge waste than the actual part itself.

The scraps weigh much more than those Pokémons.

The scraps weigh much more than those Pokémons.

So if you’re printing a colorful figurine with 20 color swaps? Prepare to clean out a mountain of spaghetti.

What Are Americans Doing With PLA Waste?

Unfortunately, recycling PLA in the U.S. isn’t as easy as tossing it in the green bin. Here’s what people are trying:

1. Composting PLA – In Theory

While PLA is technically compostable, it requires industrial composting conditions-high temperatures and humidity levels not found in backyard setups or even most municipal composting facilities. As a result, PLA often ends up in landfills, where it degrades just as slowly as traditional plastics.

2. Low-Cost DIY Reuse

YouTube is full of creative makers melting PLA scraps with basic kitchen tools, then pouring them into silicone or metal molds. These projects usually result in:

- Decorative ornaments

- Coasters or bowls (non-food safe)

- Keychains and mini sculptures

It’s a fun and artistic way to repurpose small quantities, but not practical for large-scale recycling.

3. Home Filament Recycling

Some enthusiasts go a step further-turning scraps back into usable filament. To do this, they need:

- Shredder (to chop waste)

- Extruder (to melt and form filament)

- Winder (to spool it neatly)

Brands like Filabot, 3devo, and Wellzoom sell these systems ranging from $1,200 to $90,000+. Alternatively, makers can build DIY setups for $300+ using open-source designs from creators like Maker’s Muse, Dr. D-Flo, and CNC Kitchen. But beware-dust, fumes, and inconsistent quality are all real challenges.

4. School Labs & Precious Plastics Hubs

Some universities and local organizations participate in the Precious Plastics initiative, which promotes grassroots recycling. These labs often:

- Accept outside plastic contributions

- Offer access to pro-grade recycling tools

- Charge a small usage fee

If you’re a student or near a participating hub, this is a smart place to start.

5. Commercial Recycling Programs

A few companies offer mail-in programs. Here’s how they work:

- You ship your PLA waste (often costing $100+).

- In return, you receive store credit or discounts.

- Some also run recycling drives in collaboration with schools or makerspaces.

Notable names: Printerior, TerraCycle

Creative Ways to Repurpose Scraps

When traditional recycling isn’t feasible, creativity fills the gap. Here are some fun, practical, and aesthetic reuse ideas from makers:

- Pack scraps in glass jars for display or as lamp fillers

- Embed colorful pieces into translucent prints as decorative insets

- Use tree supports for aquascaping or miniature architecture

- Hang mini prints or jewelry from tree supports as display stands

- Stick supports into flower pots to hold up plants

- Layer scraps at the bottom of planters to improve drainage

- Melt and mold into dice, spinning tops, or custom seals

- Fill a toy mortar as ammo, or use scraps as packing material

- Turn print fails into incense holders with just a drill

Final Thoughts

While recycling 3D printing scraps remains a challenge, it’s also an opportunity to rethink what we call “waste.” Whether you’re crafting jewelry from tree supports or investing in a home extrusion setup, every bit of reuse helps reduce your environmental impact—and might even spark your next creative project.

Have scraps piling up? Maybe it’s time to give them a second life—one layer at a time.

👉 From an environmental perspective, you can also choose FacFox’s 3D printing service.

Unlike many recycling companies that don’t work with individual hobbyists, our batch production model allows us to better sort and recycle material waste.