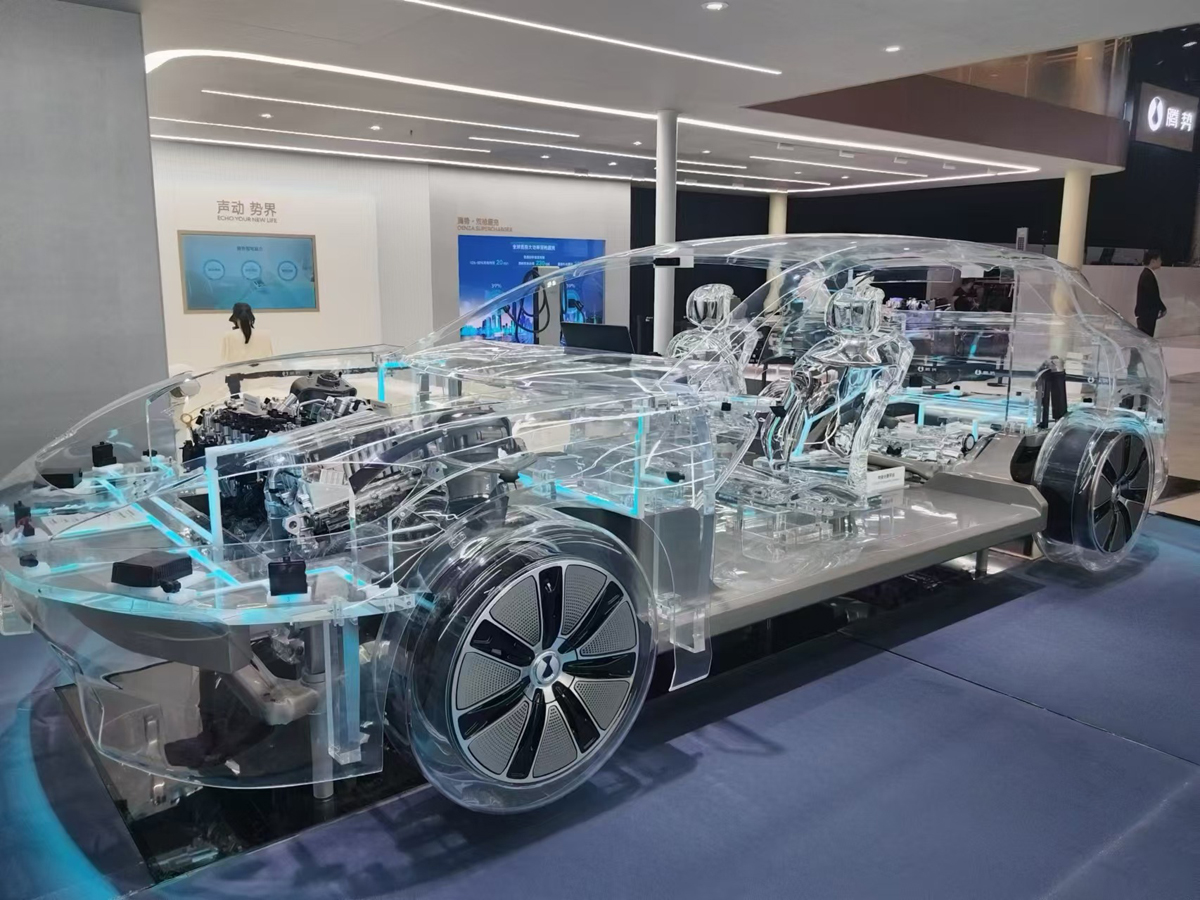

In the automotive industry, the right materials can define the look, feel, and performance of a vehicle. Among the most versatile and aesthetic materials is PMMA (Polymethyl Methacrylate)—commonly known as acrylic. With its exceptional clarity, high gloss, and weather resistance, PMMA plays a critical role in automotive prototyping and part production, especially in areas where transparency, translucency, and surface quality are essential.

At FacFox, we specialize in CNC machining of PMMA to help automotive designers and engineers bring high-precision concepts to life—quickly and cost-effectively.

PMMA Applications in the Automotive Industry

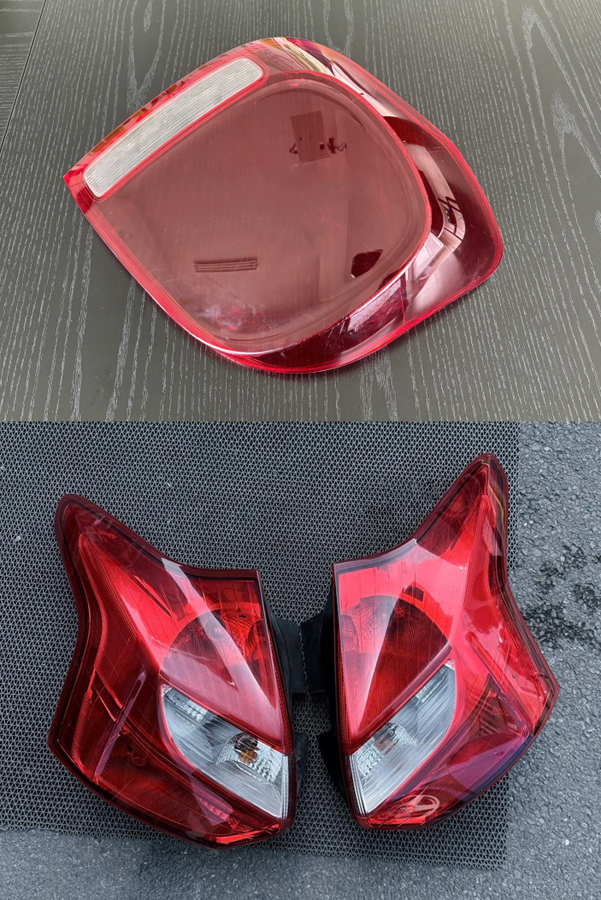

1. Taillight Prototypes

PMMA’s high light transmittance (92%), surface hardness, and excellent light-scattering properties make it the ideal material for taillight masks, reflectors, and light guides. Compared to PC (polycarbonate), PMMA is easier to machine, more cost-effective, and sufficiently durable for short-use, low-heat light components.

2. Dashboard Instrument Covers

Instrument panel masks must protect the gauges while maintaining crystal-clear visibility. PMMA provides optical clarity, dimensional stability, and resistance to heat from both the sun and engine, making it the top choice for dashboard cover prototyping.

3. Outer Pillars & Decorative Trim

For high-gloss finishes like piano black A/B/C pillars, PMMA combined with ABS or used in a toughened grade delivers UV stability, scratch resistance, and impact performance—all without the need for paint. This eco-friendly, cost-effective alternative to painted ABS is rapidly becoming a mainstream solution.

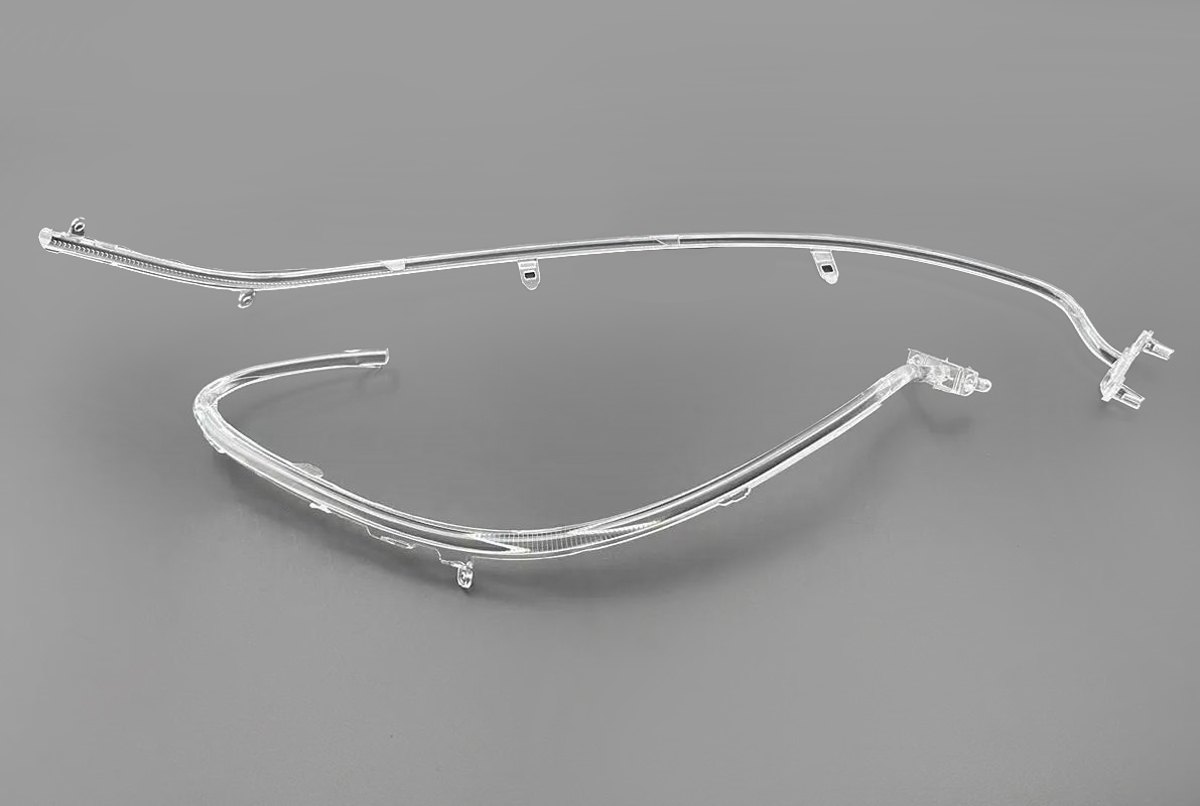

4. Interior Lighting Prototypes

Reading lights and ambient lighting strips often rely on matte or frosted PMMA to achieve soft diffusion and uniform illumination. Rigid light guides made with PMMA offer sleek integration with automotive interiors, enhancing both functionality and ambiance.

5. Rearview Mirror Housings

High-gloss, impact-resistant, and UV-stable—toughened PMMA is increasingly used in mirror housing prototypes to replace ABS+paint systems, reducing process steps and eliminating VOC emissions, while meeting mechanical test standards like drop tests.

Why Choose FacFox for PMMA CNC Machining?

At FacFox, we combine state-of-the-art 5-axis CNC machining with deep expertise in PMMA processing to produce visually striking and dimensionally accurate prototypes for automotive clients around the globe.

- High transparency and surface polish

- Custom matte, frosted, or optical-grade finishes

- Precision machining for tight tolerances

- Quick lead times and global shipping

- No minimum order quantity

Whether you’re developing functional prototypes, visual models, or small-batch production parts, FacFox delivers clarity, performance, and consistency—at any scale.

Drive Your Designs Forward

Bring your automotive innovations to life with FacFox’s PMMA CNC machining services. From taillights to dashboards, from lighting systems to trim—we machine clarity into every detail.

👉 Get an instant quote at FacFox.com

📩 Need guidance on material selection or finish options? Our team is ready to help.

FacFox – Your On-Demand Partner for Transparent Excellence in Automotive Prototyping