Osteoporosis, the “silent killer” affecting a staggering 200 million individuals globally (primarily women) and causing a fracture every 3 seconds, represents a significant unmet medical need. The sheer economic burden of these fractures, reaching a staggering $48 billion annually in the US, Canada, and the EU alone, underscores the urgent demand for more effective treatments.

Now, a groundbreaking innovation published in the April 2025 issue of Advanced Healthcare Materials offers a beacon of hope. A collaborative research team from Wuhan Union Hospital (Huazhong University of Science and Technology) and Dalian University of Technology has achieved a significant breakthrough: successfully activating the “neural repair switch” of bone tissue using 3D printed degradable metal scaffolds in conjunction with ultrasound technology, leading to effective bone regeneration.

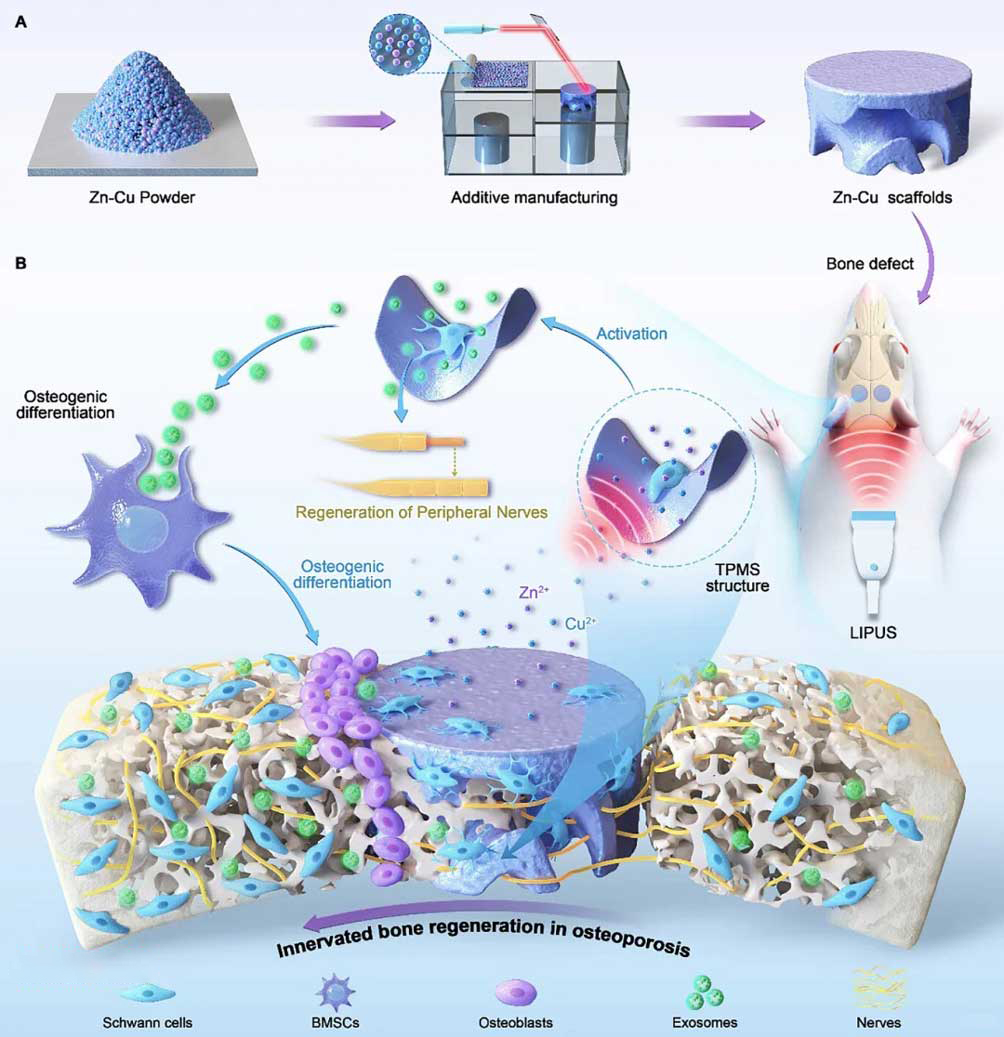

This research provides a comprehensive blueprint for a novel treatment approach, centered around an ultrasound-driven 3D printed scaffold that promotes innervated bone regeneration. Let’s delve into the key aspects of this exciting development:

The Innovation

- Intelligent 3D Printed Scaffold: Utilizing a zinc-copper alloy, the scaffold boasts controllable degradability and the release of beneficial ions.

- Manufacturing Process: Employing metal 3D printing technology allows for customized production based on individual patient bone defects, with the potential for mass production.

- Ultrasound-Assisted Therapy: Leveraging FDA-approved ultrasound equipment minimizes regulatory hurdles and allows for simple, outpatient treatment, potentially reducing medical costs.

The Mechanism

The core of this innovation lies in its ability to reconstruct the bone’s neural communication network.

- The 3D printed scaffold provides an ideal microenvironment and facilitates the sustained release of active factors.

- Ultrasound acts as a catalyst, activating key repair cells and promoting intercellular signal transmission, creating a synergistic effect.

- This combined approach effectively activates the bone tissue’s endogenous repair mechanisms.

Addressing a Critical Market Pain Point

Traditional osteoporosis treatments often fall short because they primarily focus on calcium loss and bone density, neglecting the crucial role of the nervous system in bone health. This study highlights that bones are not just structural; they are dynamic systems intricately controlled by neural networks. In osteoporosis, this control system is impaired, particularly the reduction of neural auxiliary cells vital for repair. Animal model data clearly demonstrated the correlation between a decrease in these cells and a decline in bone repair capabilities.

The Innovative Solution: A 3D Printing “Golden Combination”

The research team’s solution tackles this unmet need by combining the structural support of a precision 3D printed scaffold with the activating power of ultrasound. This creates a “smart” medical device capable of both supporting bone and stimulating its repair.

Key Breakthroughs in 3D Printing

This research moves beyond passive support, utilizing metal 3D printing (selective laser melting) for functional manufacturing. The innovative scaffold design includes:

- Intelligent Cavity Structure: An upper layer forms a closed cell culture chamber, providing an optimal environment for repair cells.

- Bionic Network Interior: A honeycomb-like structure offers both robust support and an ideal surface for cell growth.

- Strategic Material Selection: The use of a zinc-copper alloy allows for gradual degradation and the release of beneficial metal ions, transforming the scaffold into a “bioreactor” that actively participates in the healing process.

The Synergistic Power of Ultrasound

Combining the 3D printed scaffold with readily available ultrasound technology creates a powerful synergistic effect:

- Ultrasound-induced micro-vibrations in the scaffold activate key repair cells.

- Ultrasound modulates the release rate of metal ions from the scaffold, ensuring a sustained therapeutic effect.

- Experimental data showed that this combination significantly increased the activity of key repair cells and nearly doubled the efficiency of intercellular signal transmission.

Commercial Value: Repairing the “Neural Communication Network”

The study’s most significant commercial potential lies in its ability to repair the fundamental communication network within bone tissue. Healthy bone repair relies on signals transmitted between cells. In osteoporosis, this “communication network” is disrupted. This research demonstrates that the 3D printed scaffold and ultrasound combination can rebuild this network, restoring the bone’s natural self-repair capabilities. Experimental data confirmed a significant increase in the migration ability of bone repair cells and the expression of key repair factors under this combined treatment.

Market Verification: Impressive Efficacy Data

Animal model studies yielded remarkable results:

- At 2 weeks, the group treated with the 3D printed zinc-copper stents and ultrasound showed over 3 times more new bone formation compared to the control group.

- By 6 weeks, the bone defect was almost completely closed, with a repair rate of nearly 90%.

- The therapy achieved dual repair of both bone and nerve tissue, with a significant increase in key repair cells and nerve fiber density.

- Safety data indicated a controllable scaffold degradation process without systemic inflammation or organ damage.

Market Prospects and Investment Value

The researchers emphasize the platform potential of this technology. By adjusting 3D printing parameters and material composition, this approach can be expanded to treat a wide range of orthopedic conditions, from traumatic bone injuries to bone tumors.

Dr. Smith, a bone regeneration expert at Harvard University, lauded the study for its clever integration of biomaterials, ultrasonic engineering, and neuroscience, highlighting the crucial role of neural regulation in bone regeneration and its potential to revolutionize orthopedic treatment.

This research signifies a fundamental shift in the application of 3D printing in medicine – moving beyond a manufacturing tool to a core component of a comprehensive treatment platform. By synergizing with existing technologies like ultrasound, this innovation inspires a new perspective on medical devices: not just replacing function, but actively awakening the body’s innate capacity for self-healing. This breakthrough holds immense promise for the millions suffering from osteoporosis and other bone-related conditions, offering a glimpse into a future of more effective and less invasive treatments.

This groundbreaking research underscores the transformative potential of metal 3D printing in revolutionizing healthcare. At FacFox, we are at the forefront of metal 3D printing services, offering state-of-the-art technology and expertise to bring innovative designs like these intelligent bone scaffolds to life. From biocompatible materials to intricate geometries and customized solutions, FacFox is your trusted partner in accelerating medical device development and manufacturing. Ready to explore the possibilities of metal 3D printing for your next medical breakthrough? Visit FacFox today and let’s build a healthier future together.