A recent paper titled “Thick-panel origami structures forming seamless surfaces”, published in Nature Communications by researchers from the National University of Singapore and the University of Delaware, reveals a revolutionary leap in structural design—one that seamlessly merges the elegance of ancient origami with the precision of 3D printing. The result? Deployable structures with smooth, continuous surfaces, opening doors to futuristic applications from foldable buildings to space telescopes.

The Origami Engineering Dilemma: Thickness Matters

Origami’s charm lies in its geometric transformation. But in engineering, using real materials with thickness introduces a major issue: traditional folds create gaps and uneven surfaces, which are problematic in watertight, airtight, or high-precision applications like antennas or solar panels.

As seen in conventional thick-panel origami, surface discontinuities (grooves and protrusions) prevent seamlessness—critical flaws for structural and functional integrity.

The Breakthrough: Seamless Folding by Design

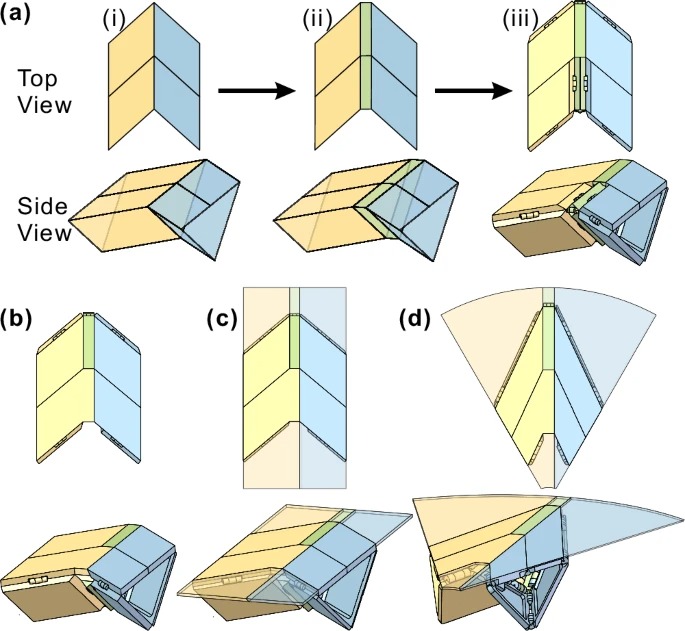

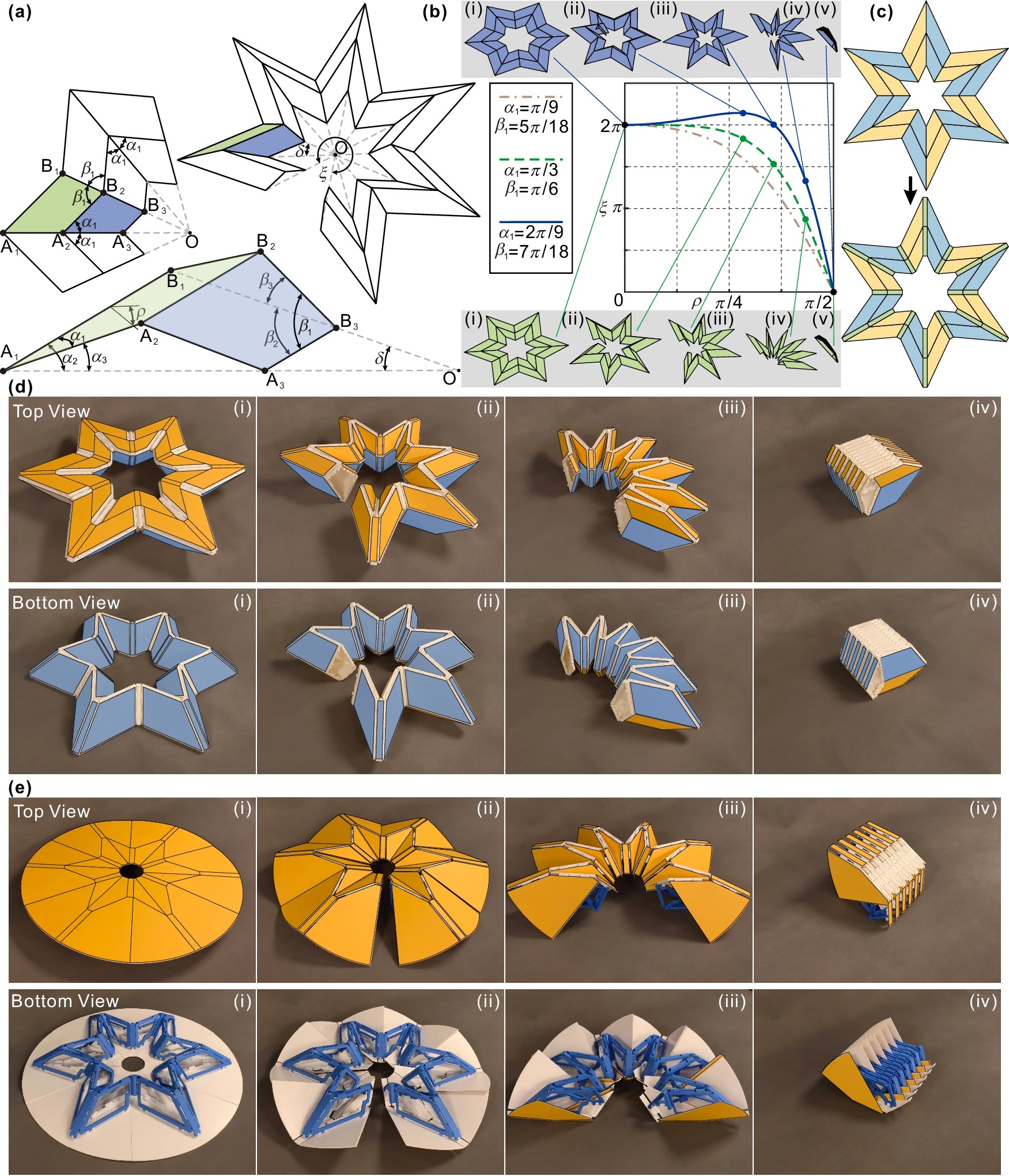

The team tackled this by rethinking the fold itself. By extending adjacent panels around “valley” and “mountain” folds and eliminating interfering grooves, they achieved flat, continuous surfaces. This design principle was supported by deep geometric and kinematic analysis—resulting in an optimized folding strategy that maintains mobility and surface integrity.

From Digital to Physical: 3D Printing Realizations

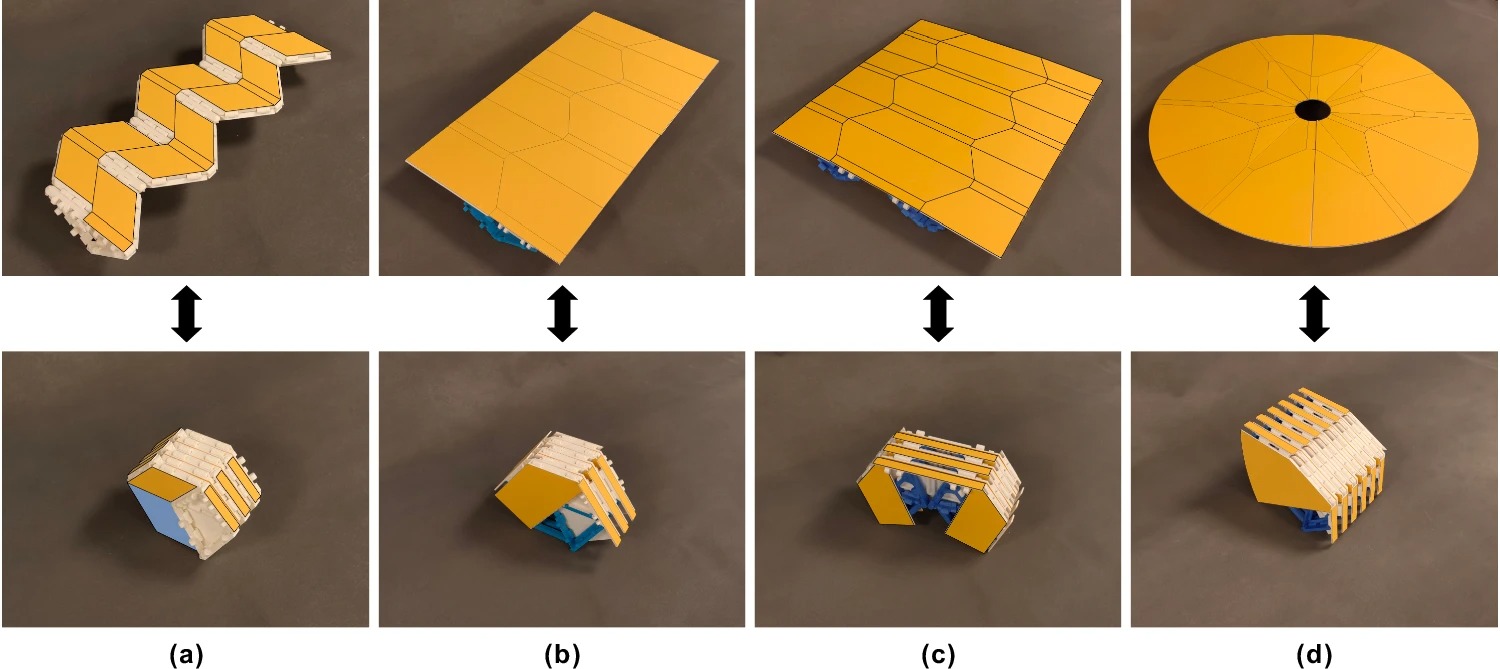

Turning theory into reality, the researchers 3D printed various prototypes using PLA material and FDM printers (Bambulab X1C and Raise3D Pro3). These models featured integrally printed swivel joints, steel pins for strength, and colored films to highlight the seamless surfaces.

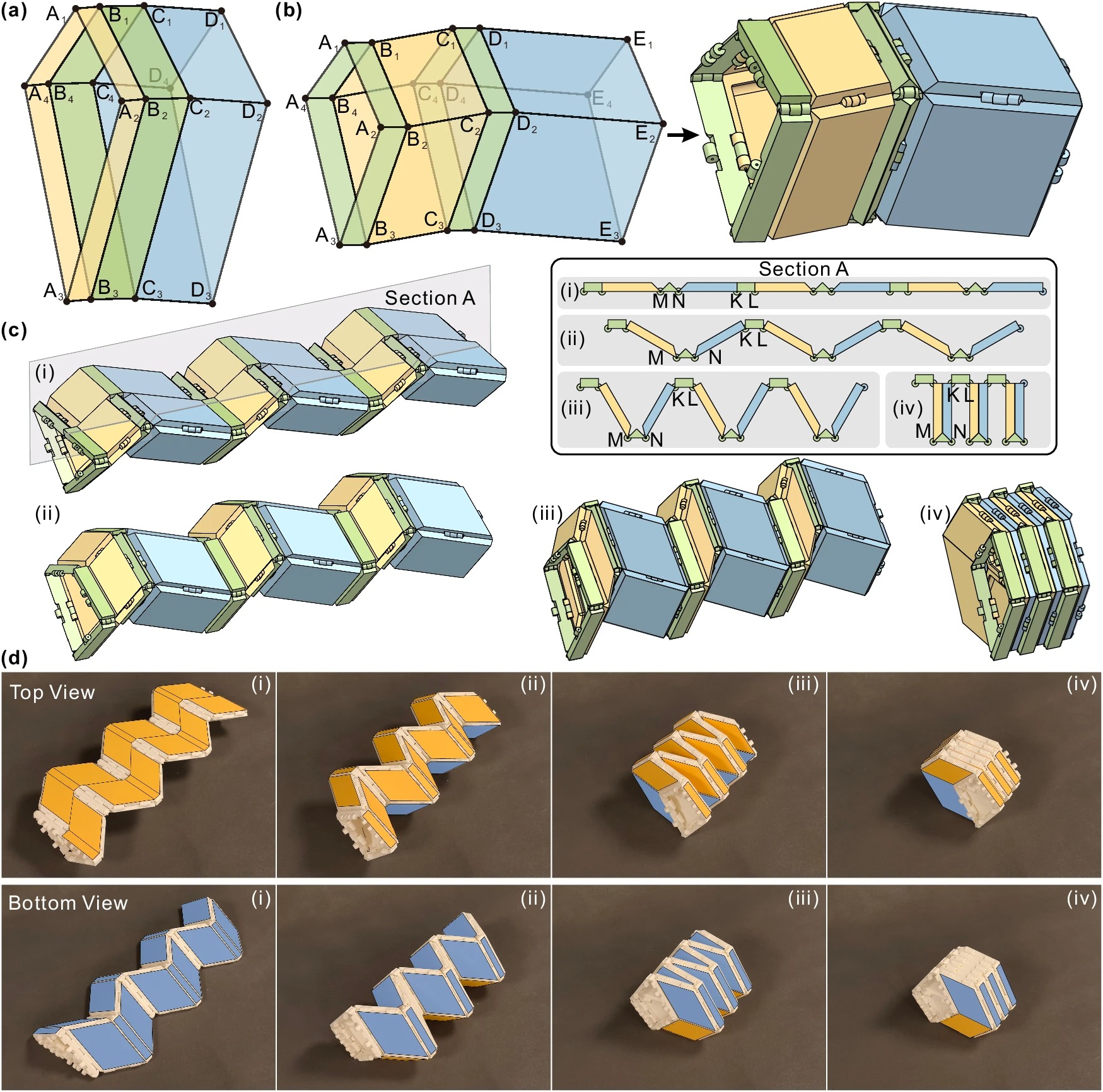

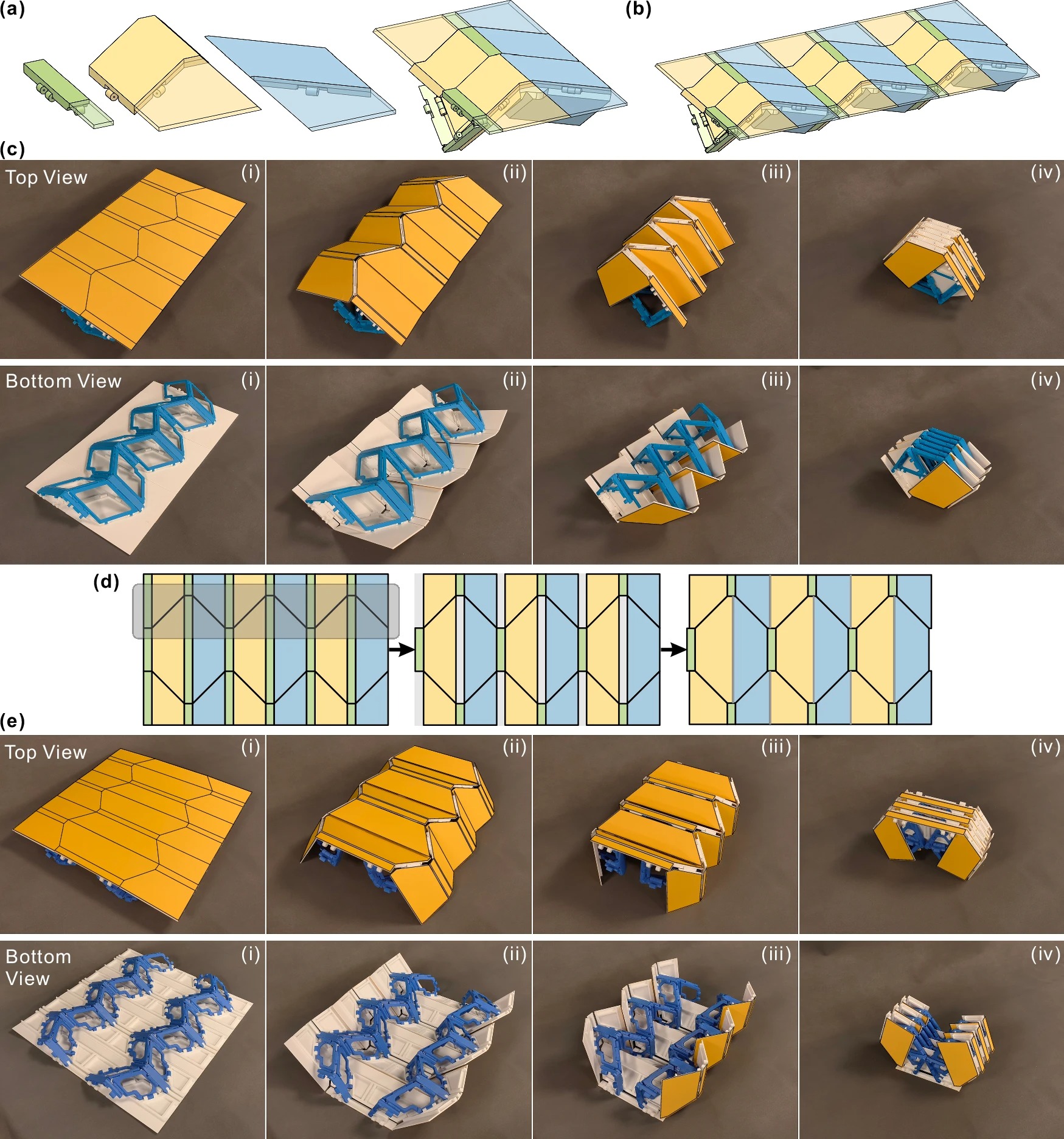

Notably, the improved origami units were tested across multiple shapes and configurations—from flat panels to curved trajectories. Each design demonstrated scalability and versatility.

The modified structure refines the original model by extending panel shapes while keeping joint positions unchanged to maintain motion, resulting in a more application-ready surface. Its tessellation pattern optimizes structural efficiency, creating a deployable unit with improved stability.

A 3D-printed model demonstrates the seamless integration of a yellow top layer for smooth deployment and blue bottom panels for support. The symmetric tessellation further enhances fold-deploy performance, ensuring practical usability.

A final 3D-printed version showcases the complete tessellated structure, reinforcing both functionality and aesthetic cohesion, as demonstrated in the attached video.

Design Innovations: Panel Minimization and Symmetric Inlay

To further improve efficiency, the team introduced:

-

Panel minimization: Reducing top-panel count from 18 to 12 while preserving functionality.

-

Symmetrical inlay: Creating larger deployable structures by embedding modular units, increasing both strength and surface area without sacrificing compactness.

These steps made the designs lighter, simpler to manufacture, and better suited for real-world deployment.

Unlocking the Future: Applications and Possibilities

This origami-3D printing fusion is more than an academic feat—it lays the groundwork for:

-

Deployable architecture: Rapid-deployment shelters, pop-up stages, foldable pavilions.

-

Space tech: Seamless antennas, solar arrays, or telescope reflectors.

-

Everyday utility: Folding furniture, camping gear, sunshades, and even consumer electronics like multi-fold phones or transforming robots.

As materials and printing technologies advance, the potential applications expand—from medical devices and disaster relief to aerospace exploration and smart consumer gadgets.

Final Thoughts

This research showcases more than a novel structure—it’s a vision of engineering’s future. By blending the centuries-old wisdom of origami with the cutting-edge capabilities of 3D printing, we’re entering a world where shape, function, and fabrication converge.

Origami is no longer just art—it’s engineering.

3D printing is no longer just a tool—it’s transformation.

Let the folds unfold the future.

Source: Thick-panel origami structures forming seamless surfaces | Nature Communications