A recent breakthrough at the Oak Ridge National Laboratory (ORNL) has caused a stir in the additive manufacturing (AM) community. Researchers there have successfully 3D printed the first batch of tungsten parts with complex geometries and, they say, no defects. This achievement is a major step forward for the development of clean energy technologies like nuclear fusion reactors.

FacFox is a leading provider of metal 3D printing services, including tungsten. In this article, we will explore the challenges and opportunities of 3D printing tungsten.

Why is 3D Printing Tungsten a Challenge?

Tungsten is prized for its incredibly high melting point, making it ideal for parts that will be exposed to extreme heat. However, this same property also makes it difficult to work with using traditional manufacturing methods. Tungsten is brittle at room temperature, and conventional techniques can struggle to produce complex shapes without introducing cracks or imperfections.

New Techniques for Promising Results

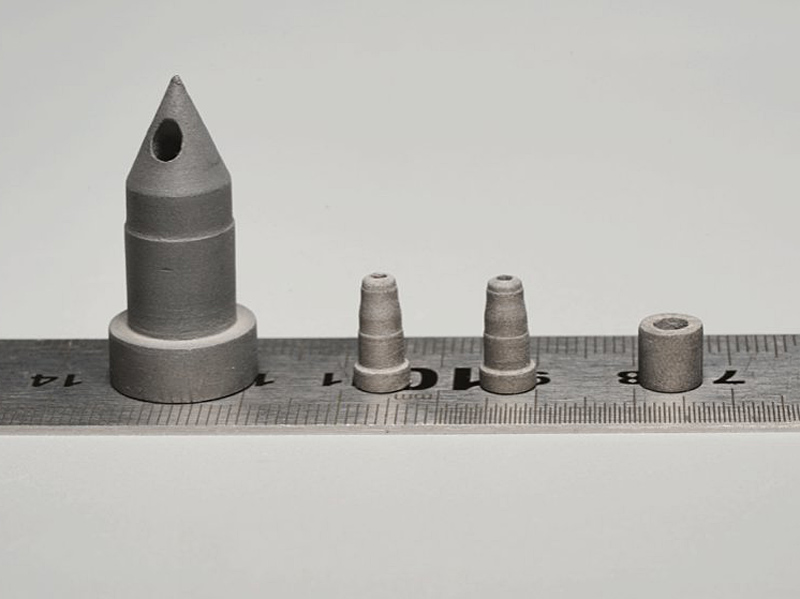

ORNL’s success hinges on their use of electron beam powder bed fusion (EB-PBF) additive manufacturing. This technique uses a high-powered electron beam to melt tungsten powder layer by layer in a vacuum, minimizing impurities and residual stress. The result is complex tungsten parts with the potential to be defect-free.

Applications for 3D Printed Tungsten

The ability to 3D print complex tungsten parts opens doors for a variety of applications:

- Medical and Nuclear Industries: Tungsten’s ability to shield radiation makes it ideal for medical equipment and nuclear power plants.

- Ultra-High Temperature Environments: Parts for machines like nuclear fusion reactors can benefit from tungsten’s ability to withstand extreme heat.

- Electrical and Mechanical Systems: Tungsten’s properties make it valuable for electrical contacts and high-density counterweights.

- Aerospace: Tungsten’s heat resistance makes it useful for components like nozzles and heat shields.

- Machining: Tungsten carbide tools can be 3D printed for cutting and shaping other hard materials.

The Future of 3D Printed Tungsten

ORNL’s breakthrough paves the way for wider adoption of 3D-printed tungsten in various industries. With its potential to revolutionize clean energy and other fields, 3D printed tungsten is definitely a technology to watch.

FacFox: Your Partner in Metal 3D Printing

While FacFox doesn’t currently offer 3D printing for tungsten specifically, we are on the cutting edge of metal 3D printing technology. We offer a wide range of materials and can help you find the perfect solution for your project. If you’re interested in learning more about 3D printing for complex, high-temperature parts, contact FacFox via info@facfox.com today.