This article explores common challenges in CNC machining, such as excessive clamping time, material waste, and lengthy processing hours, and how to address them through cost-effective design practices.

Shifting Mindset: From “Customer First” to Cost-Conscious Design

Many engineers prioritize customer needs above all else, leaving cost considerations to the manufacturing department. However, this approach can be detrimental. Here’s why:

- Product Cost is Paramount: Integrated Product Development (IPD) emphasizes product development as an investment. If production costs are high, the product may not generate profit, rendering the development a waste of resources.

- Design Drives Cost: Over 85% of product cost is determined during the design phase. The remaining 15% comes from manufacturing. Implementing cost-oriented design from the outset is crucial.

Understanding CNC Cost Drivers

To effectively reduce costs, we need to understand the factors that influence them:

- Processing Time: The longer it takes to machine a part, the higher the cost. Machining time is the biggest cost driver in CNC.

- Material Cost: The cost of the raw material blank significantly impacts the final price. Optimized design can minimize waste by using standardized blanks.

- Setup Time: For small batches, setting up the CNC machine and programming the toolpath can be a significant cost factor. Mass production helps spread this fixed cost over more parts.

- Design Complexity: Special requirements like tight tolerances, thin walls, and complex features necessitate specialized tools, slower processing speeds, and more machining steps, all of which raise costs.

Cost-Reduction Design Techniques

By considering these cost drivers, we can implement design strategies to minimize CNC machining expenses:

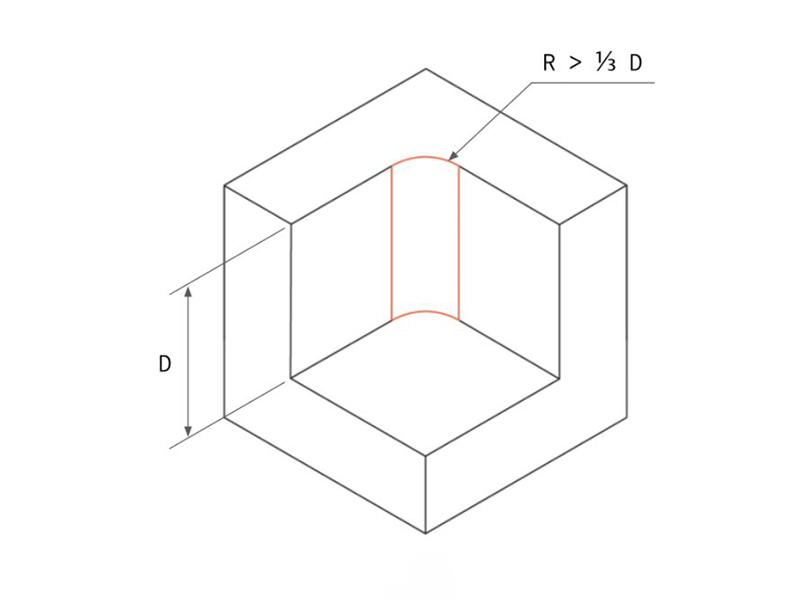

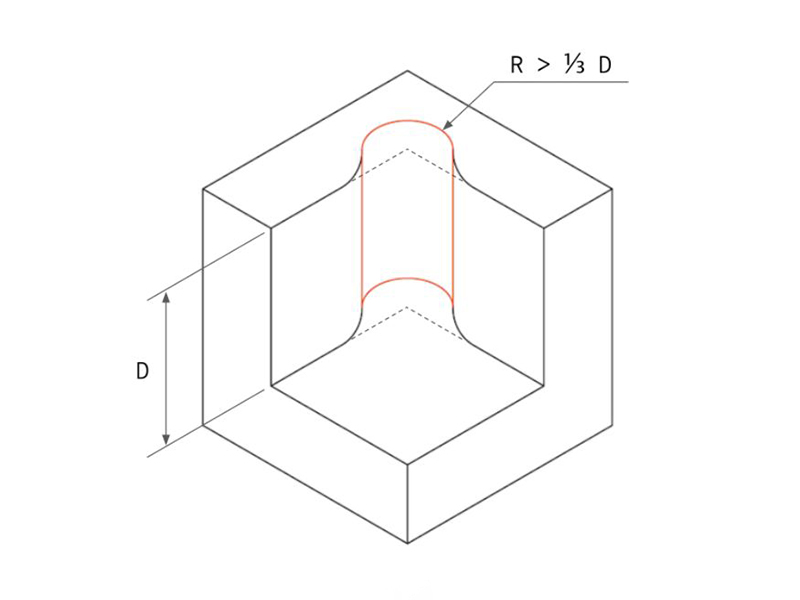

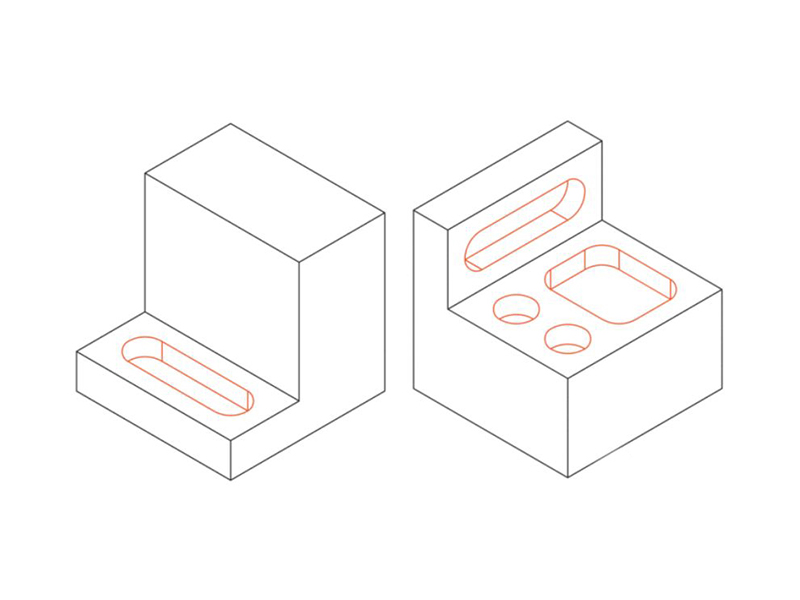

1. Rounding Internal Corners

CNC tools are cylindrical. When machining pockets, sharp internal corners will result in a rounded fillet with the same radius as the tool. To reduce costs:

- Design fillets with a minimum size of one-third the pocket depth (larger is better).

- Maintain consistent fillet size throughout the part for efficient tool usage.

- Consider a smaller fillet (0.5mm or 1mm) at the pocket floor or do not use a fillet.

- The ideal fillet size should be slightly larger than the tool radius to minimize tool stress and processing time.

- When cooperating fillet with cubic blacnk, you can design as below:

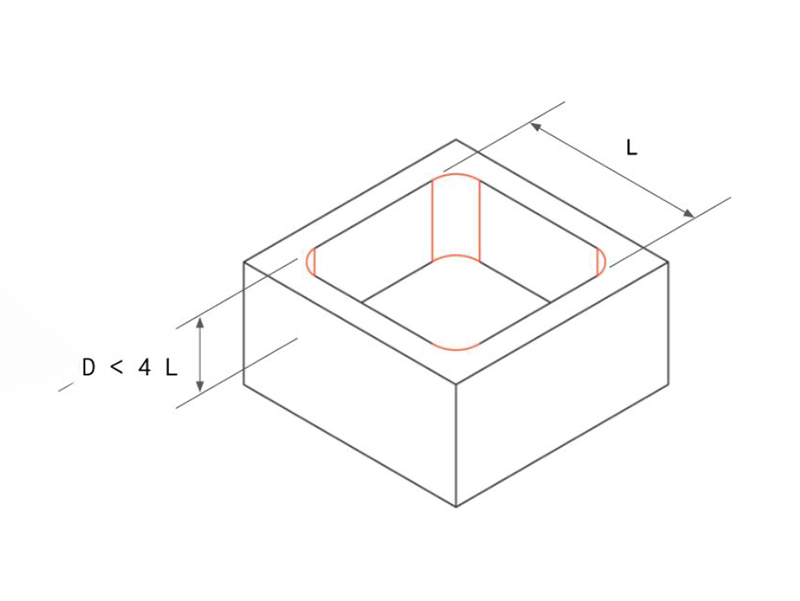

2. Reduce Pocket Depth

Deep pockets require more material removal, significantly increasing processing time. CNC tools have limitations on depth. Optimal performance is achieved when the pocket depth is 2-3 times the tool diameter. While deeper pockets can be machined (up to 4 times the diameter), it significantly increases costs, especially for multi-axis machines.

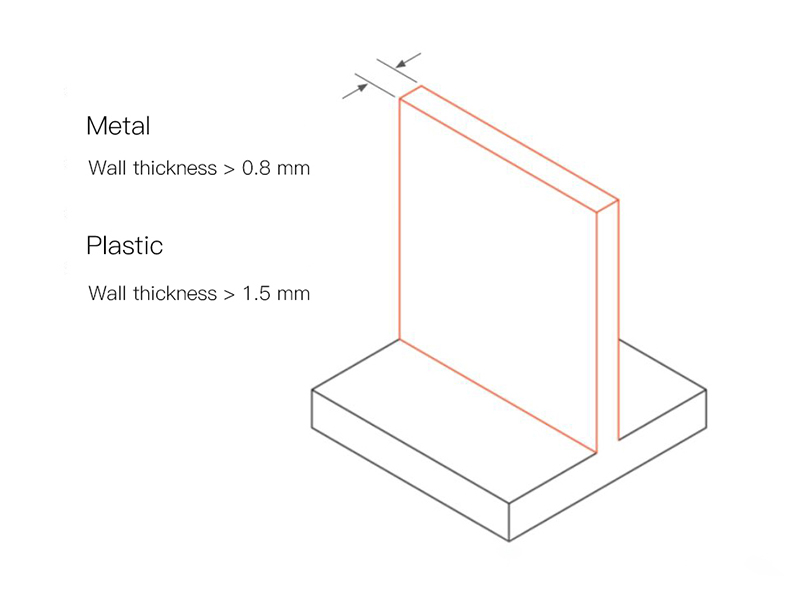

3. Avoid Thin Walls

Thin walls are generally discouraged as they are weak and expensive to machine. They are prone to deformation and require complex toolpaths, slowing down the process. Additionally, thin walls are more susceptible to vibration, making high-precision machining challenging. Here’s how to avoid them:

- For metal parts, aim for a minimum wall thickness of 0.8mm (thicker is better).

- For plastic parts, aim for a minimum wall thickness of 1.5mm (thicker is better).

- A minimum of 0.5mm for metal and 1mm for plastic is possible but not recommended.

- Pay close attention to design features like holes and slots around edges, as these can create thin walls.

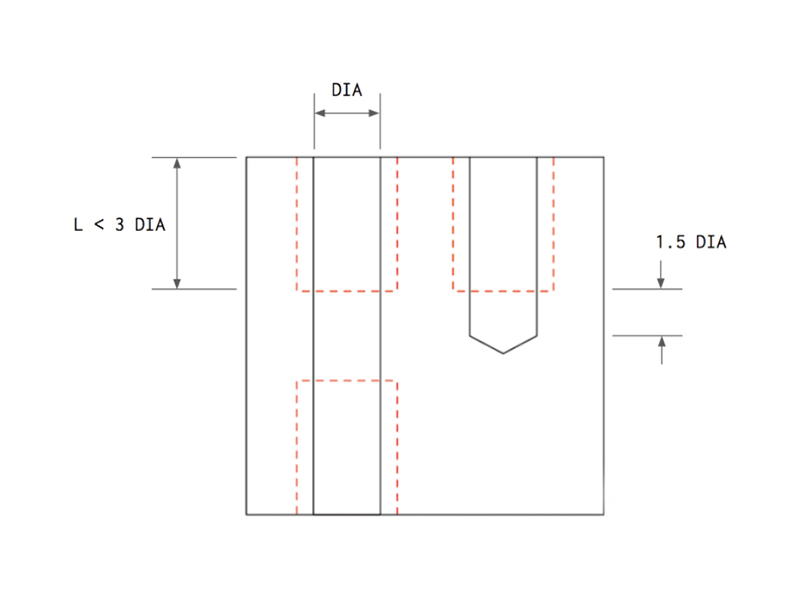

4. Reduce Thread Depth

Unnecessary thread depth increases costs due to the need for specialized tooling. Remember, excessive thread depth (more than 3 times the hole diameter) does not enhance connection strength. To minimize costs:

- Limit thread depth to a maximum of 3 times the screw hole diameter.

- For blind hole tapping, incorporate at least half the screw diameter’s extra length at the hole’s root.

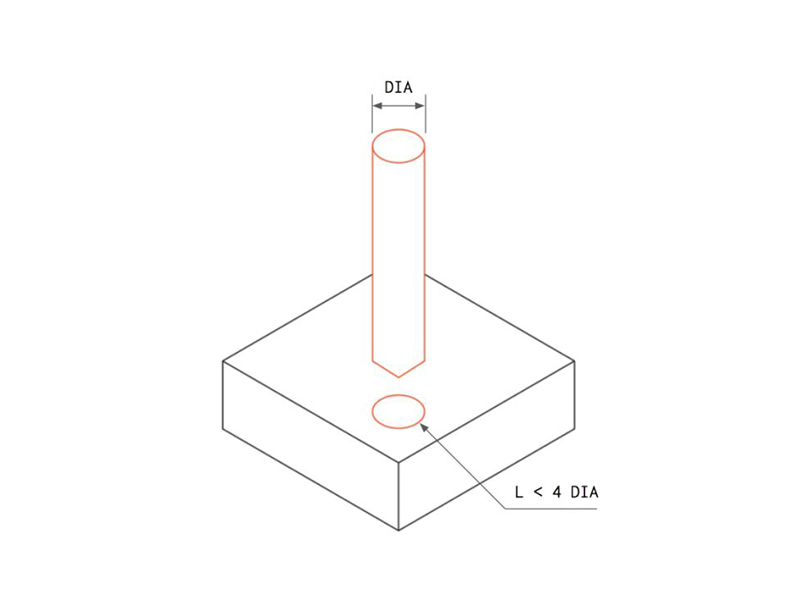

5. Standardize Hole Sizes

Standard drill bits enable fast and precise hole creation. Non-standard holes necessitate end mills, which can be more expensive. Additionally, limit hole depth to a maximum of 4 times the diameter. While deeper holes are possible (up to 10 times the diameter), machining becomes significantly more complex and costly.

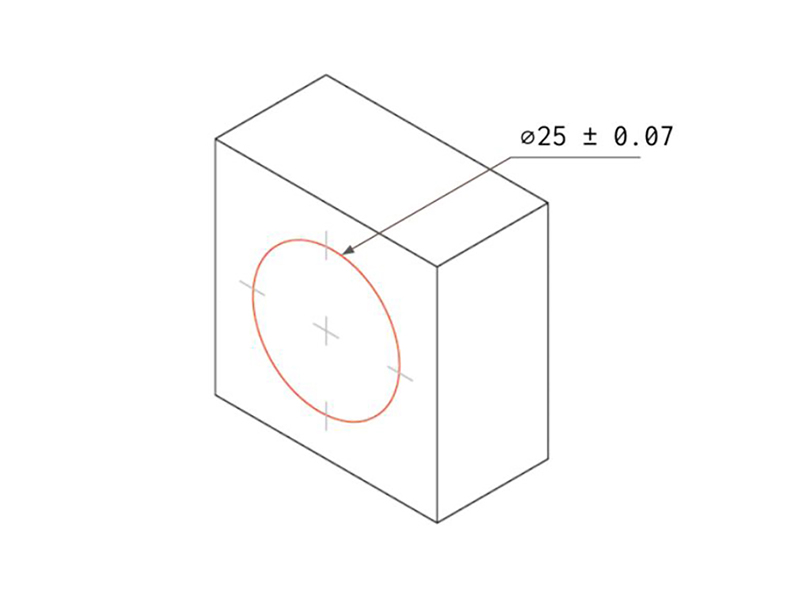

6. Minimize Tolerance Requirements

Tight tolerances necessitate intricate machining processes, extending processing time and requiring additional inspections. Here’s how to optimize tolerance usage:

- Define tolerances only when necessary. Avoid marking tolerances on every dimension.

- Utilize standard tolerances (±0.2mm or looser) for non-critical dimensions, significantly reducing processing costs.

- Tight tolerances for internal features are challenging to guarantee. Forces during machining can cause small defects like burrs on edges. These require manual inspection and deburring, adding to labor costs.

7. Reduce Clamping Times

Ideally, a part should only require one clamping. For instance, a part with blind holes on both sides might need to be clamped twice: once for each side. This can be avoided by:

- Repositioning the part after machining one side to complete the other side without requiring another clamp.

- Consider dividing complex parts into multiple components for separate CNC machining, then fastening them together using techniques like threading or welding.

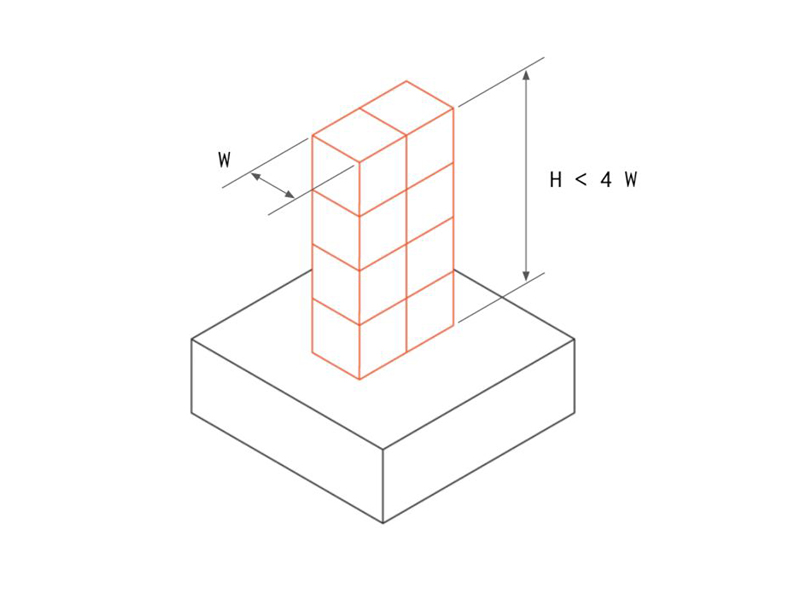

8. Avoid Deep Features with High Aspect Ratios

Small features with a large aspect ratio (depth to width) are prone to vibration during CNC machining, making it difficult to achieve accuracy. To address this:

- Design these features to connect with thicker walls or incorporate support structures like stiffeners.

- Avoid designing features with an aspect ratio exceeding 4.

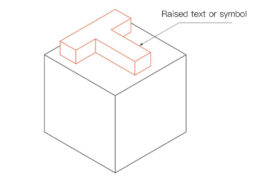

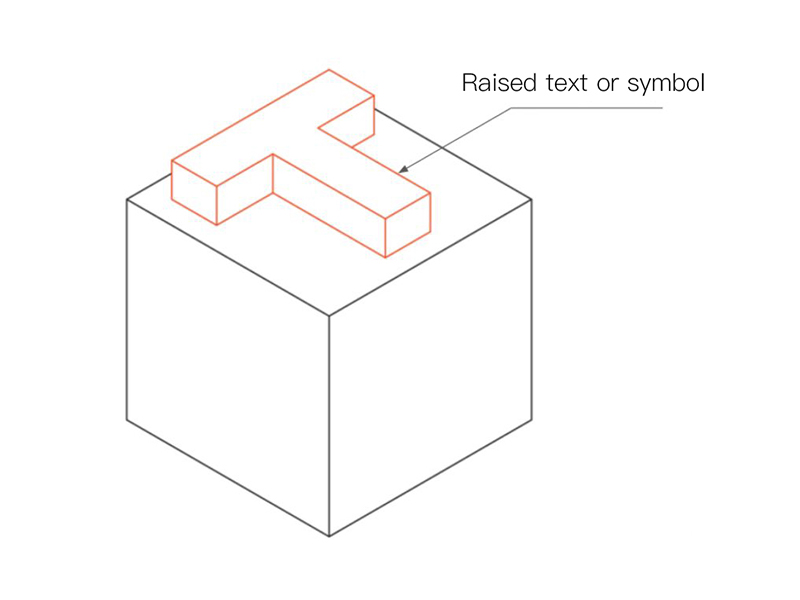

9. Eliminate Text and Symbols on Surfaces

Machining text and symbols directly onto parts significantly increases costs due to additional machining steps and processing time. Consider these alternatives:

- Utilize post-processing techniques like silk-screening or spray painting to add text and symbols at a lower cost.

- If text or symbols are unavoidable, opt for concave markings instead of raised ones, as the latter require removing more material.

10. Consider Material Machinability

The ease with which a material can be machined significantly impacts processing costs. Here’s a general guideline:

- Easier to machine materials (higher machinability) result in faster processing and lower costs.

- Softer and more ductile materials are generally easier to machine.

- Examples of good machinability materials include:

- Brass C360 (excellent machinability)

- Aluminum alloys (Aluminum 6061 and 7075)

- Steel has lower machinability compared to aluminum, requiring longer processing times. However, there are variations within steel itself.

- Stainless steel 304 has a machinability index of 45%.

- Stainless steel 303 has a machinability index of 78%, making it easier to process.

- Machinability of plastics depends on stiffness and thermal properties. Plastics can melt and deform under high processing temperatures.

- POM is one of the easiest plastics to machine with CNC.

- ABS is another relatively machinable plastic.

- PEEK and nylon are common engineering plastics that are more challenging to machine.

11. Choose Cost-Effective Raw Materials

The price of raw material blanks is another crucial factor influencing CNC costs. Here are some considerations:

- Aluminum 6061 is a cost-effective material with good machinability, making it ideal for prototypes.

- Stainless steel 303 and brass C360 also offer good machinability, but their high blank prices make them more suitable for mass production where the high cost is offset by larger batch sizes.

- While the cost of some plastics like ABS, nylon, and POM is comparable to aluminum 6061, they are generally more difficult to machine.

- PEEK is a very expensive material and should only be used when absolutely necessary.

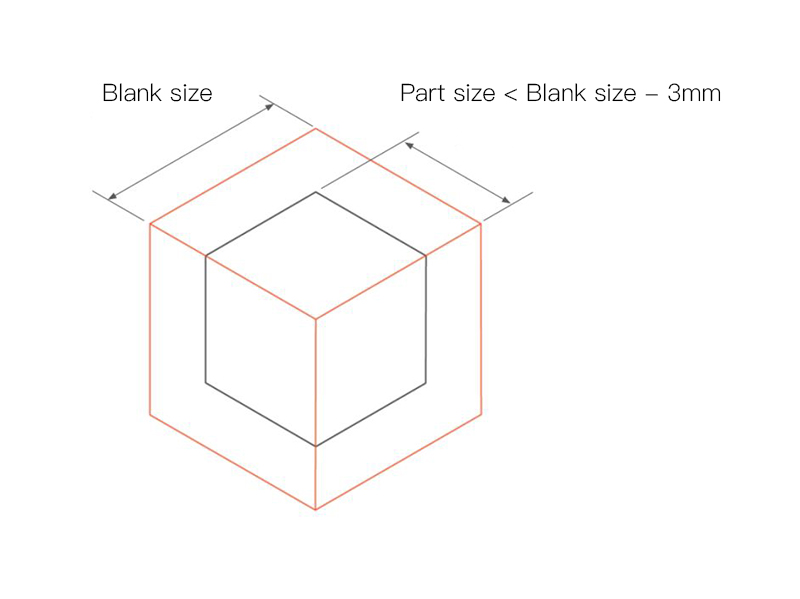

12. Minimize Blank Size

Blank size also affects CNC costs. Material needs to be removed from all sides of a part to ensure dimensional accuracy, which can lead to significant material waste, especiall y for large batches. Here’s how to optimize blank size:

- Generally, the blank size should be at least 3mm larger than the finished part size on all sides.

- Consult with suppliers regarding standard blank size specifications. Designing parts close to these standard sizes can help reduce material waste.

13. Limit Surface Treatments

While surface treatments enhance the aesthetics and functionality of CNC parts by protecting them from harsh environments, they also add to the cost. Multiple surface treatments further increase costs due to additional processing steps and masking requirements. Here’s how to minimiz e costs:

- Eliminate unnecessary surface treatments.

- Avoid using multiple surface treatments on the same part.

14. Leverage Mass Production

Batch size significantly impacts CNC machining costs. Smaller batches incur a higher initial setup cost per part compared to larger batches where the setup cost is spread across more parts.

15. Design Axially Symmetrical Parts

Axially symmetrical parts can be machined using lathes or milling machines with lower hourly rates compared to 3 or 5-axis machining centers.

16. Explore Alternative Manufacturing Processes

CNC machining is not always the most cost-effective option, especially for small batches. Consider these alternatives:

- 3D printing can be more economical for small batches.

- For larger quantities, molding processes like investment casting and injection molding might be more cost-effective.

Conclusion

By implementing these cost-reduction design techniques, you can significantly minimize CNC machining expenses. Remember, cost-conscious design should be an integral part of the product development process from the very beginning. This collaborative approach between engineers and manufacturing teams ensures that both functionality and affordability are considered throughout the product lifecycle.

Additional Tips:

- Design for Manufacturability (DFM): DFM is a systematic approach that analyzes how a product can be easily and economically manufactured. By incorporating DFM principles early in the design phase, potential issues can be identified and addressed before they become costly problems during production.

- Collaboration is Key: Open communication between design engineers and manufacturing professionals is crucial for cost-effective CNC machining. Engineers can benefit from the expertise of manufacturing personnel who understand the capabilities and limitations of CNC machines and can suggest alternative designs or materials to reduce costs.

- CNC Machining Quotations: Obtaining quotes from multiple CNC machining service providers allows for cost comparisons and helps identify the most cost-effective option for your project.

Turn your designs into reality with FacFox’s exceptional CNC machining services! At FacFox, we understand the importance of balancing design intent with cost-effectiveness.

Our team of experienced engineers can collaborate with you throughout the design process to identify opportunities for cost reduction while maintaining the integrity and functionality of your parts.

We leverage our extensive knowledge of CNC machining principles and access to state-of-the-art equipment to deliver high-quality parts that meet your exact specifications.

Additionally, our competitive pricing and efficient production processes ensure you receive the best value for your investment.

Ready to transform your designs into high-precision CNC machined parts? Contact FacFox today! Our engineers will work closely with you to find the optimal solution that meets your design requirements, budget constraints, and quality standards. Together, let’s turn your vision into a reality!