Electroplating is a metal finishing process that uses electricity to coat a part with a thin layer of metal. Electroplating can improve the properties of parts made by CNC milling and 3D printing, such as strength, durability, and appearance. Electroplating can also offer a variety of metal options, such as copper, zinc, nickel, etc.

In this article, we will explain how electroplating works, what are its advantages and disadvantages, what are the best materials and methods for electroplating CNC milling and 3D print metal parts, what are the applications and examples of electroplated parts in different industries, how to optimize the design and post-processing for electroplated parts, and what are the challenges and limitations of electroplating.

How Electroplating Works

Electroplating is a process that involves four components: an anode (the metal to be plated), a cathode (the part to be coated), an electrolytic solution (a liquid that contains salts and metal ions), and a power source (a direct current of electricity).

The anode and the cathode are placed in a bath of the electrolytic solution and connected to each other by wires. The power source sends a current to the anode, which causes the metal to dissolve into the solution as positive ions. The positive metal ions then move to the cathode, where they are deposited on the surface of the part as a thin layer of metal. The thickness and quality of the metal layer depend on factors such as the current intensity, the duration of the process, the temperature of the solution, and the concentration of the metal ions.

Advantages of Electroplating

Electroplating has several advantages for CNC milling and 3D printing metal parts. Some of them are:

- Increase the strength and durability of the parts by adding a protective layer that resists corrosion, wear, and abrasion.

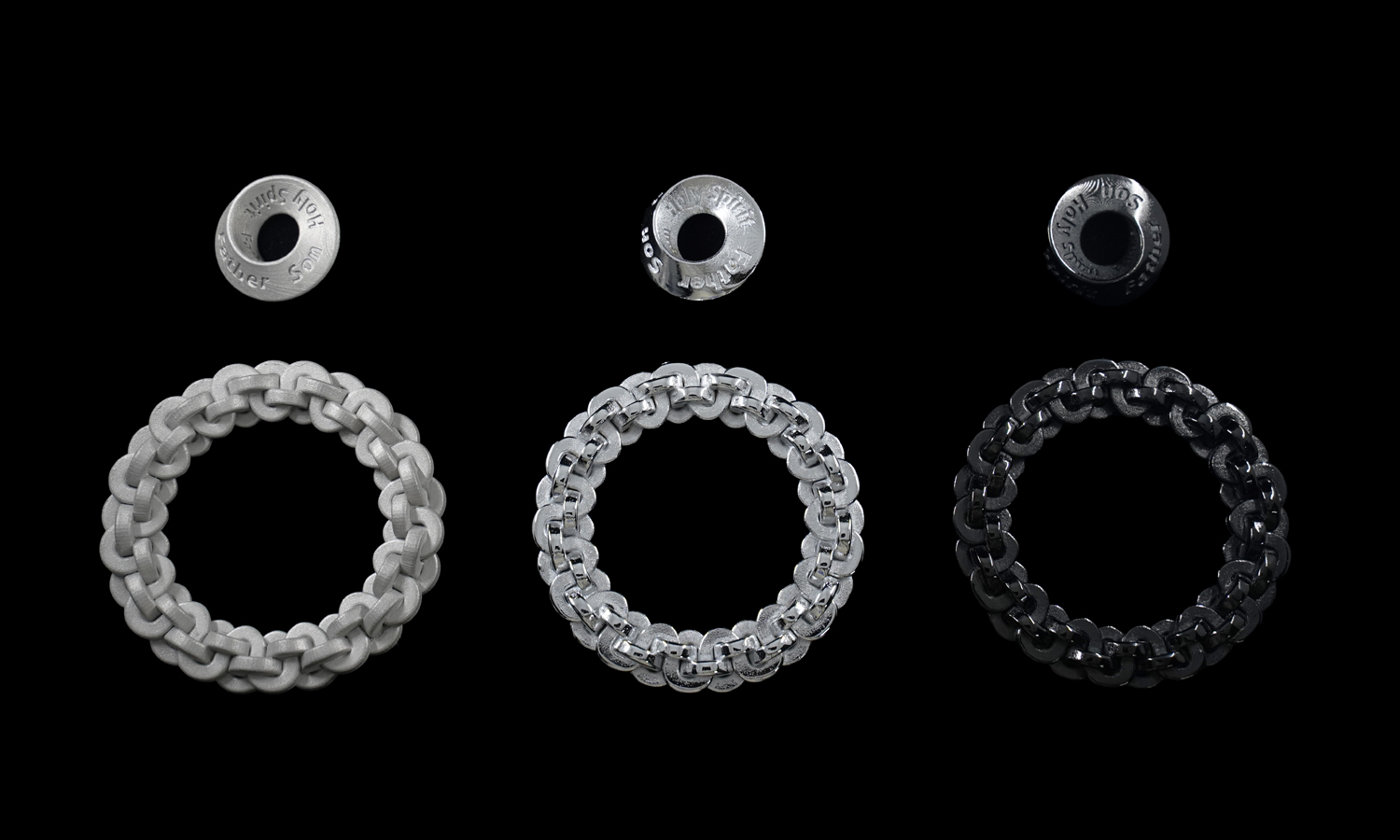

- Improve the appearance and aesthetics of the parts by adding a shiny or matte finish that enhances the color and texture.

- Modify the electrical conductivity of the parts by adding a layer that increases or decreases the resistance or capacitance.

- Reduce the cost and weight of the parts by using less material or replacing expensive metals with cheaper ones.

Best Materials and Methods for Electroplating CNC Milling and 3D Print Metal Parts

Electroplating can be applied to various materials and methods used for CNC milling and 3D print metal parts. However, some materials and methods are more suitable than others for electroplating. Here are some examples:

For CNC milling metal parts, electroplating can be done directly on most metals, such as steel, aluminum, brass, copper, etc. However, some metals may need a pre-treatment or an intermediate layer to improve adhesion or compatibility. For example, steel may need a zinc or nickel layer before plating with copper or gold.

For 3D print metal parts, electroplating can be done directly on some metals that are printed by powder bed fusion methods, such as direct metal laser sintering (DMLS) or selective laser melting (SLM). However, some metals may need a post-treatment or an intermediate layer to improve surface quality or conductivity. For example, titanium may need a polishing or etching before plating with nickel or chrome.

How to Optimize the Design and Post-Processing for Electroplated Parts

Electroplating can affect the design and post-processing of CNC milling and 3D print metal parts. Therefore, some considerations and best practices need to be followed to optimize the electroplating process and outcome. Here are some tips:

- Design for electroplating: Consider the shape, size, and geometry of the part to ensure a uniform and consistent coating. Avoid sharp edges, corners, holes, or cavities that can cause uneven plating or trapped air bubbles. Add features such as tabs or hooks that can facilitate the electrical contact and handling of the part during electroplating.

- Prepare for electroplating: Clean and degrease the part to remove any dirt, oil, or oxide that can interfere with the plating quality. Apply any pre-treatment or intermediate layer that can enhance the adhesion or compatibility of the metal coating. Choose the appropriate electrolytic solution and metal ions that match the material and purpose of the part.

- Control the electroplating parameters: Adjust the current intensity, duration, temperature, and concentration of the electroplating process to achieve the desired thickness and quality of the metal layer. Monitor the voltage, pH, and agitation of the electrolytic solution to prevent any irregularities or defects in the plating.

- Finish after electroplating: Rinse and dry the part to remove any excess solution or metal ions that can cause corrosion or contamination. Apply any post-treatment or final layer that can improve the surface quality or protection of the metal coating. Inspect and test the part to verify its performance and appearance.

Conclusion

Electroplating is a metal finishing process that can enhance CNC milling and 3D print metal parts in terms of strength, durability, and appearance. If you are looking for a reliable and professional electroplating service for your CNC milling and 3D print metal parts, look no further than FacFox. FacFox is a leading online platform that offers a wide range of manufacturing and finishing services, including electroplating. We can electroplate your parts with various metals and alloys, such as copper, zinc, nickel, gold, silver, etc.

FacFox can also handle any size and shape of parts, from small and intricate to large and complex. We will deliver your electroplated parts fast and affordably, with competitive pricing and fast turnaround time, and also provide you with expert advice and support throughout the electroplating process, from design to delivery.

FacFox is your one-stop shop for all your electroplating needs. Contact us today via info@facfox.com to get a free quote and start your electroplating project with us:)