The complete updated buyer’s guide to the best Polycarbonate 3D printers, plus learn how to 3D print with PC.

What Is It?

You may know polycarbonate (PC) as the headlight covers on your car or the safety glasses you use in your workshop. Polycarbonate is a reknown replacement for glass since it’s clear, 250 times more impact resistant than glass, and can be drilled without any problem of cracking. It’s tough, resistant to heat and chemicals, and ideal for 3D printing, provided you follow some guidelines.

PC is one of the world’s most popular plastics, and because it’s highly recyclable, it’s more popular than ever, used in engineering, consumer products, and manufacturing.

Its transparent nature, coupled with its durability, makes it ideal for 3D printed prototypes when you really want to see how parts fit together and for molds so you can inspect the quality. Naturally, it’s the go-to material for 3D printed lighting fixtures.

PC isn’t just clear, of course. It can take on colors and remain translucent or completely opaque. It’s also mixed with other plastics to boost impact resistance. For example, PC-ABS, which comes in black and white, is used for products, such as drone bodies and replacement parts that need more strength than ABS alone. You’ll also find PC with additives, including carbon fibers.

To print successfully with PC you’ll need a machine that can handle it. This means a 3D printer with a nozzle that reaches about 300 ºC, an enclosed chamber, and other features that boost your chances of a successful print.

Let’s take a closer look at this fascinating material and the best printers for PC.

Due to its transparency, PC can be used to prototype windows and other clear products that would cost much more if produced with other materials. High heat resistance means it can also be used to create functional prototypes where even ABS would warp under heat or stress.

One beautiful example is the Signify lamp series called 3D Printed Luminaires, which are manufactured on demand using a 100% recyclable polycarbonate material. This allows Luminaires to be tailored to a customer’s exact needs and recycled at the end of their life.

3D Printing with PC

Although you’ll find clear filament, polycarbonate (PC) filament printing differs from PLA and other filaments in several ways. This affects not only the properties of prints, but what you must do to achieve success.

PC is more durable and flexible than PLA but less so than nylon. It’s harder than ABS, PLA, or PMMA, while also being lighter and less dense than ABS. Its ability to withstand torsional stress is superior to other thermoplastics, and it’s flexible enough to be machine bendable at room temperature.

PC is:

- heat resistant up to 135 °C (for reference, PLA can begin to deform around 60 °C)

- highly durable

- impact and shatter resistant

- moderately flexible

- transparent

- electrically non-conductive

PC’s properties make it a bit more difficult to work with. Needless to say, you’re going to need to be prepared to tackle the following three challenges if you want successful prints:

- PC requires high temperatures to extrude properly (around 300 °C).

- PC is prone to warping and shrinkage.

- PC absorbs moisture.

Polycarbonate 3D printing can be difficult if you don’t take the proper precautions. The material is prone to warping and shrinkage during printing, so a consistent temperature must be maintained. Layers may not adhere to the bed or may separate or crack as the material cools and warps if not kept hot.

This makes a heated bed essential, and an enclosed chamber is highly recommended. The bed should ideally be between 135 °C and 150 °C.

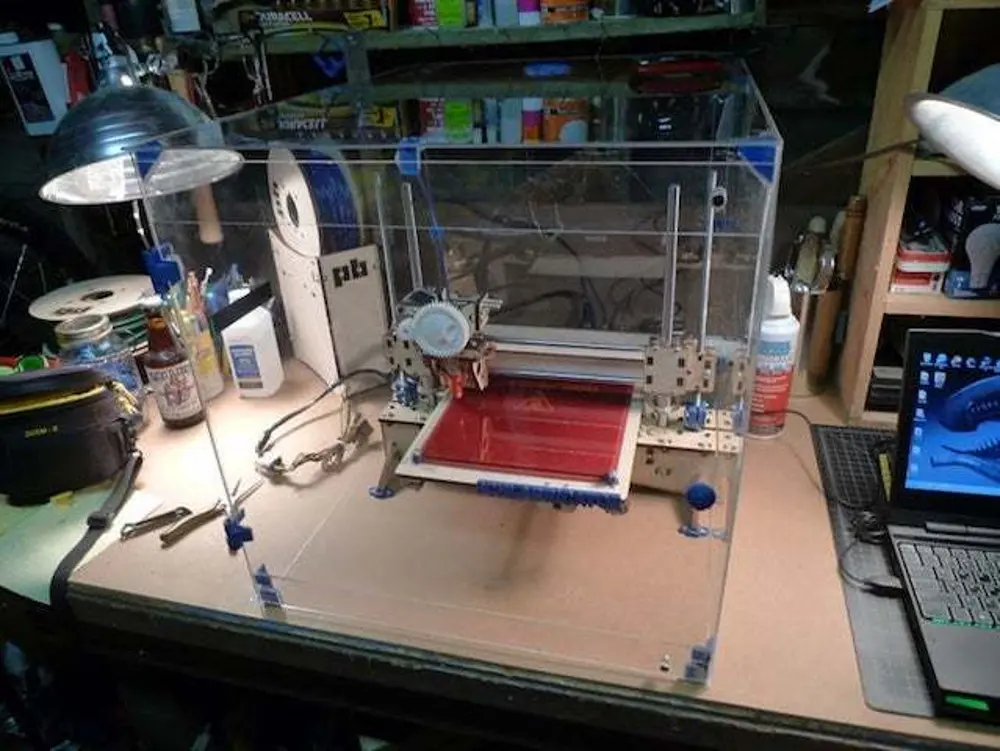

There are third-party adhesives you can try that claim to be useful for maintaining bed adhesion for PC. Sometimes, layers may not adhere, separating or cracking as the material cools and warps. If your preferred printer doesn’t have an enclosure, you may get by with an after-market solution or even a DIY enclosure option.

Similar to ABS, PC filament prints poorly if there’s airflow, which usually causes brittle prints. This is another argument for an enclosure and having the part-cooling feature turned off.

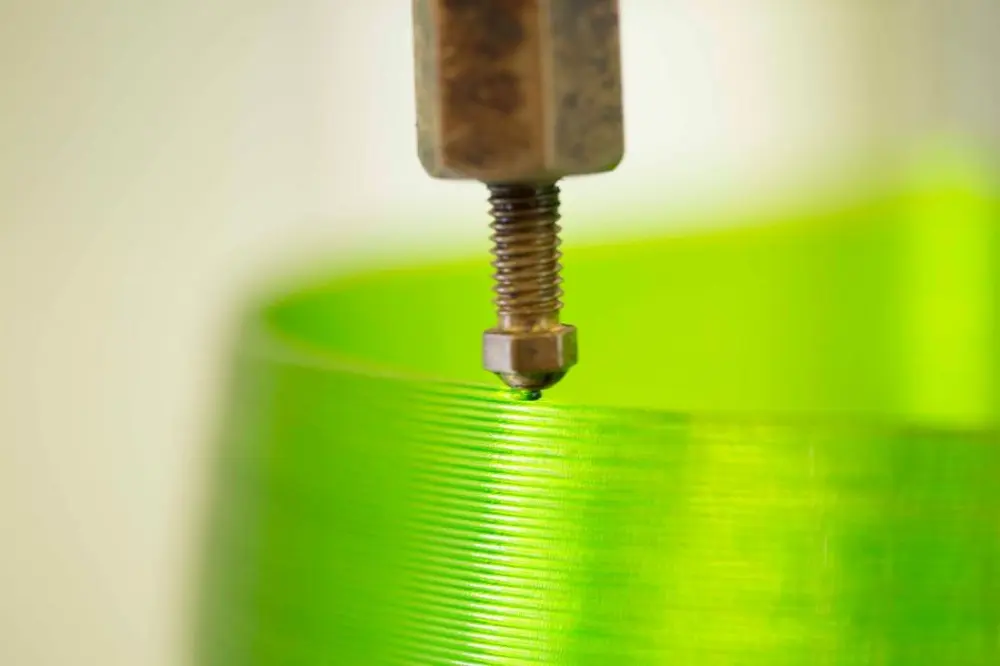

Hot Nozzle Required

PC requires a really hot, hot end, one that will ideally get to between 290 °C and 300 °C. If you’re going slow or using a composite PC filament, you may be able to get away with lower temperatures.

Temperatures too low or speeds too fast may cause jamming of your PC filament.

Material Oozing

PC also has a strong tendency to ooze while printing. If your printer doesn’t have a material setting for PC, you may need to tune it manually. If so, be sure to set your retraction settings to distances of no more than 10 mm to prevent jamming. Also note that PC generates strong fumes and odors. This is another reason why it’s usually best to print PC enclosed with a HEPA filter and a well-ventilated area.

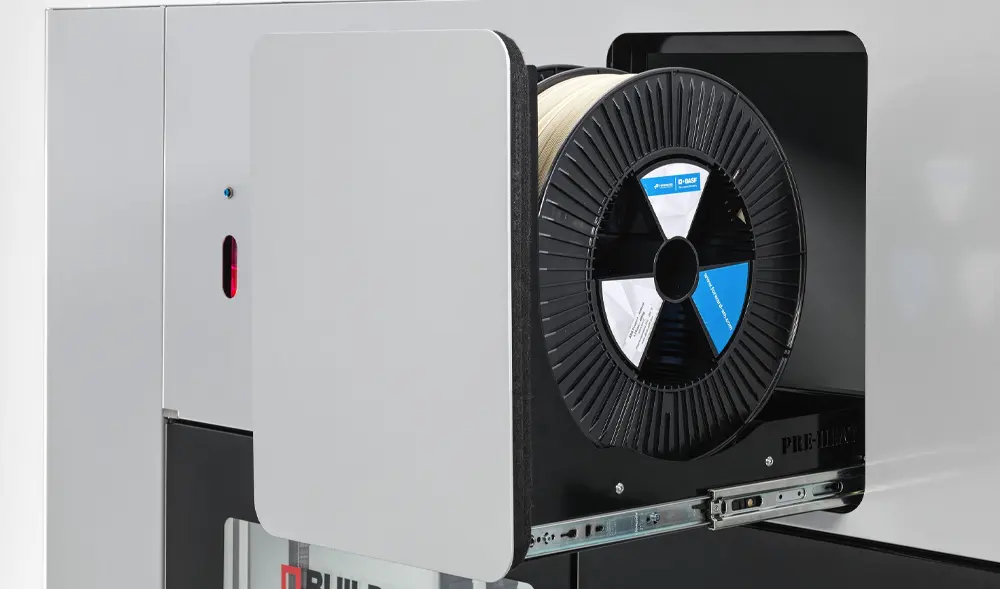

PC Filament Absorbs Moisture

PC absorbs atmospheric moisture, so keep it sealed when not in use (in a sealed container or moisture-controlled drying unit) and buy quality filament to avoid bubbles in your extruder and failed prints. Moisture will not only affect the integrity of the print but also prevent it from being optically transparent.

The recommended 3D printers below all come with an enclosed filament bay and built-in or optional filament storage. You may need to dry your filament before printing.

Best Polycarbonate 3D Printers

There’s no particular 3D printer that’s specifically made for polycarbonate, but if you consider all the 3D printer features that make for successful polycarbonate printing, it narrows your search.

Ideally, you’ll want an FDM 3D printer with:

- an enclosed heated or passively heated chamber

- a heated bed

- a hot end reaching 300 °C

- an enclosed filament bay

- an internal or attached filament drying/storage unit

- a HEPA air filter

Considering that you need to print polycarbonate hot and keep the build at a consistent temperature, this rules out all but professional 3D printers. Among the qualifying printers, there is a range of sizes and features.

The printers below are the best in class for polycarbonate.

Intamsys Funmat HT

The Funmat HT is manufacturer Intamsys’ starter machine (they have larger ones, too). It offers a variety of features that are typically limited to more advanced, industrial-grade 3D printers, which makes it a great intro to high-temperature printing. It has an insulated chamber for constant temperatures up to 90 °C, and a filament alarm, warning you when the filament is about to run out. Funmat HT has a built-in camera so you can monitor their print remotely, and the filament is enclosed, although there’s no drying unit. In addition to PC, it can process PEEK, PEI, Nylon, PPSU, Ultem, and ABS.

- Build Volume: 260 × 260 × 260 mm

- Mas Extruder Temp.: 450 ℃

- Max Platform Temp.: 160 ℃

- Chamber Temp.: 90 ℃

- Price: $6,500

Flashforge Creator 4

The Flashforge Creator 4 (versions 4-A & 4-S) is a large-format, dual extruder desktop 3D printer with a fully enclosed build chamber, which allows it to maintain a consistent temperature of up to 65 °C. There a HEPA air filter to negate those PC files and the removable print bed is both magnetic and flexible, which makes removing objects easier.

Creator 4 has three print head options and two can get hot enough for print PC. The independent dual extruders move independently of one another, enabling various print modes, such as duplication, where it can print two identical objects at the same time.

Pair the Creator 4 with the company’s optional filament dryer to ensure your PC filament is always ready to print.

- Build Volume: 400 x 350 x 500 mm

- Mas Extruder Temp.: 320 ℃

- Max Platform Temp.: 130 ℃

- Chamber Temp.: 65 ℃

- Price: $9,850

Fusion3 Edge 3D

Just released in 2022, the Fusion3 Edge 3D is the latest version of Fusion3’s high-temperature printer, replacing the F410.

Edge features a new, upgraded V3 extruder with a belt drive system and an upgraded filament detection monitor. This 3D printer boasts an ample 355 x 355 x 315 mm enclosed build volume with an optional HEPA and carbon filter air filter, which is now located within the 3D printer enclosure. The chamber is passively heated from the multizone print bed but can still maintain 70 ℃.

- Build Volume: 368.3 x 368.3 x 343 mm

- Max Extruder Temp.: 320 ℃

- Max Platform Temp.: 130 ℃

- Chamber Temp.: 70 ℃.

- Price: $6,999

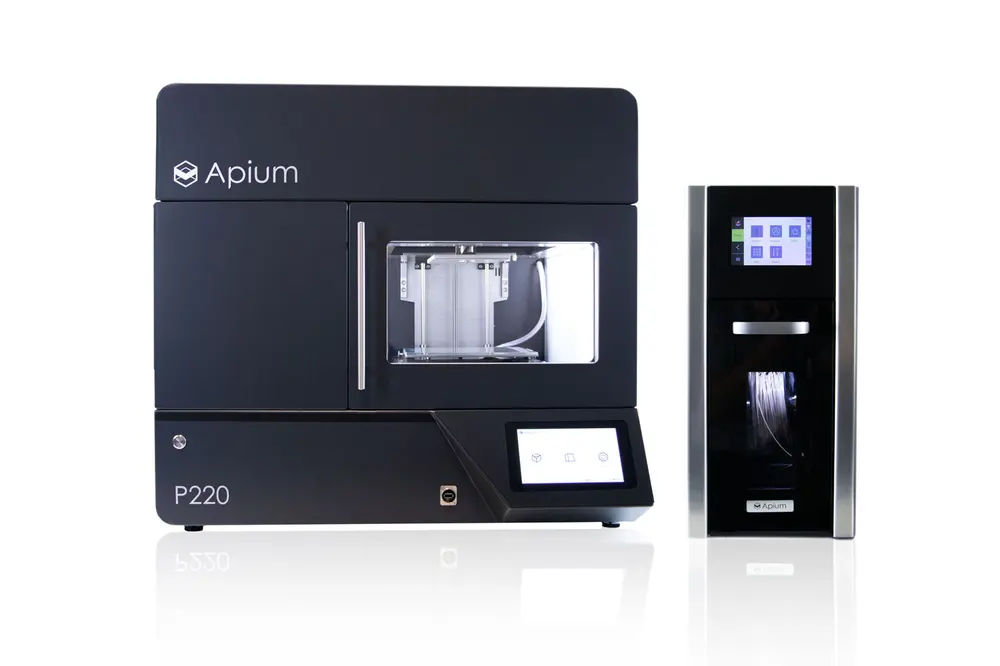

Apium P220

The P220 from manufacturer Apium, prints with a menu of high-temperature filaments, including PC, PEEK, PEI, and PEKK.

The company says its “adaptive heating system” can heat only the areas necessary and leave other areas cooler to ensure sufficient stiffness. This system analyses the printing geometry and adjusts the heading power accordingly. To monitor the printing process, the machine features an integrated camera and temperature recording that enables the printer to intervene independently when a deviation in the printing part occurs. The printer also lets you know when it needs maintenance.

The P220 is an open materials printer, which means you can print with PC from any brand.

Apium also offers the Apium Filament Dryer, which reduces moisture-related defects and significantly increases the success rate for prints.

It has a very low noise emission, which makes it suitable for an office environment. It also has an interchangeable nozzle and an easy filament change system.

- Build Volume: 205 x 155 x 150 mm

- Mas Extruder Temp.: 540 °C

- Max Platform Temp.: 160°C

- Chamber Temp.: 220°C

- Price: $46,000

Raise3D E2CF

Released in 2021, the E2CF is Raise3D’s dedicated carbon fiber machine, but it’s also ideal for PC. This independent dual extruder printer has a build volume of 295 × 240 × 240 mm and a layer height of 100 microns. It features a HEPA filter with activated charcoal, which makes it ideal for office environments.

To ensure a stable printing process, the E2CF is equipped with two standalone sealed dry boxes, developed by Raise3D to deal with the high water-absorption of materials like PC and nylon. These dry boxes are attached to the printer, allowing the materials to be kept in conditions of minimum humidity while printing. Another feature is the assisted auto-bed leveling process with a high-precision optical sensor for improved accuracy in nozzle height calibration.

- Build Volume: 330 x 240 x 240 mm

- Mas Extruder Temp.: 300 °C

- Max Platform Temp.: 110 °C

- Chamber Temp.: 70 °C

- Price: $4,500

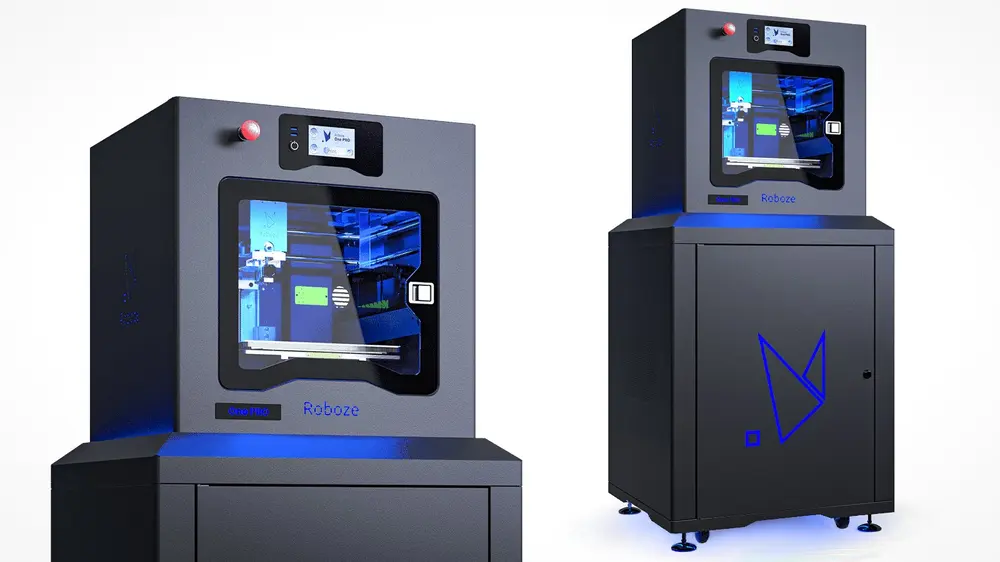

Roboze One Pro

Italian manufacturer Roboze’s One Pro 3D printer is a high-temperature machine capable of handling just about any advanced material. The One Pro features a beltless system that provides high precision and fast printing speeds, the company days.

Sensors offer build plate auto-leveling, which makes more durable and faster prints possible. The printer has the HT Dryer for preparing the material before 3D printing, drying, and heating it, thus guaranteeing surface quality and mechanical performance of the parts produced.

- Build Volume: 300 x 250 x 200 mm

- Mas Extruder Temp.: 350 °C

- Max Platform Temp.: 100 °C

- Chamber Temp.: 150 °C

- Price: $30,000

Best Large-Format Polycarbonate 3D Printers

If your goal is to produce large lighting fixtures, architectural accents, displays, or prototypes, including car and motorcycle design mock-ups, you’ll want a 3D printer with a large print volume, plus the features we outlined above.

Unfortunately, most large-format 3D printers do not have a heated chamber or bed, which would rule out PC. But there are some gems to pick from.

When it comes to material options, some large format 3D printers can print with PC in more affordable pellet form.

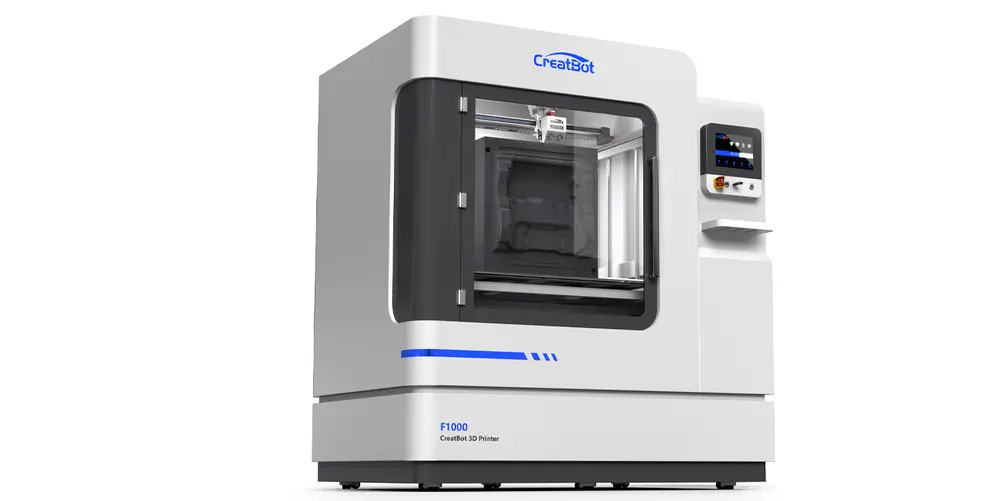

CreatBot F1000

The CreatBot F1000 was created to make industrial 3D printing large-scale objects and prototypes as easy as possible, this Chinese manufacturer says. The F1000 features a dual extruder kit, an enclosed heated chamber, an automatic leveling system, and camera control. With a fast-heating platform and hot chamber, this high-resolution large-print workhorse prints with a wide range of materials.

Ensuring your large prints are ruined by a material or power outage, CreatBot technology automatically memorizes the current extruder position and will continue to print from the last stopped point after material or power is restored.

- Build Volume: 300 x 250 x 200 mm

- Mas Extruder Temp.: 420 °C

- Max Platform Temp.: 100 °C

- Chamber Temp.: 60 °C

- Price: $30,000

Titan Robotics / 3D Systems Atlas-HS

Titan Robotics, the Colorado-based company that was just purchased by 3D Systems, specializes in large-scale 3D printing solutions for a variety of industries. Its Atlas-HS multi-head hybrid FDM 3D printer and CNC machine incorporates the pellet extrusion system seen on its line of smaller Atlas 3D printers with a 3-axis milling system.

The Atlas-HS features a heated chamber for printing high-performance polymers, including PC, carbon fiber-PEI, glass fiber-PEKK, and nylons. With a print volume of 1,270 x 1,270 x 1,829 mm, the Atlas-HS gives industrial customers the option to incorporate both Titan’s pellet and filament extruders on the same gantry.

“The Atlas-HS industrial users to 3D print a near-net-shape part with pellet extrusion and then post machine it to meet final part requirements, as well as produce complex geometries with in-situ machining capabilities,” says Bill Macy, Titan Robotics’ CTO.

- Build Volume: 1,270 x 1,270 x 1,829 mm

- Mas Extruder Temp.: 400 °C

- Max Platform Temp.: 140 °C

- Chamber Temp.: 80 °C

- Price: $250,000

Builder Extreme 1500 Pro HC

Large format 3D printer maker Builder offers a menu of FDM 3D printers, but the new Extreme 1500 Pro Heated Chamber is ideal for PC. The chamber reached 70 °C and the extruder 350 °C.

Made for making molds, tooling, and end-use parts, the newly developed print head is water-cooled and available in different nozzle diameters to optimize the print quality and speed for their specific project. The machine is fully insulated to make sure no heat is lost during the printing process. Even the filament drawer is passively heated, making sure your PC filament remains in optimal condition. You can even place a second spool in the drawer so it can be dried pre-printing.

Naturally, there’s a BOFA air filter system.

- Build Volume: 1,100 x 500 x 820 mm

- Mas Extruder Temp.: 350 °C

- Max Platform Temp.: 1o0 °C

- Chamber Temp.: 70 °C

- Price: $50,000

Best Polycarbonate Materials

As we mentioned, PC comes in various brands and blends. There are even medical-grade PC materials in both filaments and granules.

In our frequently updated guide below to the best PC filaments, you’ll find details of the 10 best on the market and some specialized brands.