Understand PETG vs. PLA to see if your next project calls for the more durable PETG or the environmentally friendly and easy-to-use PLA.

When it comes to choosing 3D printing materials, there are a lot of factors that you may look at, such as printability and strength. Of course, depending on what you’re printing, what you want most may differ. For example, if you’re printing a GoPro mount, you may want a filament that can withstand the elements, but for making a fun toy for your nephew, a filament that’s easy to print with would work fine.

PLA and PETG are two of the most popular filament materials available to hobbyists, both with their advantages and disadvantages regarding printability, strength, and more. In this article, we’ll review the main differences between PLA and PETG and what makes each material better suited for specific applications and purposes.

3D Printing Materials – The Ultimate Guide

The Contenders

Before we look at the differences between PLA and PETG, it’s important to review each filament material on its own merits. So first, we’ll go over how each material is sourced, as well as the main benefits and disadvantages of each.

PLA

First up, PLA is the commonly used abbreviation for polylactic acid. PLA is the most popular 3D printing filament material and is also commonly used in the food packaging industry due to its food safety properties, which we’ll talk about later.

To give some background, raw PLA plastic is sourced from crops like corn and sugar cane. Plant starch is extracted from the crops, and a type of sugar is extracted from the starch by mixing it with special chemicals. The sugar is then fermented and either condensed or polymerized to create the raw version of PLA plastic.

Perhaps the most notable aspect of PLA is how easy it is to print with. Basically any FDM 3D printer can print with PLA due to its low melting and glass transition temperatures. Additionally, PLA isn’t super sensitive to the surrounding environment and works with a range of slicer settings, so you can achieve decent prints without too much work.

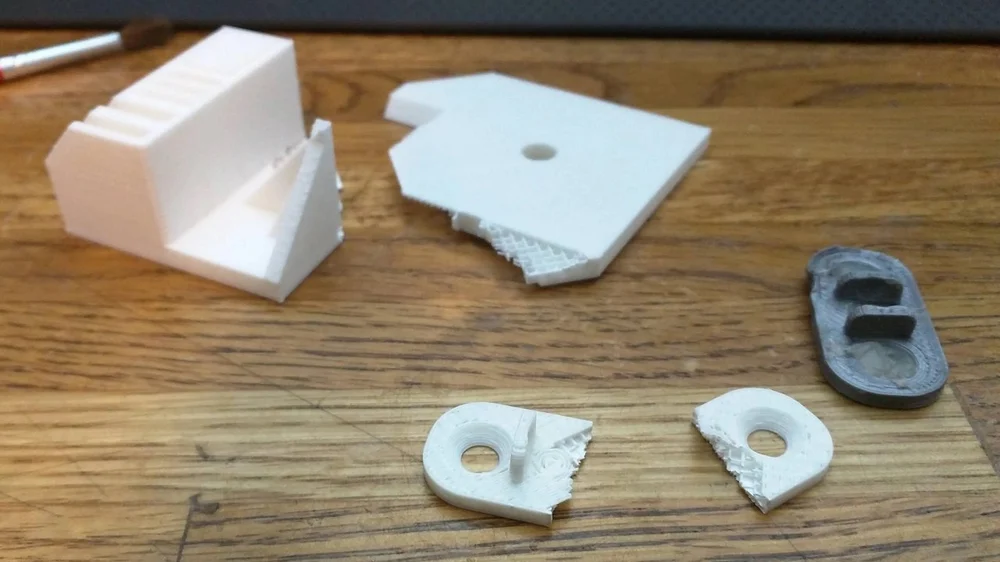

However, no material is all good, and the main downside of PLA is its lack of strength. Parts printed in PLA are known to be very brittle due to the low layer-to-layer adhesion of 3D printed models. Also, high temperatures and UV rays are known to discolor and even deform parts printed in PLA, making it a poor material choice for parts meant to be outside and under the sun.

PETG

Polyethylene terephthalate glycol-modified, or PETG, is another popular 3D printing material. PETG is a modified version of PET, the plastic you likely associate with disposable water bottles and other clear containers. The main difference between PETG and PET lies in the ‘G’, which signifies the glycol modification that lowers PETG’s melting point and makes it easier to 3D print.

Like its base material, PETG is mainly sourced from crude oil, specifically the chemical components ethylene glycol and terephthalic acid. These chemicals are extracted from the oil and then heated and mixed to create raw PETG plastic. While oil obviously isn’t the most environmentally friendly resource, many recycling centers accept PETG, so this type of plastic isn’t completely harmful to the environment.

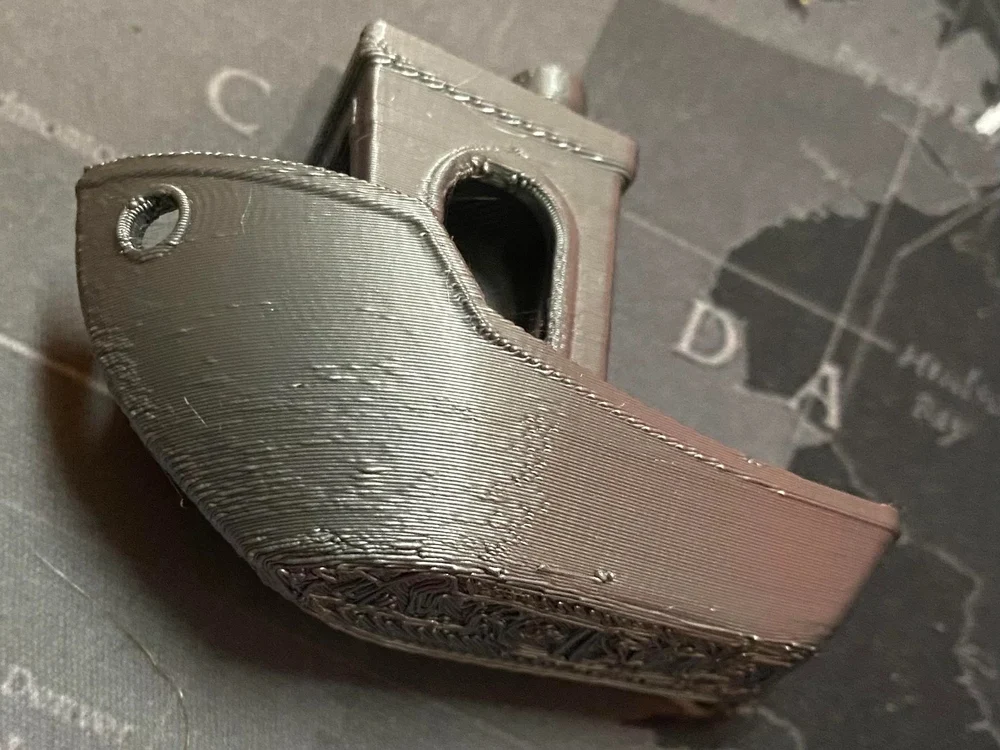

PETG is best known for its durability and strength, and the plastic is resistant to high temperatures, UV rays, water, chemical solvents, and more. All of this makes PETG an ideal filament material option for printing parts that will exist in harsh environments or have to undergo a lot of physical stresses.

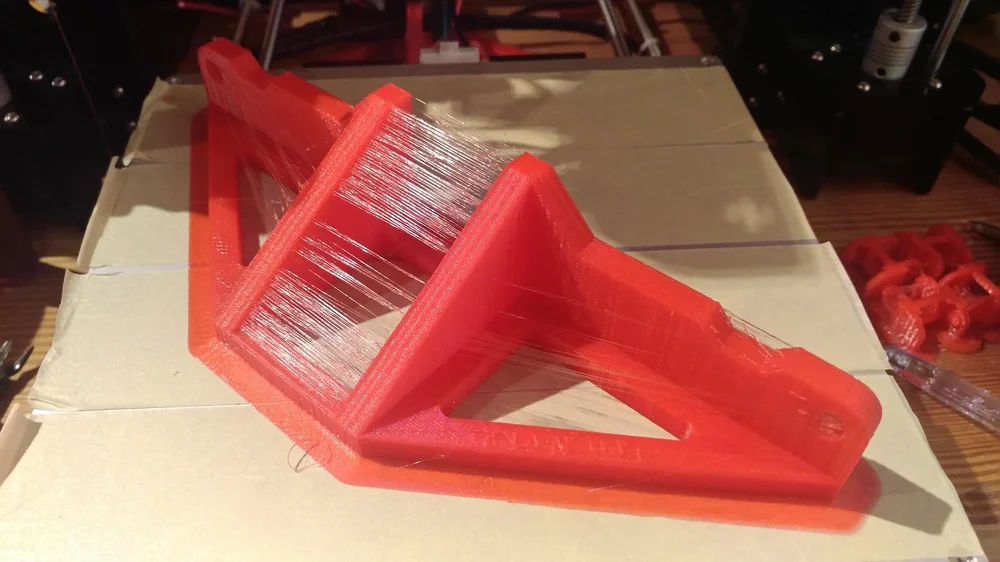

Unfortunately, PETG requires somewhat high printing temperatures, which limits the number of compatible printers. Additionally, there are a few common printing and part quality issues, like over-adhesion and stringing, that make the material more difficult to work with. Nonetheless, PETG is still a great filament material option with a lot of applications.

Printing

As we mentioned, PLA requires comparatively low printing temperatures. Most PLA filaments can be printed with a nozzle temperature of around 210 °C and an optional bed temperature of up to 60 °C. On the other hand, PETG requires notably higher temperatures, with a suggested nozzle temperature between 220 °C and 250 °C and a bed temperature around 75 °C. While a difference of 15 °C may not seem like much, it’s a significant enough variation that means that more printers are able to print with with PLA than with PETG.

PLA is also a lot less sensitive to printing factors, such as the printing environment and imperfect slicer settings, compared to PETG. It’s not uncommon to achieve high-quality prints in PLA with a default PLA printing profile.

However, PETG is a little more difficult to work with. Especially if you don’t calibrate your extruder, tune your retraction settings, and find the best temperatures and speeds, you’ll likely experience stringing on your PETG prints.

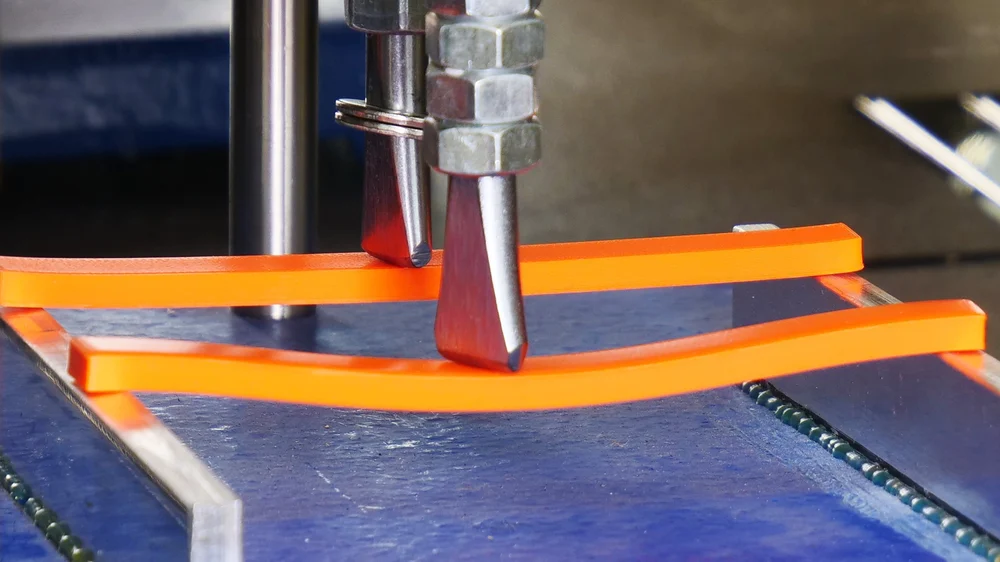

If you’re unfamiliar with the problem, stringing is when extra material flows out of the nozzle when it shouldn’t, leaving small wisps of extra plastic all around your print (it’s not a good look). With PETG, you’re also more likely to have issues with bed adhesion, as the filament tends to over-adhere to the build plate, making it more difficult to remove prints from the bed compared to PLA.

Mechanical Properties

In terms of mechanical properties, PETG is well-known for its high strength, which is a result of the raw material’s natural strength combined with the increased layer-to-layer adhesion produced with the higher printing temperatures. PLA’s layer adhesion is less impressive, and PLA prints can be extremely brittle, making this material far from the best option for a print that will face any tension. PETG isn’t just strong compared to PLA, though; parts printed in PETG, when printed with optimal settings, usually can’t be broken by bending them with your hands (depending on the model, of course).

While strength is one thing, resistance to the elements, which we’ll refer to as durability, is also very important for a 3D printing material. If you’ve ever printed with PLA, you’ll know that it’s not super durable. For example, if left outside and under the sun for more than an hour, parts printed in PLA will start to deform because the UV rays and warm temperature are enough to soften the material.

This is not anywhere near the case for PETG, though, as this thermoplastic material is one of the most durable plastics, not just in 3D printing but in manufacturing as a whole. PETG’s got a long list of things that it’s resistant to, including UV rays, high temperatures, water, and acetone. All of this makes PETG a great option for printing any models that will be used outdoors or face harsh environments.

More Differences

It’s more than the properties of the materials and how to print them that set PLA and PETG apart. For one, there’s the environmental friendliness of the materials. PLA tends to come from natural sources like corn crops, while PETG comes from less-than-environmentally-friendly crude oil.

While producing PLA is, therefore, less harmful than making PETG plastic, this doesn’t end the debate over which material is more environmentally friendly. PETG is a recyclable plastic that can be dropped off at recycling centers to be melted down and hopefully repurposed. Unfortunately, PLA isn’t generally recyclable, and there’s not a lot you can do with wasted PLA prints. And while PLA is biodegradable and PETG isn’t, it can take hundreds of years for parts printed in PLA to fully degrade, even in optimal conditions.

With everything in mind, neither plastic is particularly friendly for the environment. However, if one had to be a winner, PLA would likely take the cake due to its natural source materials and biodegradability.

And although it’s not a difference, it’s also important to know that both PETG and PLA are generally considered food safe. This means you can put food and liquids inside parts printed with these materials without a significant risk of the plastic contaminating the food or liquid. If you’re looking for the safest filaments for food contact, you should look for one with FDA approval, or the approval of your local equivalent authority.

Examples

Now that we’ve gone over the differences between PLA and PETG, you might be interested in getting some filament in either material.

PLA Filaments

Hatchbox is a well-known manufacturer of 3D printing materials, and their PLA filament is known to be very easy to print, like many PLA options. Hatchbox PLA comes in 20 different colors, and the company states that its filament maintains a diameter tolerance of just ±0.03 mm.

Overture is another manufacturer of 3D printing filaments, and Overture PLA is available in 30 colors, including blue, red, yellow, and every other color in the rainbow. The filament has a diameter tolerance of ±0.03 mm, which means you shouldn’t run into too many extrusion issues related to the consistency of the filament. Overture filaments also come on cardboard spools that feature helpful lines for measuring how much filament you have left.

PETG Filaments

Overture also makes its own PETG filament, which is another option worthy of being mentioned due to its amazing user reviews that suggest that the filament is super strong and fairly easy to print. Like the PLA filament, Overture’s PETG has a ±0.03 mm diameter tolerance. Additionally, the filament comes in almost 20 different colors, like black, dark green, magenta, and more!

Sunlu‘s PETG filament is another great option and is very inexpensive, costing only around $15 per 1-kg spool. According to the manufacturer, Sunlu PETG keeps up a ±0.02 mm diameter tolerance which is very impressive considering the super low price point. Unfortunately, Sunlu’s PETG filament is only available in a couple of colors, like black, white, and gray, but it makes a great choice for functional prints where the color isn’t a priority.

Source: https://all3dp.com/2/petg-vs-pla-3d-printing-filaments-compared/