Looking to 3D print with stronger-than-metal PEEK polymer? Our buyer’s guide covers all you need to know and the best PEEK 3D printers for your application.

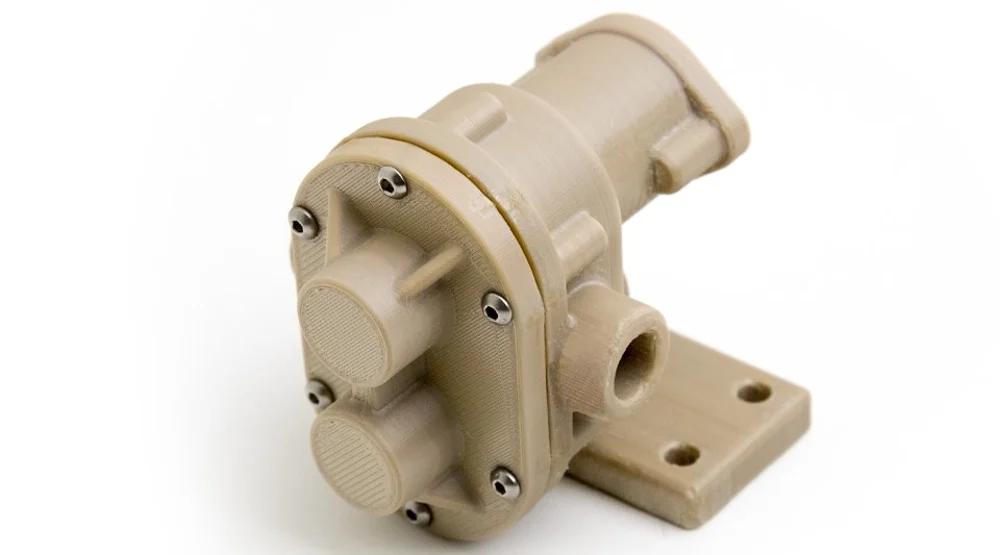

PEEK (polyetheretherketone) is one of the most popular thermoplastics in manufacturing and for good reason. PEEK can produce parts stronger and lighter than stainless steel and aluminum with extremely high thermal, chemical, and wear resistance. Parts made from this engineering-grade material can be found in virtually every industry.

PEEK is prized for delivering better-than-metal medical implants and aerospace components because of its high strength-to-weight ratio. It’s ideal for parts in electrical engineering due to its electrical insulation properties, and it’s widely used in applications requiring long-term resistance to pressure and wear, such as in the oil and gas industry.

Couple the qualities of this plastic with the capabilities of 3D printing and you have the ability to make just about any customized shape and part complexity in a material that can withstand the harshest conditions. It’s no wonder we’re seeing more use of 3D printed PEEK parts replacing metal in space craft, orthopedic implants, and even engine parts in high-performance auto racing.

At the same time, demand for 3D printers that can work with this material is growing, which has prompted manufacturers to produce increasingly affordable, larger, and easier-to-use PEEK printers for businesses looking to bring production and prototyping in-house.

Although PEEK is still among the costliest additive manufacturing polymers (yet cheaper than most metal), and it’s not the easiest to work with, it is far more accessible today than ever before. Below we detail the best 3D printers in a range of sizes and price points, from office-friendly desktop versions to large-volume production machines. Plus, if you’re new to PEEK (and other polymers in the PEAK family), skip down to the end to learn more about this sought-after and functional material.

| PEEK 3D Printer | Build Volume (mm) | Technology | Price | Max. Extruder Temp. | Max. Bed Temp. | Max. Chamber Temp. | Min. Resolution |

|---|---|---|---|---|---|---|---|

| Apium M220 | 130 x 130 x 120 | FDM | – | 540 °C | – | 280 ºC | – |

| Kumovis R1 | 180 x 150 | FDM | – | 500 °C | 300 °C | 250 °C | 200 microns |

| WASP 4070 TX | 400 x 400 x 600 | FDM | – | 500 ºC | 120 ºC | 250 ºC | 50 microns |

| Intamsys Funmat HT | 260 x 260 x 260 | FDM | $6,000 | 450 °C | 160 °C | 90 °C | 50 microns |

| Zortrax Endureal | 300 x 400 x 300 | FDM (dual extruders) | $58,000 | 480 ºC | 220 ºC | 200 ºC | 200 microns |

| Aon-M2+ | 450 x 450 x 640 | FDM (IDEX) | $50,000 | 500 °C | 200 °C | 135 °C | 1 micron |

| MiniFactory Ultra | 330 x 180 x 180 | FDM (Dual Extruders) | $50,000 | 480 °C | 250 ºC | 250 ºC | 10 microns |

| Roboze One+400 Xtreme | 300 x 250 x 220 | FDM | $50,000 | 500 °C | 150 °C | – | 15 microns |

| Apium P220 | 205 x 155 x 150 | FDM | $46,000 | 540 °C | 160 °C | 220 ºC | 50 microns |

| 3DGence Industry F340 | 260 x 300 x 340 | FDM (dual extruders) | $30,000 | 500 °C | 160 °C | 85 °C | 40 microns |

| CreatBot PEEK-300 | 300 x 300 x 400 | FDM (dual extruders) | $17,000 | 500°C | 200°C | 120°C | 40 microns |

| Stratasys Fortus 450mc | 406 x 355 x 406 | FDM | $160,000 | 450 °C | 250 °C | 350 °C | 130 microns |

| Tractus3D T850P | 280 x 280 x 400 | FDM | $15,000 | 450 °C | 175 °C | 80 °C | 10 microns |

| Essentium HSE 180 HT | 690 x 500 x 600 | FDM (IDEX) | $149,000 | 550 °C | 100+ °C | 200 °C | 5 microns |

| 3ntr Spectral 30 | 300 x 300 x 300 | FDM (Quad Extruders) | $110,000 | 500 ºC | 300 ºC | 250 ºC | 5 microns |

Not All Printers Can Print PEEK

A spool of PEEK filament may look like any other 3D printing plastic, but put it in a consumer machine and you’ll quickly realize that this material needs something more; specifically more heat.

You not only need to extrude PEEK with a super-heated nozzle (300+ ºC), you also need to keep it hot with a heated bed and a heated chamber. The heat needs to be consistent and controlable since how quickly you let the final part cool down also makes a difference. Plus, print speed and layer height are important factors in a successful PEEK print. Fortunately, the better PEEK printers will automate many of these settings for a more worry-free experience.

Although most PEEK is 3D printed using FDM printing with rolls of filament, more recently PEEK is making headway in powder form for selective laser sinter (SLS).

PEEK Printers Can Print More Than PEEK

No 3D printer on our list is a one-trick pony; if they can print PEEK, then they have the capability to handle other high-performance polymers that have similar print perimeters and a need for high heat, such as PEAK, PEKK, PEI/Ultem, PPSU, and others. Of course, they can handle regular ABS and even PLA if you can turn the heat down low enough.

What To Look For in a PEEK Printer

Not all PEEK printers are the same, of course, and you’ll need to balance your budget with the features you need in a printer and the ones you might be able to live without. If you only need PEEK part occasionally or aren’t sure you need PEEK at all, try ordering your PEEK parts from a 3D printing on-demand service bureau, such as Craftcloud.

Below are some of the top features of the PEEK printers on our list.

- HEPA filter to trap harmful fumes and particles

- Insulated chamber so the heat doesn’t warm up your workshop or leak heat from your machine

- Rapid heating chamber so you’re not waiting an hour or more before you can start printing

- Dual extruders so you can print support material in something other than PEEK, such as a soluble material, for cost savings and easier removal

- Integrated filament dryer so your PEEK material is always ready to go

- Controlled cool down to prevent warping

- Rapid print speed

- Camera embedded for continuous print monitoring

- Power outage protection that resumes the print from where you left off

- Sensors to detect whether you have enough filament to complete the job

- Sensors to detect a filament jam

DESKTOP / BENCHTOP 3D PRINTERS

The following printers are small enough to fit on a desktop and can print small parts, batches of small parts, and prototypes. These versions may lack some of the bells and whistles of their larger cousins but can still produce metal-like parts with all of the characteristics you print with PEEK for. These machines could be considered more office-friendly in the sense that they’re small, but you’ll still want to follow good safety and ventilation procedures.

Intamsys Funmat HT

- Technology FDM

- Price $6,000

- Max. Extruder Temp. 450 °C

- Max. Bed Temp. 160 °C

- Max. Chamber Temp. 90 °C

- Min. Resolution 50 microns

The Funmat HT is Chinese manufacturer Intamsys‘ starter machine (they have larger ones, too). It offers a variety of features that are typically limited to more advanced, industrial-grade 3D printers, which makes it a great into to PEEK printing. It has an insulated chamber for constant temperatures up to 90 °C, and a filament alarm, warning the user when the filament is about to run out. Funmat HT comes with a built-in camera, so users can monitor their print remotely. In addition to PEEK, it can print in PEI, Nylon, PPSU, Ultem, and ABS.

Intamsys’ larger workshop offerings for PEEK printing include the Funmat Pro 410 and the larger Pro 610 HT. The 410 is a larger version of the Funmat HT (305 × 305 × 406 mm) with a nozzle that can get a bit hotter. It features dual nozzles, a heated filament box, power failure recovery so you can pick up where you left off with a print, a liquid cooling system for more consistent temperature control, and something the company calls over-heat protection.

The Pro 610 HT machine offers everything on the 410 but a massive build volume (610 x 508 x 508 mm) and time-saving features like automatic bed leveling, auto-cleaning nozzles, filament monitoring, and WiFi connectivity.

All Intamsys printers are open-material machines so you can choose your filament brand and type.

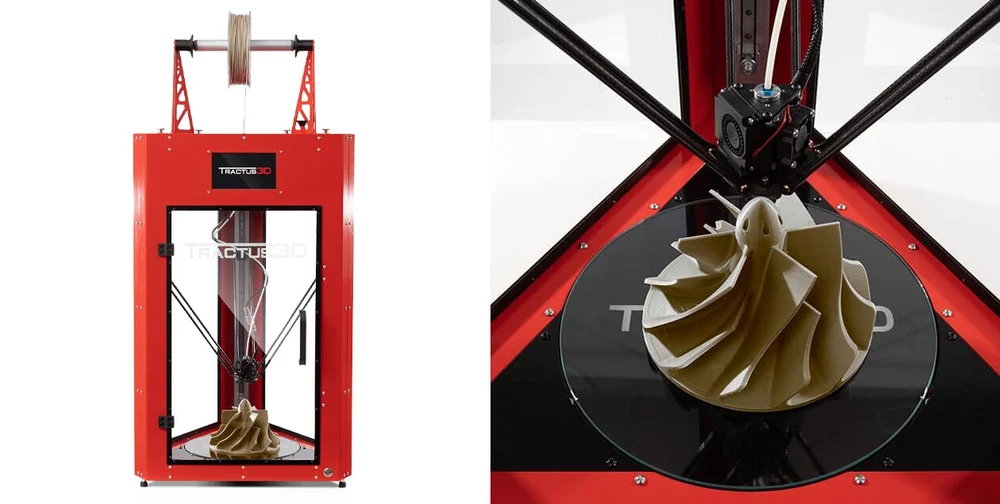

Tractus3D T850P

- Technology FDM

- Price $15,000

- Max. Extruder Temp. 450 °C

- Max. Bed Temp. 175 °C

- Max. Chamber Temp. 80 °C

- Min. Resolution 10 microns

The T850P is a desktop PEEK and PEI 3D printer manufactured by the Netherlands-based company Tractus3D.

It’s the only desktop delta printer capable of printing with PEEK in this guide (WASP below has a larger delta) and is constructed of an aluminum and polycarbonate frame, making it both lightweight yet stable. It’s equipped with a 5-inch touchscreen, automatic bed-leveling, and a filament sensor.

The 3D printer enables you to create prototypes out of materials, such as carbon-filled PEEK, PEEKQ, and Ultem, and conventional materials, including PLA and PETG.

CreatBot PEEK-300

- Technology FDM (dual extruders)

- Price $17,000

- Max. Extruder Temp. 500°C

- Max. Bed Temp. 200°C

- Max. Chamber Temp. 120°C

- Min. Resolution 40 microns

China-based CreatBot offers the PEEK-300 3D printer that can produce parts in a wide variety of high-performance materials, from PLA and TPU to Nylon, Ultem, PVA, and of course PEEK, plus about eight others. Its dual extruders come in handy for printing support materials.

CreatBot offers more than half a dozen printers but launched the PEEK-300 in 2019 to address the growing demand for printers with the features that can produce parts in this demanding material, such as a superheated hot end, print bed, and chamber.

The PEEK-300 also offers a build platform with a carbon fiber sheet for easier part removal and a HEPA air filtration to adsorb impurities and gases that are generated by printing polymers at high temperatures.

The company’s smaller CreatBot F430 also prints with PEEK although it doesn’t get quite as hot.

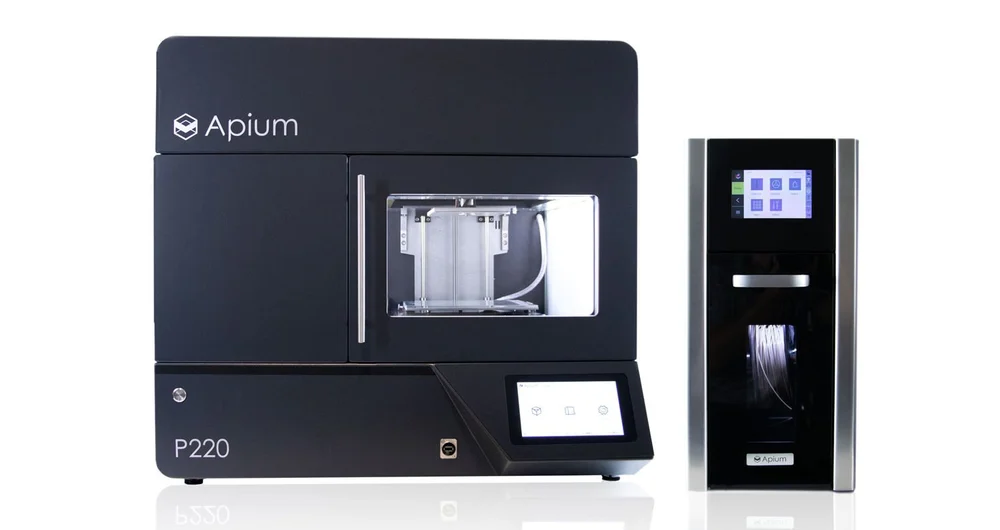

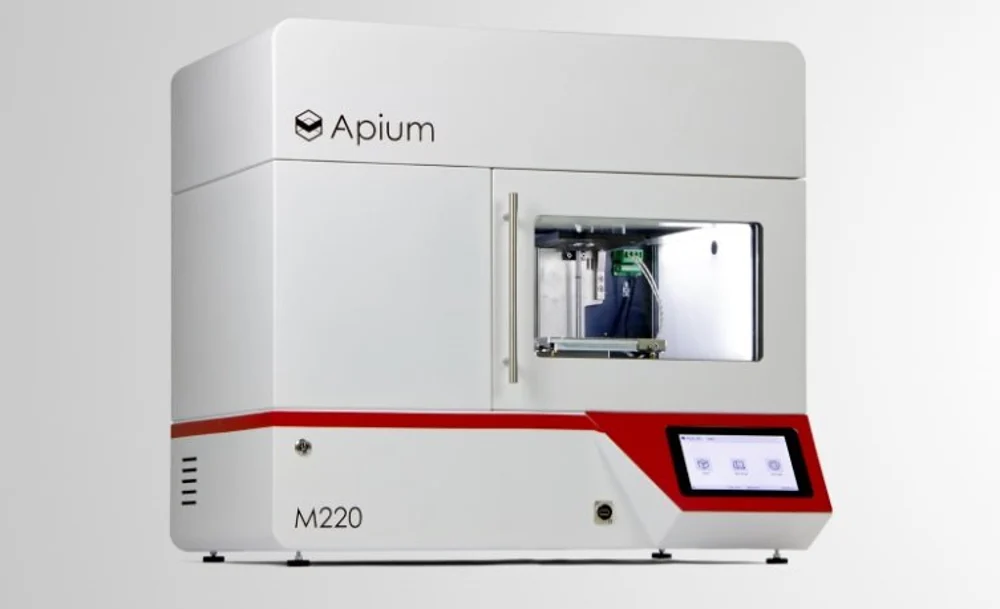

Apium P220

- Technology FDM

- Price $46,000

- Max. Extruder Temp. 540 °C

- Max. Bed Temp. 160 °C

- Max. Chamber Temp. 220 ºC

- Min. Resolution 50 microns

The P220, from the German manufacturer Apium, prints with PEEK, PEI, PEKK, and carbon fiber PEEK (not continuous carbon fiber) and glass PEEK.

The company says its “adaptive heating system” can heat only the areas necessary and leave other areas cooler to ensure sufficient stiffness. This system analyses the printing geometry and adjusts the heading power accordingly. To monitor the printing process, the machine features an integrated camera and temperature recording that enables the printer to intervene independently when a deviation in the printing part occurs. The printer also lets you know when it needs maintenance.

The P220 is an open materials printer, which means you can print with just about anything, even metal-filled filaments leading to metal parts (after sintering).

Apium also offers the Apium Filament Dryer, which reduces moisture-related defects and significantly increases the success rate for prints.

It has a very low noise emission, which makes it suitable for an office environment. It also has an interchangeable nozzle and an easy filament change system.

Zortrax Endureal

- Technology FDM (dual extruders)

- Price $58,000

- Max. Extruder Temp. 480 ºC

- Max. Bed Temp. 220 ºC

- Max. Chamber Temp. 200 ºC

- Min. Resolution 200 microns

The Polish 3D printer maker Zortrax offers its dual extruder Endureal printer with thermal management ideal for high-performance polymers like PEEK. The filament temperature is tightly monitored and controlled throughout the printing process in order to achieve the best precision and optimum mechanical material properties, the company says.

The printer features an automatic annealing function that can be carried out after printing to elevate parts’ mechanical properties. The printer also features a heated filament cabinet, power outage protection, a camera built into the chamber to provide live video of the print in progress, and sensors to detect and alert when the filament is jammed or empty. These sensors can also tell you if you have enough filament loaded to complete your job.

The network-enabled Endureal can be remotely managed with Zortrax inCloud 3D printing management service.

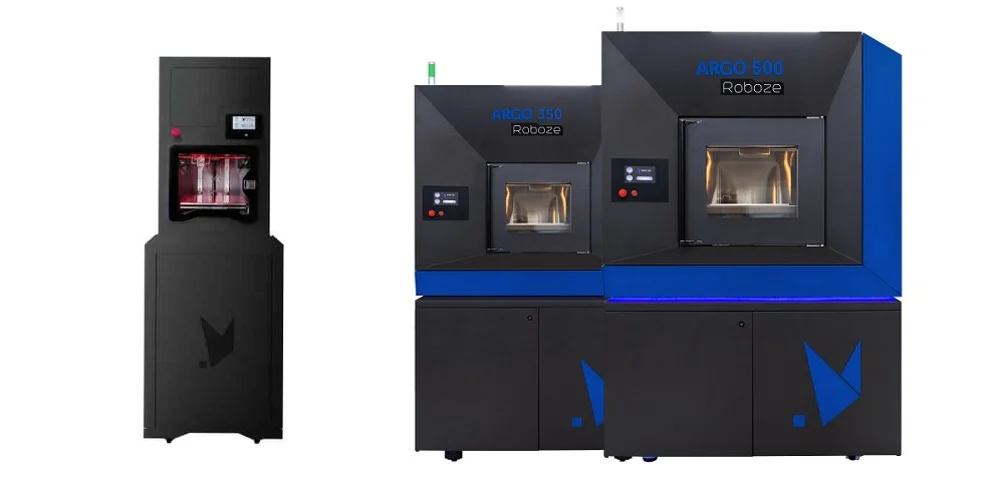

Roboze One+400 Xtreme

- Technology FDM

- Price $50,000

- Max. Extruder Temp. 500 °C

- Max. Bed Temp. 150 °C

- Max. Chamber Temp. –

- Min. Resolution 15 microns

Roboze is an Italian 3D printer manufacturer that specializes in high-temperature machines with four PEEK-compatible options: the desktop-size One+400 Extreme and the larger, industrial Argo 350, Argo 500, and enormous Argo 1000 with a build volume of 1000 x 1000 x 1000 mm due out in 2022.

The company has a lot of experience with PEEK and its smallest printer, the One+400 Extreme, offers many features typically reserved for more industrial version, such as complete automation of all stages of the print process from loading the material to calibrating the build plate. Although the One+400 doesn’t have a heated chamber, the larger versions do.

Materials for the One+400 Extreme range from PLA and ABS to flexible TPU and of course PEEK, including Carbon PEEK (PEEK with embedded chopped carbon fibers).

All Roboze machines feature what the company calls its Beltless System. By eliminating the rubber belts typically used in 3D printers and introducing a patented movement with gears, Roboze says its printers can deliver better accuracy and repeatability.

Roboze doesn’t disclose the prices of all of its units but we do know that the Argo 500 is accessible under a subscription plan, rather than buying the machine outright. Depending on your level of services, updates, and customization, the annual range is between $89,000 and $119,000.

For PEEK printing in a more industrial capacity, these printers should do the trick. They require a little more expertise to get running (and sometimes a lot of space), but they’re designed to be efficient and come with a lot more features and build volume.

3ntr Spectral 30

- Technology FDM (Quad Extruders)

- Price $110,000

- Max. Extruder Temp. 500 ºC

- Max. Bed Temp. 300 ºC

- Max. Chamber Temp. 250 ºC

- Min. Resolution 5 microns

The Spectral 30 FDM 3D printer from Italian company 3ntr is an industrial high-temperature unit with four print nozzles.

The printer’s carbon printing plate with coating can be heated up to an impressive 300 °C and after the print is finished, the plate is simply removed with an easy magnetic locking mechanism. The Spectral 30 is able to process a wide variety of materials from ABS, PC, and PETG to Ultem, PEEK, and PPSU.

Other features include auto bed leveling, an integrated cooling unit, and a plugin that contains the profiles of all materials qualified for the device by the manufacturer. All you have to do is select the desired material or the desired material combination and the optimized settings for the 3ntr 3D printer are adopted. In addition, the Spectral has an automatic material recognition all 3ntr materials.

The Spectral 30 takes filament drying and storage seriously with the Vento filament drying module equipped with a 600W fan and space for 5-kg reels. The dryer has a monitor that detects the condensation point and, after the initial trying treatment, gradually reduces humidity and maintains it at 5%.

Essentium HSE 180 HT

- Technology FDM (IDEX)

- Price $149,000

- Max. Extruder Temp. 550 °C

- Max. Bed Temp. 100+ °C

- Max. Chamber Temp. 200 °C

- Min. Resolution 5 microns

Texas-based Essentium is another company specializing in high-temperature (HT) 3D printers. The company’s HSE 180 HT launched in 2019, the HSE 280i HT, and the new HSE 240 HT are open material platforms with the hardware to easily handle PEEK. The heated build chamber heats the part, not the entire chamber, with inferred energy that’s more tune-able and accurate, plus uses less overall energy, the company says.

Both the 280i and 240 models are independent dual extruder (IDEX) machines with multiple print modes, such as copy mode and support mode, while the HSE 180 HT printer is a single-head extrusion printer with one print mode. More impressive though, is the dual independent extruders (IDEX) that are actually independent on both the Y and X axis. This technology may not only speed up support printing, but offers multi-material printing for users to blend material properties at higher print speeds. This “true” IDEX, as the company calls it, enables the printer to create different parts at once, such as two sides of a mold, multi-material printer, or base material and dissolvable support material, in its massive build chamber (695 x 495 x 600 mm).

Setting Essentium printers apart from many others is the exceptional print speed, up to 500 mm/sec with all linear servo motors, and 1 m/sec travel speed.

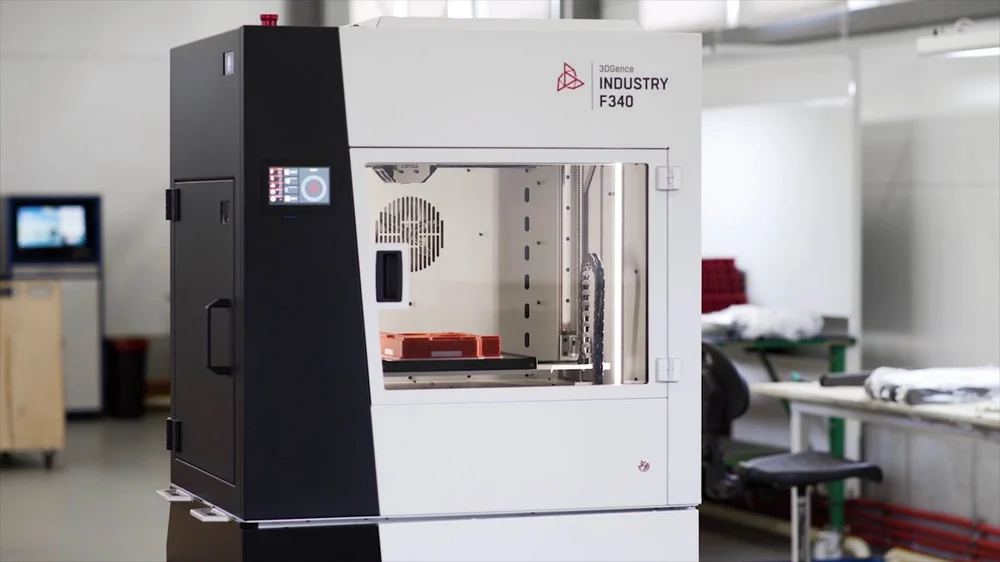

3DGence Industry F340

- Technology FDM (dual extruders)

- Price $30,000

- Max. Extruder Temp. 500 °C

- Max. Bed Temp. 160 °C

- Max. Chamber Temp. 85 °C

- Min. Resolution 40 microns

Polish industrial 3D printer manufacturer 3DGence offers three PEEK-enabled machines, the smaller Industry F340, the F421, and the F350.

One distinguishing feature of 3DGence machines are their swappable print-head modules that you can change depending on which engineering-grade material you want to use. This feature enables you to print with everything from PLA to PEEK on a single machine without having to clean out your print heads. The F340’s print chamber can maintain 85 °C while the F350 and F421 can get hotter, up to 140 °C and 180 °C respectively.

Like other industrial printers at this level, the F340 offers a filament dryer, automatic bed leveling, a heated ceramic build plate, and interconnectivity.

The F421 is a high-speed PEEK printer boasting a print speed up to 400 mm/s and 1 meter per second of travel time.

MiniFactory Ultra

- Technology FDM (Dual Extruders)

- Price $50,000

- Max. Extruder Temp. 480 °C

- Max. Bed Temp. 250 ºC

- Max. Chamber Temp. 250 ºC

- Min. Resolution 10 microns

MiniFactory – not to be confused with the 3D model platform MyMiniFactory – is a Finnish 3D printer manufacturer with a focus on industrial high-temperature 3D printers. Its Ultra printer has an open material system that can handle a range of thermoplastics and features automatic calibration, automatic and integrated post-processing, plus an exchangeable carbon filter.

The machine also features servo motors, ball screws, and linear guides to ensure large, dimensionally accurate, and reproducible prints. It takes the Ultra less than 30 minutes to heat and stabilize the printing chamber at 220 °C. The machine’s heated filament chamber also monitors the moisture and kicks on the heated drier when needed.

To make the printing process as simple as possible, data transfer works via USB in the miniFactory Ultra Basic model. Alternatively, you can choose a Security model, in which case the data transfer takes place via a WIFI or LAN connection according to your choice. MiniFactory says their technology is designed for daily industrial use and offers a warranty of up to five years.

Stratasys Fortus 450mc

- Technology FDM

- Price $160,000

- Max. Extruder Temp. 450 °C

- Max. Bed Temp. 250 °C

- Max. Chamber Temp. 350 °C

- Min. Resolution 130 microns

Stratasys industrial FDM 3D printers produce parts with PEKK, not PEEK by design. The folks at Stratasys offer their own PEKK material called Antero 800NA that they say is far easier to process than PEEK while offering much of the same benefits.

The Fortus 450mc and the F900 – the company’s two ultra high-temperature machines – are not open materials printers, yet (although that’s coming soon), so the Antero 800NA and two types of Ultem are your only choices in the PEAK family. That may not be the drawback it appears at first to be since Stratasys engineers have well-tested print perimeters for Antero on the Fortus 450mc and the larger F900 machine to ensure as close to error-free prints as possible.

Fortus 450mc is one of Stratasys’ most popular printers widely used for printing Nylon and often in a production environment. It comes with integrated GrabCAD software that enables you to print directly from CAD formats and fine-tune part performance and material use for greater cost efficiency.

The F900 is the company’s larger high-temperature machine available in three versions: the F900, the F900 AICS (designed for aircraft solutions), and the F900 Pro, which uses Ultem resin.

The F900 can be bolstered with an acceleration kit delivering faster print speeds.

Aon-M2+

- Technology FDM (IDEX)

- Price $50,000

- Max. Extruder Temp. 500 °C

- Max. Bed Temp. 200 °C

- Max. Chamber Temp. 135 °C

- Min. Resolution 1 micron

The large-volume, Canada-made Aon M2+ is the only printer by Aon3D and is designed for a range of applications including tooling, jigs and fixtures, end-use parts, and rapid prototyping.

The M2+ features independent dual extruders and is designed to print high-performance thermoplastics. It features an open-material environment, so it’s compatible with a wide range of material brands, including Solvay, Sabic, DSM, Infinite Material Solutions, and others, and comes with validated print profiles for each of them.

The M2+ features temperature control for consistent part properties, a new bed system that uses a heated vacuum build plate to enable faster cycle times and configurable adhesion properties via build sheet choices, and a completely new approach to automated bed calibration and leveling.

WASP 4070 TX

- Technology FDM

- Price –

- Max. Extruder Temp. 500 ºC

- Max. Bed Temp. 120 ºC

- Max. Chamber Temp. 250 ºC

- Min. Resolution 50 microns

WASP, an Italian manufacturer of delta 3D printers for everything from plastic to clay to construction materials, just released an updated version of its 4070 Tech, called the 4070 TX.

WASP says the new version further refines its PEEK process abilities with steel-core precision belts and all-metal double gear extruders that offer twice the grip and three times the force compared to common extruders.

The 4070 TX also features a liquid-cooled dual hotend system, filament dryer, and a HEPA filter.

SPECIALITY MEDICAL PEEK 3D PRINTERS

PEEK is a very useful material for medical applications because it is biocompatible, sterilizable, and is lightweight relative to its strength. It can be used for prostheses, implants, and other products.

Although most of the other printers in this guide can also be used to print PEEK items for medical or healthcare purposes, the following machines are specifically designed with this application in mind and boast the required medical device certifications to print implants.

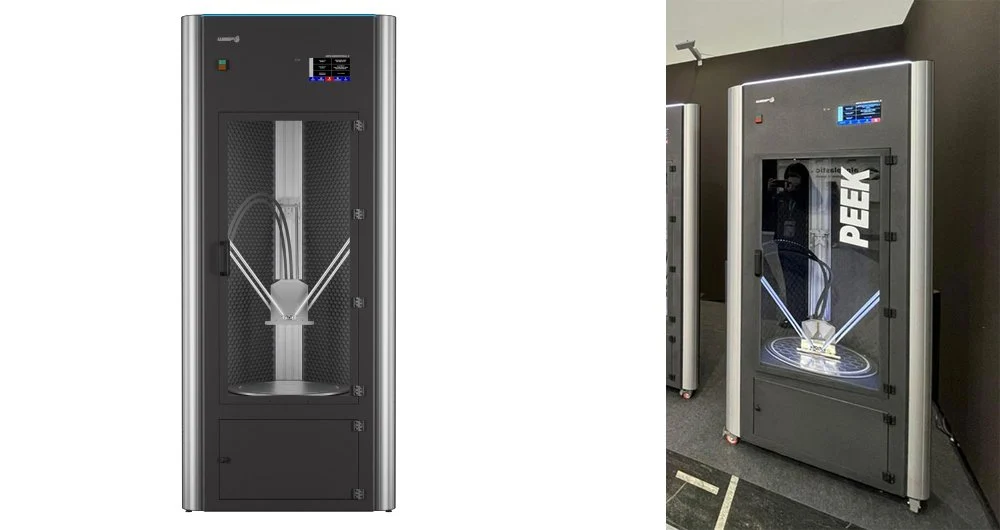

Apium M220

- Technology FDM

- Price –

- Max. Extruder Temp. 540 °C

- Max. Bed Temp. –

- Max. Chamber Temp. 280 ºC

- Min. Resolution –

German printer manufacturer Apium’s M220 is designed to manufacture medical products and implants using PEEK (the printer meets biocompatibility criteria to manufacture medical devices of up to Class III using PEEK). The company produces several varieties of PEEK materials and is also an open material platform.

It has a build volume of 130 x 130 x 120 mm and operates at less than 70 decibels.

Most important in the design is the machine’s hot-air filter system, which ensures a sterile printing environment. All of the parts on the M220 that come into contact with the filament are made of either PEEK, titanium, 316L steel, and PTFE, all of which are medically compatible.

The M220 has a camera system so you can remotely monitor prints. The printer comes with its own software which is designed to be easy to operate.

Kumovis R1

- Technology FDM

- Price –

- Max. Extruder Temp. 500 °C

- Max. Bed Temp. 300 °C

- Max. Chamber Temp. 250 °C

- Min. Resolution 200 microns

The Kumovis R1 is a PEEK 3D printer geared towards medical applications like implants.

Kumovis focused on the printer’s reproducible mechanics and dimensional accuracy to ensure parts fit as they should.

It has a printing speed of 100 to 3,000 mm per second, auto bed-leveling, and an open-materials system. The printer uses Hyperganic‘s Voxel-based slicing software and has Ethernet and USB connectivity.

It also has a patented temperature management system to homogeneously heat the build chamber and improve layer adhesion. You can turn the chamber into a clean room and get an optional HEPA filter upgrade to further ensure a clean environment. This will help prevent defects from particles that shouldn’t be in the chamber.

What’s more, the 3D printer is “clean room ready” for production in existing cleanroom environments and can be cleaned to medical standards. The printer is available through direct sales or as a subscription model. Build chamber fulfills ISO class 7 cleanroom requirements according to DIN EN ISO 14644.

What is PEEK?

The U.K.-based company Imperial Chemical Industries (today know as Victrex) introduced polyetheretherketone (PEEK) back in the 1980s. In its basic form, this material is a semi-crystalline, high purity polymer comprising repeating monomers of two ether groups and a ketone group.

PEEK belongs to the polyaryletherketone (PAEK) family of polymers that also includes PEKK (Polyetherketoneketone), but outshines the others because it can operate at higher temperatures and retain its excellent mechanical properties at continuous-use temperatures up to 240 °C (464 °F), allowing it to replace metal in severe end-use environments.

PEEK is one of the few plastics compatible with ultra-high vacuum applications, which makes it suitable for aerospace, automotive, and chemical industries.

Not all commercial PEEK products deliver the same level of performance. You’ll find PEEK filament and powder from a wide range of manufacturers, but be sure to check the technical specifications and data sheets to ensure you’re getting all of the PEEK qualities you require.

Speciality polymer makers, such as Solvay and Evonik, make PEEK especially for additive manufacturing and can advise you on the best ways to print their specific materials.

Do You Even Need PEEK?

PEEK has many compelling features, especially when it comes to producing functional prototypes and parts for regulated industries, but it is expensive and difficult to work with, so you make ask yourself: Do I really need to print with PEEK?

Let’s look at the pros and cons:

PROS

- Highly resistant to extreme temperatures up to 260°C (480°F), as well as corrosive fluids, gases, and high pressure

- Insoluble in common solvents, preventing it from hydrolysis and allowing it to be used without any degradation from high-pressure water or steam

- Lightweight: PEEK has an inherently low specific gravity of 1.3 g/cm3, less than half that of aluminum and one-sixth that of steel

- High self-lubrication ability and low friction

- Outstanding creep resistance

- Very little attrition

- Good dimensional stability

- Low flammability and little smoke emission when combusting

- Exceptional insulation properties

- Excellent sterilization resistance at high temperature

- Fully bio-compatible

- Food-safe and resistant to oils and animal fats

CONS

- Has to be processed at very high and consistent temperatures

- More expensive than most other filaments

- Low resistance to chlorine/bromide, concentrated sulfur, and nitric acids as well as Keteons and Nitrobenzene. PEEK also gets attacked by halogen and sodium, limiting its use in certain industry fields

- Low resistance to UV light

- PEEK filament it highly hygroscopic and must be stored carefully and dried before use

- PEEK is prone to warping and dimensional shift during printing if heat is not precisely controlled

Some of the warping, shrinkage, and difficulty printing with PEEK can be alleviated by combining PEEK with composite materials, such as glass fiber, graphite, or carbon fiber reinforcements. Post-print annealing can also boost your part qualities. PEEK’s low UV resistance can be worked around by adding a layer of pigment that consists of special soot particles. Carbon-filled grades provide improved UV stability and can be used in certain applications that require greater UV resistance.

Alternatives

If your part doesn’t require all the qualities of PEEK, consider these alternatives that are easier to print with and lower cost.

PEKK is also part of the same polyaryletherketone family of semicrystalline polymers as PEEK but requires a lower processing temperature and has a wider processing window, which makes it easier to print. PEKK is a bit more elastic than PEEK with good shock absorbance.

Ultem offers similar properties to PEEK but at a much lower cost and is also easier to process at lower temperatures. Ultem has weaker friction and wear properties than PEEK. Ultem is the trade name for polyetherimide (PEI).

Carbon-fiber reinforced Nylon doesn’t offer near the strength or chemical resistance of PEEK, but it is still an exceptionally strong material commonly used for jigs, fixtures, tools, and a host of other industrial applications.

What is PEEK Annealing & Why You Need It

Annealing is a heat-treatment and common post-processing method for PEEK that can improve its mechanical properties. However material scientists disagree about whether it’s essential for every part. It’s not a process unique to additive manufacturing as it’s used in injection-molded PEEK, too.

PEEK, as we mentioned, needs high heat to process, but it also needs the heat to change its very mechanical nature. How much heat and for how long your specific part needs isn’t also easy to calculate. Look to your printer manufacturer for print profiles and guidance, but certainly, you’re looking at a bit of experimentation in any case.

Truly understanding PEEK requires knowing about material science concepts of crystallinity and folded polymer chains and more nuances that we’re not going to dive into here. Just know that your printer may include an annealing setting or a list of annealing options you can follow, such as letting the component cool down at exactly 10°C per hour up to 140 °C or leaving the component at 200 °C for 1 hour for every millimeter of wall thickness.

If you want to learn more about annealing, the folks at Aon3D have a great blog post: PEEK – Best 3D Printing Temperatures to Maximize Crystallinity.

3D Printing Tips for PEEK

Now that you have a thorough overview of PEEK, maybe you want to start printing with it yourself. Here are a couple of basic tips and tricks to keep in mind when 3D printing with PEEK:

CONSISTENT TEMPERATURE

PEEK does not react well under fluctuating or unstable temperatures. Therefore, a printer with a heated chamber is strongly recommended, if not essential. To get the best results while 3D printing PEEK, keep the 3D printer in an environment that undergoes minimal temperature changes, and also away from solar radiation and heavily trafficked areas.

WATCH OUT FOR SPECKS

Sometimes, you may notice black specks when printing with PEEK. Although this may have a number of reasons, the most common explanation is the impurity of the printing material used or that the 3D printer is having trouble processing the required temperatures.

KEEP THE NOZZLE CLEAN

You should always clean the nozzle after the printing process is completed. All leftover material should be removed from the nozzle, or it may become blocked and eventually also lead to specking (mentioned above).

WATCH OUT FOR FAILED CRYSTALLIZATION

Sometimes, when printing with PEEK materials, improper crystallization may occur. If parts of the print vary in color, such as a brownish discoloration as opposed to a default beige color, this could indicate improper crystallization. It can be caused by a fluctuating temperature during the print process.

STORE FILAMENT IN A DRY PLACE

When you are not 3D printing with PEEK, you should keep the material stored in a cool, dry, and dark place until you use it again. By doing this, you will preserve the quality of the material and ensure that you will achieve optimal results.

PEEK Parts On-Demand

Not ready to take the plunge into buying your own 3D printer for PEEK parts? On-demand additive manufacturing is available for your PEEK and PEKK needs. If you’re new to this material, or to additive manufacturing, experimenting with a few parts printed at a contract manufacturer may be the best way to prove your concept.

Many of the larger on-demand printing services offer PEEK printing and you may also find it as an option alongside injection molding from manufacturers who specialize in high-temperature polymers.

FacFox, the 3D printing marketplace, provides instant quotes on your PEEK part from a range of manufacturers.