TPE vs TPU filament. Find out the differences between these two flexible filaments, and learn how to print with TPE and TPU!

It’s Good to Be Flexible

TPE and TPU flexible filaments are both thermoplastic elastomers that allow a print to stretch or bend easily. Before we get into more details about these two types of filament, let’s talk about flexible filaments in general, and why they’re used.

There are several reasons why you’d want a print to have flexible or rubbery properties, such as vibration dampening and shock absorption, high impact strength, and good resistance to tearing, abrasion, chemicals, and high or low temperatures.

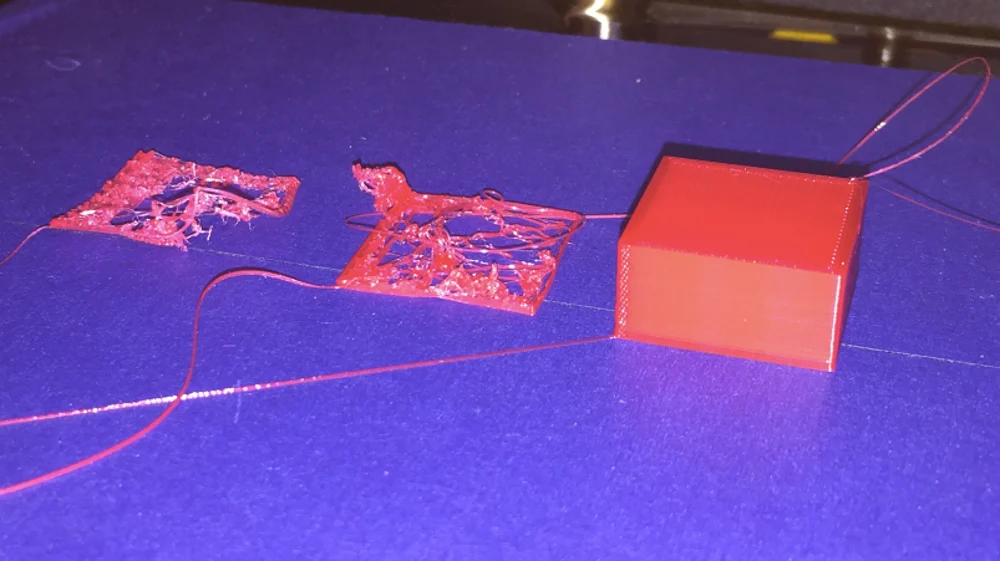

With all those pluses, it should be noted that flexible filaments are not always so easy to print with. In general, the softer and more bendable the material, the trickier it can be to print.

If you have something in mind that you want to print, but would like to remove any potential hassle, considering using FacFox‘s 3D Printing Service.

Now, let’s delve into more about TPE and TPU filaments and clear up the differences between them. We’ll also go over the best practices for printing with them and leave with you with a few prints to try yourself!

The Two TPs

TPE

TPE stands for thermoplastic elastomer. It’s a blend of hard plastic and soft rubber, so it has both thermoplastic and elastic properties. TPE covers a wide range of flexible materials, including thermoplastic polyurethane (TPU), thermoplastic co-polyester (TCP), thermoplastic polyamide (TPA).

TPU

TPU stands for thermoplastic polyurethane. It’s the most common type of TPE and is on the more rigid side of flexible filaments.

Clear Up the Confusion

Since the terms of TPE and TPU are often interchanged loosely, it’s worthwhile to set the record straight.

- TPE is known as soft filament and has been available for several years. TPU, on the other hand, has only recently come on the scene, so its newer to the market.

- TPE is a non-specific term for flexible filament, while TPU filament refers to the more rigid-flexible filament.

Now that we know the basics of these two filaments, let’s get into more details about their differences.

The Same but Different

How TPE and TPU are defined is by their hardness, which measures a material’s resistance to surface deformation. As we know, TPU is harder than TPE, and TPU’s Shore hardness is between 60A and 55D, with a high elastic range (typically from 600-700%).

Logically, TPE has a wider range of hardness than TPU. The variation in chemical formulation of TPE means some types of TPE are partially hard and suitable for something like a car tire, while other types are very rubbery, like a rubber band.

Compared to TPE filament, TPU filament exhibits greater rigidity, which isn’t to be confused with hardness. Rigidity measures the ability of a material to bend, indicating the tendency of a material to return to its original form after being subjected to a force.

Other differences include that a TPU print will be heavier, because TPU is denser than other TPEs. TPU also has a smooth finish, while TPEs usually have a more rubbery texture. TPU has better resistance to abrasion than most TPEs, and TPU shrinks less than other TPEs.

Now that we know all about their differences, let’s take a look at how best to print with them.

Printing Settings & Tips

Printing With TPE

TPE filament can be hard to print with due to its elasticity. It’s recommended to print with the following settings:

- Extruder temperature: 210-260 ºC

- Bed temperature: Unheated-110 ºC

- Print speed: 5-30 mm/s

If printing goes too fast, it could easily result in a jam. TPE works better with a direct drive extruder, so be especially careful if you have a Bowden extruder.

Some popular brands of TPE filament include eSun TPE (around $42/kg), MatterHackers Pro Series TPE (around $55/0.5kg), and 3DXFlex TPE (around $68/0.5kg).

Printing With TPU

The good news is that TPU filament is easier to print than TPE, because it’s relatively stiffer, but compared to rigid filaments like PLA, TPU filament is still tricky. It’s recommended to print with the following settings:

- Extruder temperature: 210-230 ºC

- Bed temperature: Unheated-60 ºC

- Print speed: 5-30 mm/s

It’s very important to slow down the extrusion speed and retraction movement, in order to optimize the printing process.

Some popular brands of TPU filament include Kodak Flex TPU (around $50/0.75kg), Ultimaker TPU (around $70/0.75kg), MatterHackers Build Series TPU (around $45/kg), Polymaker PolyFlex (around $55/0.75kg), and the well-known NinjaTek (around$55/0.5kg).

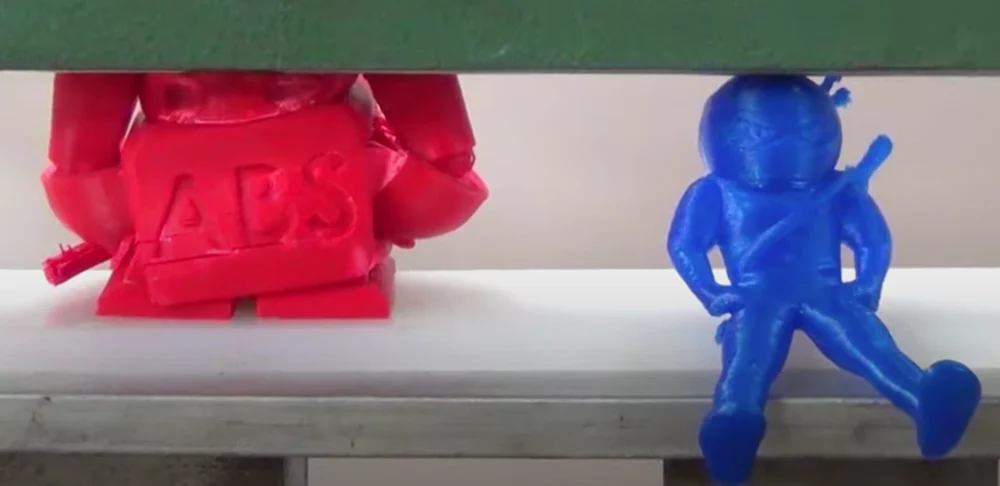

Give It a Try

Now we know that TPU is a type of TPE. Other TPEs are usually softer than TPU, which means TPU is easier to print. In general, if you want heavier, tougher, and more durable objects, choose TPU filament, but for lighter, softer, and more flexible prints, choose TPE filament.

Some cool models to try out with these two filaments are a phone case, bike handle, and pen grip.

Source: https://all3dp.com/2/tpe-vs-tpu-flexible-filament-the-differences/