Selective laser sintering is a 3D printing technology that uses a laser to fuse a thermoplastic powder to build parts. We’ll explain how this technology works, discuss its pros and cons, and point out where it’s utilized.

What is SLS and How Does It Work?

Selective laser sintering (SLS) 3D printers make use of a laser and a thermoplastic polymer powder to build parts. Because of the high power laser, it’s generally considered more complicated than both FDM and SLA.

SLS 3D printers consist of a powder bin, a build platform, a powder re-coater, a laser (either CO2, diode, or fiber), a set of galvanometers, a set of heaters, and a powder feeder.

Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. The bin is then placed into the machine, where the heating stage begins. Before printing, heaters are used to get the powder to a temperature just below its melting point.

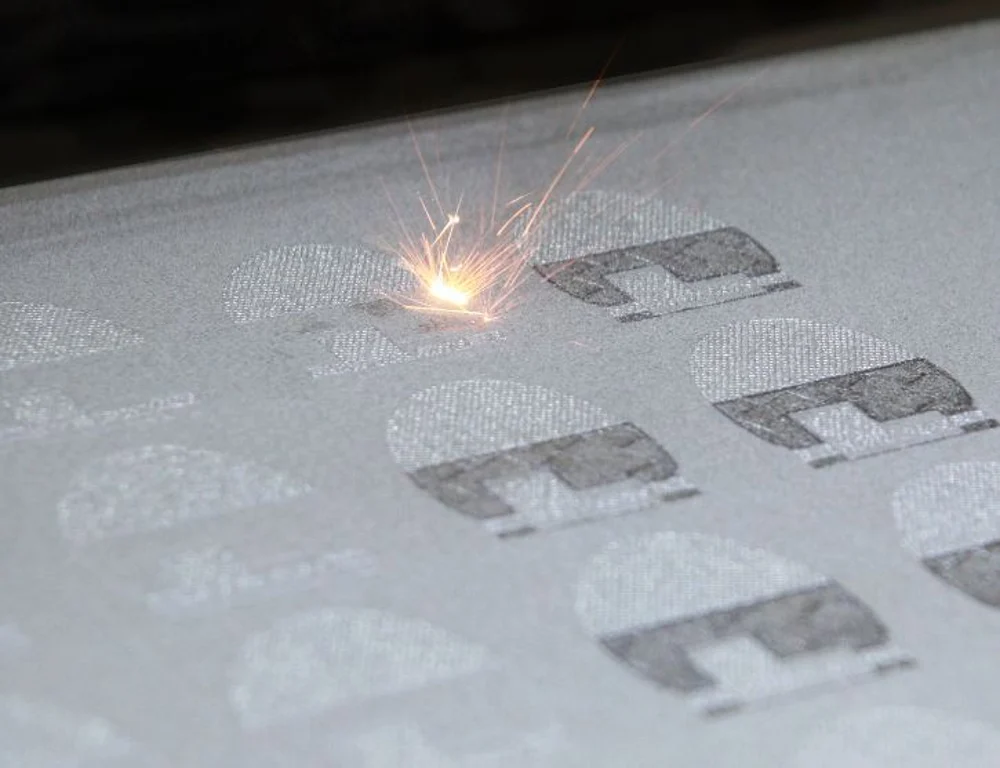

The actual printing starts with the re-coater depositing a single layer of powder onto the build platform. That’s where the CO2 laser comes into play. The laser’s role is to selectively induce fusion between particles to form a solid at specific locations.

Galvanometers are used to navigate the laser beam to a specific point on the build platform. If you don’t know what galvanometers are, think of them as tiny mirrors.

The laser moves along a “point-to-point” pattern, solidifying the whole cross-sectional area of a layer. After the layer is complete, the re-coater deposits a new layer of powder and the build platform moves down one layer in height. The process is then repeated until the part is complete.

Pros & Cons

Just as with any other 3D printing technology, SLS also has its pros and cons. The biggest advantage of SLS is that there’s no need for additional support material, regardless of the part’s geometry.

As parts are built inside the powder bin, the non-sintered powder acts as a support material to the printed part. After the part has been printed, it’s left with no markings of the support material on its surface. The powder need only be brushed away.

Apart from this unique advantage, there are a few more. Because parts are built by a laser, which solidifies a cross-sectional area of each part, multiple parts can easily be printed at once. This makes SLS ideal for small manufacturing runs. The goal with SLS printers is to fill the build area with as many prints as possible so as to reduce the non-sintered waste powder.

Having said that, it’s worth mentioning that, generally speaking, 50% of the non-sintered powder can be recycled.

Unlike FDM, parts printed with an SLS printer can’t be used right after the print process is complete. That’s because parts must cool down, which can take a long time.

The most significant disadvantage of SLS is that it requires high-end technology and a lot of power. As such, it’s not quite ready to hit the consumer market.

SLS For Small Business

SLS 3D printers are ideal for small manufacturing runs as the goal of every SLS 3D print is to produce as many parts at once. This both improves the speed of manufacturing and reduces the waste of non-sintered and non-recyclable powder.

To give you an example, take a look at the above picture. What you see is a simple bike chain hook, which allows a cyclist to put the chain back on their bike without getting their hands dirty.

This particular brand, called “Rehook”, is made entirely on SLS printers. The technology can easily produce multiple Rehooks per print, and the strength of the polymer is enough for the application.

SLS vs SLA

In case you feel you don’t yet know which to choose between SLA and SLS, click here for a detailed article. It points out the main differences between the two technologies and which of the two are the best for what.

Source: https://all3dp.com/2/selective-laser-sintering-sls-3d-printing-simply-explained/