After the 1980s, all parts of the world began to understand and develop 3D printing technology, which promoted the rapid application of 3D printing in the fields of construction, medical, education and other fields.

In the aerospace field, 3D printing is very suitable for the design and manufacture of high-end, precision parts, so its value in the aerospace field has received support from many parties.

After long-term development, the market for additive manufacturing is gradually growing. The main promoters include GE, Airbus, Boeing, Safran, and GKN. They have determined the value of 3D printing in the aerospace industry:

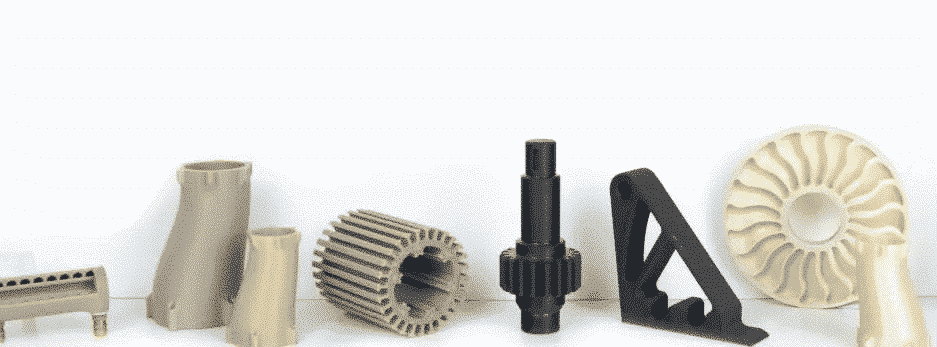

Low-volume production

For the aerospace and defense industries, 3D printing has become one of its ideal choices. This technology can create products with complex geometric without the need to invest in expensive tools and equipment. This provides a cost-effective process for producing low-volume parts.

Lightweight design

In addition to aerodynamics and engine performance, weight is one of the most important considerations in aircraft design. Reducing the weight of the aircraft can reduce its carbon dioxide emissions, fuel consumption, and payload.

This is the advantage of 3D printing: the technology is an ideal solution for manufacturing lightweight components, which can save a lot of fuel.

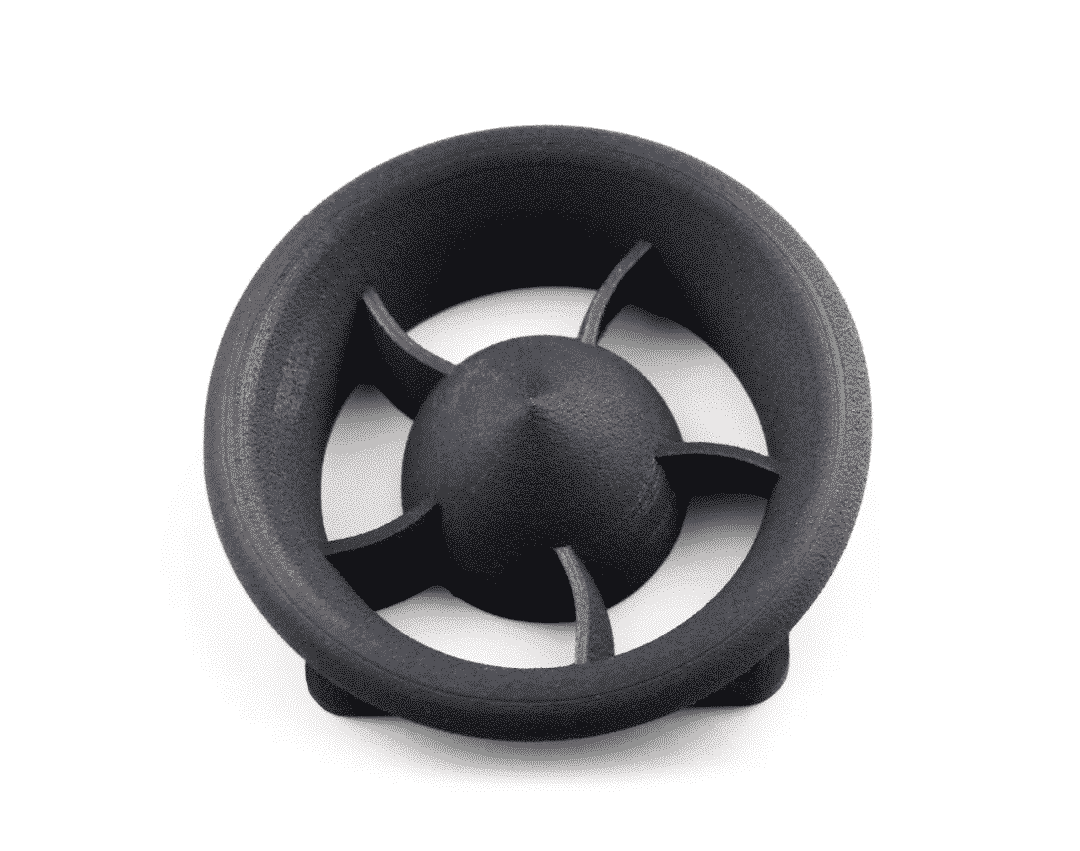

Integrate parts into one

One of the main advantages of 3D printing is part consolidation: the ability to integrate multiple parts into a single part. Reduce the time required and simplify the assembly and maintenance process.

Maintenance and repair

The average life of an aircraft can be between 20 and 30 years, during which maintenance, repair, and overhaul (MRO) become an important issue in the industry. 3D printing can fastly produce spare parts and fixing tools, which can greatly release labor reliance.