Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties.

While most elastomers are thermosets, thermoplastics are in contrast relatively easy to use in manufacturing, for example, by injection molding. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials.

So, what is TPE usually used for? We summarized four kinds of application for you.

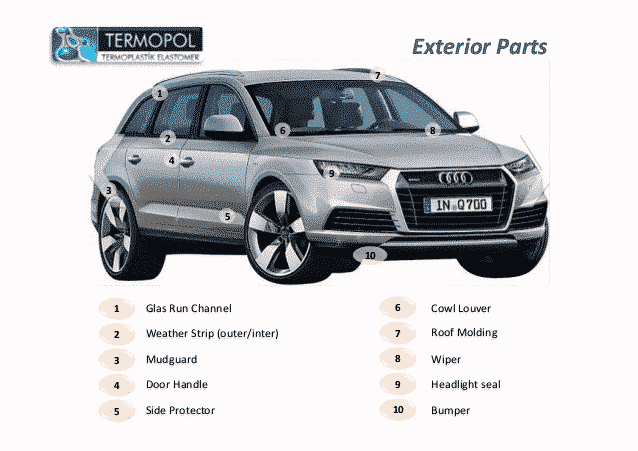

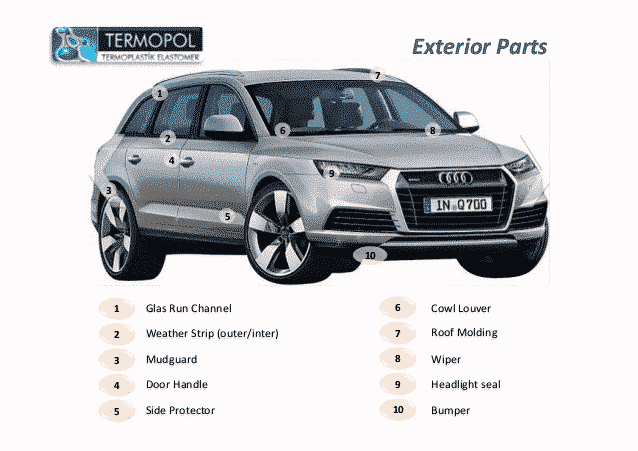

Car Accessories

TPE can withstand relatively high and low temperatures (-50 ~ 100 ℃). It has good fluidity and excellent flexibility, and is oil resistant and eco-friendly. In a word, it meets customers’ high requirements for weatherability.

- Application examples: tire, bumpers, handles, steering wheels, dust covers, etc.

Dual and Multi-material Applications

TPE is very popular in multi-material applications. A product can be coated with a layer of TPE, which makes the product more modern and soft. TPE offers a good sense of touch, excellent physical properties, that’s why it’s so popular among consumers.

When TPE and other materials are co-molded, it can firmly bond ABS, PC, PA, PP, PS and other plastics. TPE / TPR can adjust the physical properties and hardness of multi-material products, enable designers use their unlimited design inspiration.

- Application cases: tool handles, sports equipment, wheels, electronics, daily necessities, etc.

Extruded products

TPE has good UV resistance and chemical resistance. When it’s applied in the simple extrusion process, it becomes a new ideal material to replace traditional rubber and PVC.

- Application cases: headphone cable, USB cable, cable, building sealing strip, door and window strip, anti-collision buffer tape, etc.

Extra-soft Products

TPE meets human skin contact hygiene requirements and is considered a “green” material. High transparency, high tensile strength, high expansion and flexible touch, TPE is highly sought after by consumers.

- Application cases: Extra-soft toys, women’s breast pads, adult products, etc.

Conclusion

TPE is also a hot filament in FDM and SLS 3D printing. All its traditional applications are also feasible in 3D printing. Besides, 3D printed TPE products are used in prototyping and verification.

TPE is flexible in physical property, and 3D printing is flexible to realize your imagination.