If your 3D printer seems small, you’re right. Check out the Vulcan II, a beast of a machine that 3D prints beautiful homes in less than a day.

It’s Concrete, Jim

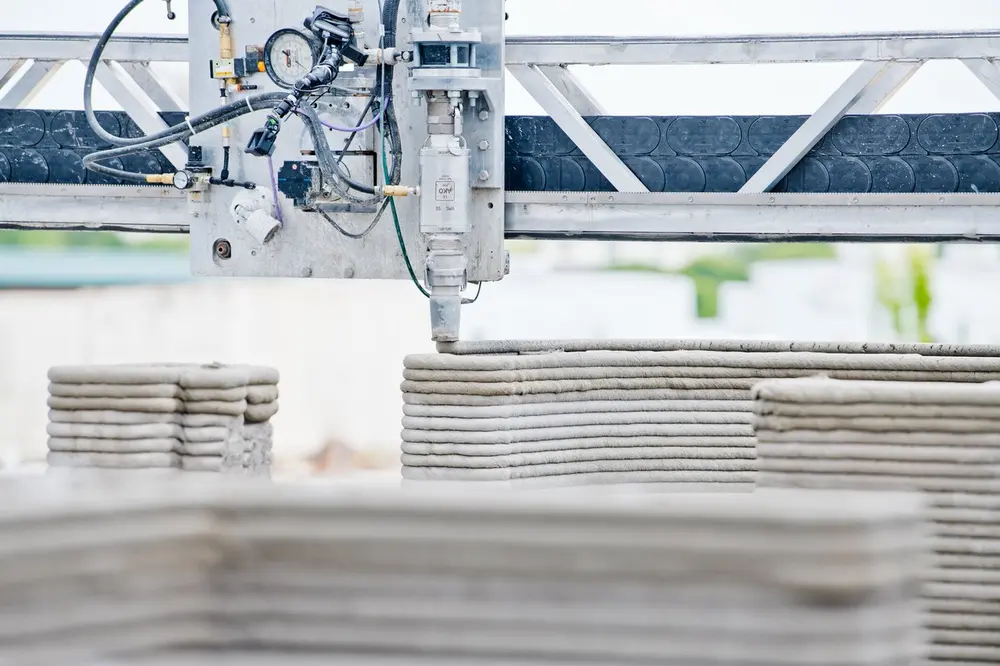

3D printing with concrete has come a long way from being just a theoretical idea. Start-ups and companies around the globe have disrupted this century-old industry by 3D printing concrete structures, both for living and commercial use. In this article, we’re going to focus on one such company, Icon, which made the Vulcan II and is bringing 3D printed construction technology to the open market.

Icon is a Texas-based start-up that began around 2017. They’re re-imagining the way homes can be made, with the mission of making the process more affordable, sustainable, and available. With that, they’ve taken some great steps forward, including being the first company in the United States to get a building permit to 3D print a home. They also won an award from NASA for their design of a 3D printed home to be built on Mars.

Back on Earth, in 2018, they unveiled their own concrete 3D printer, the Vulcan, and the home it printed (in the image above). A year later, they came out with the Vulcan II. It features a clean, sleek design and the ability to print a house of 600 to 800 square feet in under 24 hours, and for less than $4,000.

Let’s take a closer look at why we need these concrete machines and what this second generation Vulcan printer has to offer.

Why Print Buildings

Before we get into the Vulcan 3D printer, it might not be a bad idea to discuss why 3D printing technology is being used at all in the construction industry, specifically with building residences.

The two most important factors when you’re talking about home building is time and money. It’s well known that 3D printing homes is significantly faster than when built with manual labor. Icon boasts that it can print tiny homes in less than 24 hours and larger homes in under three days. When comparing the time it takes to 3D print a house, Icon is in the lead. And when it comes to money, 3D printing has the great advantage of needing just a small team to supervise and operate the printer. In other words, fewer people, lower cost.

Additionally, it’s not news that both natural disasters and political upheaval have displaced and continue to displace millions of peoples all over the world. While not limited to developing nations, they’re often the hardest hit.

Refugees are a prime example of this. When they arrive at a new, often temporary place, tents are the norm for their shelter. If 3D printing becomes involved, homes could be made from concrete, which is safer and better insulated than tents or other semi-permanent structures, and can be printed quickly and cheaply.

In line with their mission statement, Icon has partnered up with the global housing non-profit New Story and the Mexican social housing enterprise Echale to build 50 homes in rural Mexico. In their own backyard, Icon also has a partnership with Mobile Loaves and Fishes to build homes for the homeless in Austin. To learn more, Icon put out a great video that shows more about this local project.

Now, let’s learn more about the amazing machine that made all this possible.

Meet the Machine

Printer Specs

- Printer height: 8.5 feet

- Printer width: 28 feet

- Weight: 3,800 pounds

- Print speed: 5 to 7 inches per minute

- Print bead size: 1 inch tall by 2 inches wide

- Print area capability: As large as the space allows

- Material: Lavacrete (proprietary)

- Water requirements: 2 gallons per minute

- Interface: Integrated tablet

Using the Machine

Icon’s Vulcan II boasts many great features, such as only requiring four to six people on-site to operate and oversee the entire process. In terms of interface, a built-in CAD tool and print planning platform translates floor plans into print jobs within minutes and also provides pre-print visualization.

All components are IP66-certified, which means they perform well under all weather conditions. Additionally, the printed house sits on top of an ultra reinforced foundation made to withstand any seismic activity.

The Vulcan II prints exclusively with Lavacrete, which was developed by Icon to have the properties of concrete but the stiffness required to be extruded from a nozzle. In other words, Lavacrete holds its shape once it’s extruded. Icon has also developed a material-handling and -delivery system for Lavacrete called Magma, which makes Lavacrete on-demand with the push of a button and sends it to the print head, ready for printing.

Unfortunately, the Vulcan II has yet to enter the commercial space and is still being tested in-house. That said, Icon has set a target of sometime in 2020 to start shipping the Vulcan II, and you can be sure we’ll keep an eye out when it enters the market.

Road Ahead

Opportunities

Globally, there are currently only a handful of manufacturers who are able to 3D print buildings. Companies such as US-based Apis Cor, Italian 3D Wasp, and Danish COBOD are building similar solutions to Icon’s Vulcan, using layer-by-layer concrete deposition techniques with a giant gantry or arm.

One key factor that’s keeping Icon at the forefront of this technology is that they’re not only using their printers to build homes; they’re also selling their technologies to multiply their presence in the industry. Icon has made their machines easy to use and automated the entire process.

Challenges

While the Vulcan II is far ahead in integrating advanced automation into the 3D printing construction industry, there are still some major gaps that remain.

One is that the maximum print height of the Vulcan II is 8.5 feet. Since that isn’t so high, buildings may need some additional prefabricated parts to complete the construction, especially when it comes to roofing.

Along those same lines, the Vulcan II can currently only print single-story houses. And unfortunately, there’s a great need for multi-story buildings, especially when it comes to affordable housing.

Homes of the Future?

3D printing buildings has come a long way from just being a concept and computer model. It’s now a reality where communities have taken safe haven within them. However, there’s still a long way to go before this construction technique becomes the norm, but the technology is very promising. We know we’re looking forward to seeing more from the Vulcan II!

Source: Vulcan II/2 3D Printer: All You Need to Know | All3DP