Let’s use 3D scanning and vase mode 3D printing to achieve a real tree texture effect for functional or decorative items. There are many trees that carry a piece of history or sentimental value for someone. It may be an oak, which can be hugged by five or more people. This tree outlived quite a few generations and maybe under protection of local conservationists. It could be a maple that holds a swing, or a pine with awesome cones. Even a birch 3D scanned texture can be transferred to an object. At the same time, the vase mode 3D printing is a brilliant time-saving technique for such tasks.

Vase Mode 3D Printing – Simplify3D, Cura and Prusa Slicer Settings

When 3D printing in vase mode, the machine’s extruder is set to move in a corkscrew, or spiral, mode. There are no retractions. Simplify3D, Cura and Prusa slicer software all have such mode settings under different names, please find the screenshots below.

Vase Mode General Settings

- Layer Height: 0.1 – 0.3

- Layer Width – Auto or as wide as possible.

- Bottom Layers: 2-3 – The bigger base areas take longer to 3D print.

- Top Solid Layers: 0 – Check the preview mode to make sure there is NO top.

- Perimeter Shells: 1

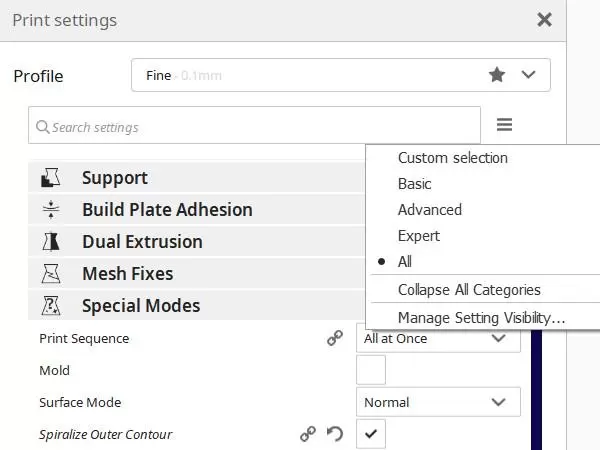

Cura Vase Mode 3D Printing – Spiralyze Outline Contour

(Image: Cura Software Screenshot)

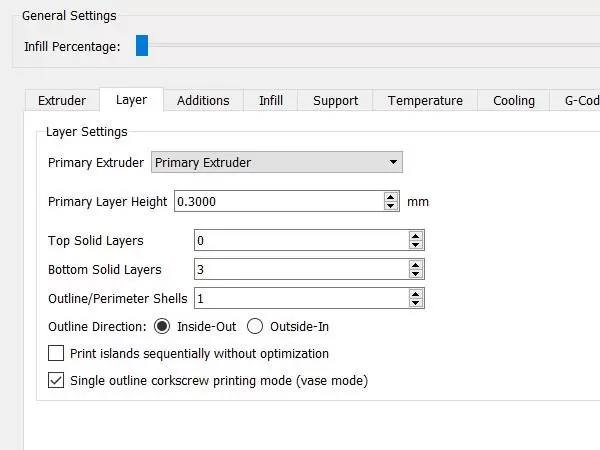

Simplify3D Vase Mode 3D Printing – Single Outline Corkscrew

(Image: Simplify3D Software Screenshot)

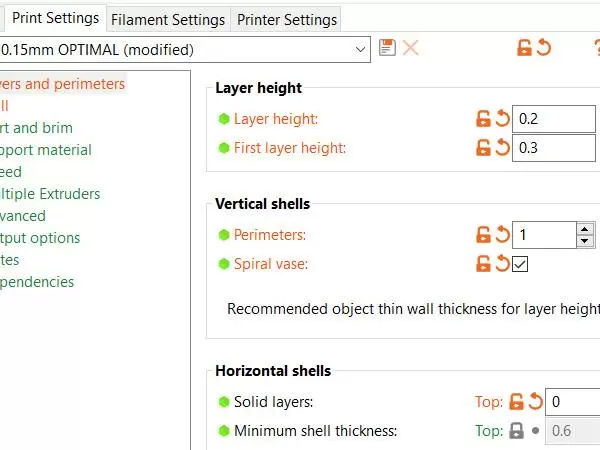

PrusaSlicer Vase Mode 3D Printing – Spiral Vase

(Image: PrusaSlicer Software Screenshot)

Big objects are 3D printed significantly quicker if 3D printed in the vase mode. 150 mm tall vase can be 3D printed in 3 hours using just 60g of the filament. Objects, that are 3D printed in vase mode on desktop 3D printers, are fragile, therefore it is hard to find functional usage for them. Check the ideas and the results we achieved for the 3D scanned tree textured vases.

3D Scanned Tree – Oak, Birch, and Pine Texture

On our website, you can find a few blogs about photogrammetry (photoscan). Using just a mobile phone camera we 3D scanned an oak, a birch, and a pine. Initially, we used various tree textures for 3D printed coasters. Functional 3D printed coasters can serve for a long time and be an inspirational object on any table. Only when we tried to use the same textures on something larger in size, the idea to try the vase mode came up. The result is awesome.

Vase Mode Ideas

These vases can be slightly modified depending on what you wish to achieve in the end. In 3D design software, the top or the bottom side can be widened if needed, without affecting the texture much.

Lamp Shades – As the result, we 3D printed an awesome “cone shaped” lamp shade using scanned birch tree texture and an ” upside-down cone shaped” 3D scanned pine tree texture.

Disclaimer: We are not the electricians and cannot say what is the safe size, shape, or material for such a task. It may turn out that objects, 3D printed in PLA, may deform and melt, and cause a hazard. Therefore, other materials, with higher temperature features and fire-resistance qualities, may be better suited for the lighting applications.

Flower Pots – We are testing a few of them on terrace. These objects are not waterproof, micro holes do appear on them, and the water seeps through. The vase mode technique is not suitable/ready for waterproof 3D printing. For the plant pots, a few holes will need to be made, depending on a flower/plant type.

3D Printed in a Wood Filament

We used wood filament for this type of prints. Both, the tree texture coasters and the vases, have a natural feel, and they smell well from the beginning. Also, such objects can be stained by varnish adding the desired finish. Check the detailed wood filament review with 3D printing tips & tricks.

Featured objects were 3D printed in the known filament brands available on Amazon, namely, in Fillamentum Timberfill, BQ Wood, and Amolen Wood.

In the YouTube video below we briefly show the way to transfer the texture of any tree to a 3D printable object. It is possible to achieve this using just a mobile phone camera, photogrammetry software like Meshroom, and 3D design software like Blender3D for texture cleaning for further editing.

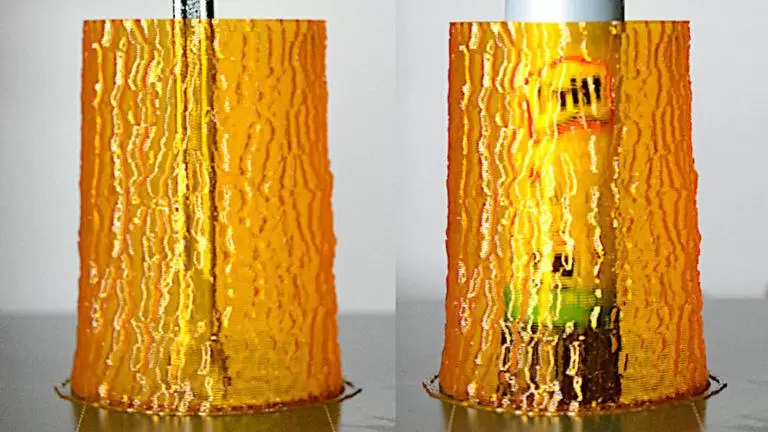

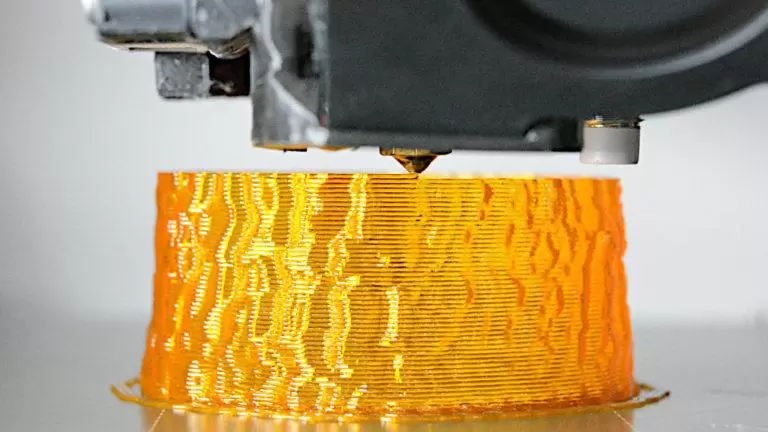

3D Printed in Flexible Filament with a 0.8mm Nozzle

We achieved the shiniest result when 3D printed in a vase mode with a 0.8mm nozzle at 230°C. The filament fused so well that the walls came out transparent. It is possible to see the object through the walls.

The 0.8mm nozzle and high temperature allowed to fuse the layers so well that all 3D scanned tree trunk vases could hold water. The objects are not completely waterproof, and after some time water will find its way out, but it may take hours or days.

Source: Vase Mode 3D Printing – Cura, Simplify3D, PrusaSlicer Settings (3dwithus.com)