Oakley, a sports eyewear brand, is using HP’s full-color Multi Jet Fusion technology to produce functional prototypes. The company has been providing high-performance eyewear products to the sports industry for more than 40 years, and for the first time in 1992 adopted 3D printing into its design verification process.

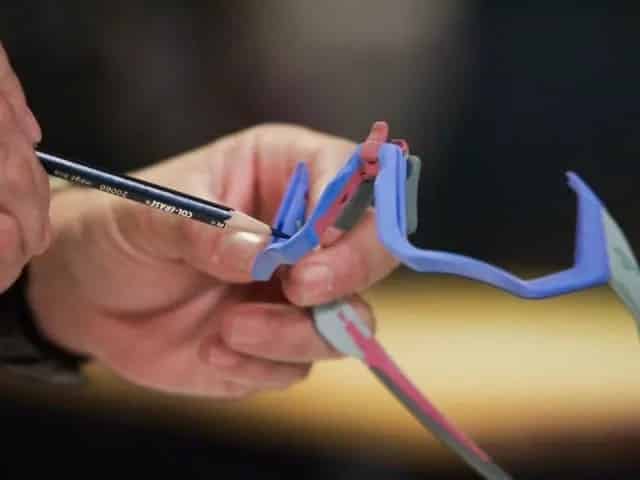

In 2018, the company began to prototype sunglasses, helmets, etc. using the color capabilities provided by the HP 580 machine. Oakley designers said that after using HP’s full-color 3D printing technology, they have been enjoying the rich details of the model and can print parts and start testing within 24 hours.

In these tests, Oakley emphasized the importance of using HP’s lightweight and durable material High Reusability CB PA 12 in replicating the final production part. Another benefit of this machine is its large size, which means larger volumes and large printed parts.

Oakley Design Director Nicolas Garfias said: “World-class athletes rely on Oakley for the highest level of competition. With HP ’s breakthrough 3D printing technology, we can not only accelerate the design of production but also rethink the way products are manufactured, pushing the boundaries of athletic performance to new heights. ”

Jeff Fawcett, HP 3D Printing Product Manager, added: “Oakley has the highest design standards, and our innovative 3D printing technology can help them provide a new experience for millions of athletes around the world, transforming the way of design and manufacturing of consumer products worldwide. “