SLA printer resin can affect you and the environment. Learn more about resin printer fumes and how to keep yourself and the planet safe.

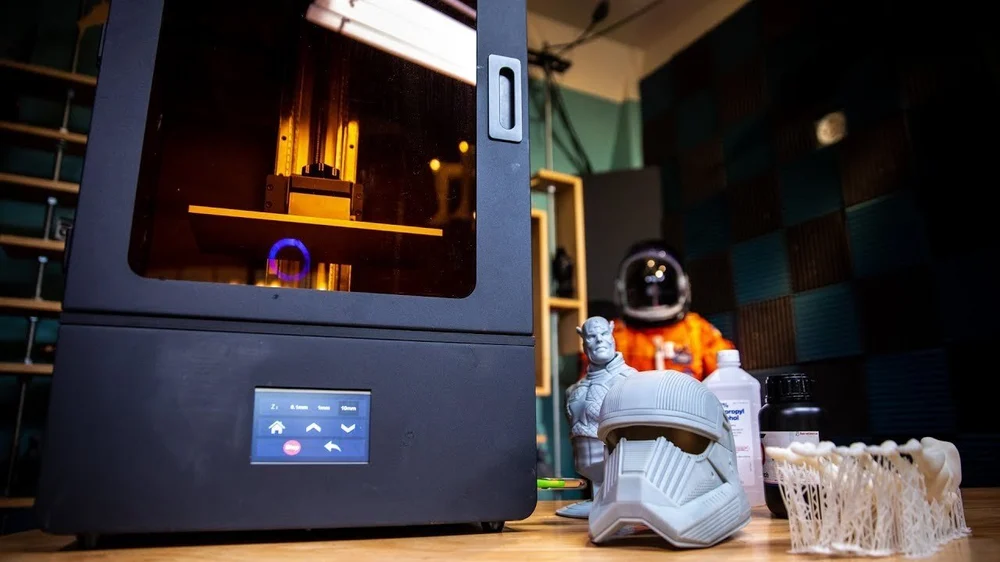

SLA Is Special

Stereolithography, commonly referred to as SLA, is a type of additive manufacturing that uses photochemical techniques to 3D print objects. More specifically, concentrated UV light is directed at resin to link molecules together, which ultimately forms the shape of a print, layer by layer.

Unlike FDM, SLA’s raw material isn’t spools of solid, thread-like filament. Instead, it uses liquid resins, which are photosensitive mixtures of monomers and oligomers – short chains of carbon molecules that are combined into longer chains during the photochemical process to become hardened plastic.

Unfortunately, the chemical nature of resin is more toxic than FDM filaments. But don’t worry – scientists have discovered a few simple ways to combat this.

Read on to learn in what way resin is toxic and to discover how to make your SLA 3D printing safer for both you and the environment. Finally, we’ll recommend a few eco-friendly resins that you can try for yourself.

Know Your Enemy

So, how exactly is resin toxic? Well, because of its material properties and the way it’s treated in the SLA printing process, resin releases irritants and pollutants. Here are a few things to think about when working with SLA resin:

- Irritating to the skin and respiratory system: You should never expose your bare skin to the liquid chemicals of 3D printing resin. They can create contact dermatitis, which is a surface rash that could develop into an allergy if you expose yourself to resin for long periods of time. Resins also naturally give off fumes, and unless you work in a well-ventilated area, molecules from the fumes will get into your lungs and cause irritation there, too.

- Harmful when exposed to eyes or ingested: Never let resin near or into your eyes or mouth unless they’re specifically marked as non-toxic. (And even then, it’s probably not a good idea.) Standard resin for 3D printing isn’t rated eye or food-safe and can quickly cause permanent harm if exposed to these areas of your body.

- Toxic to the environment, especially aquatic ecosystems: Tragically, several independent scientific studies have come out that show molecules in printer resin can attach themselves to the central nervous systems of fish and other aquatic animals, breaking down their neurological processes and killing them. Nanoparticles are another big concern because they’re microscopic and an unavoidable byproduct of 3D printing. As 3D becomes more popular and widespread, we’re learning more and more about the extent of their impact on our environment.

- Unstable curing process: In the final step of SLA 3D printing, an ultraviolet light (or sunlight if available) is used to cure (fully harden) the print. Though a necessary step, it’s dangerous to leave objects in the light for too long because excessive exposure can cause prints to break down.

Protecting Yourself

Despite its toxicity, there are ways to make sure you stay safe when printing with resin. Here are a few ways to protect yourself while working:

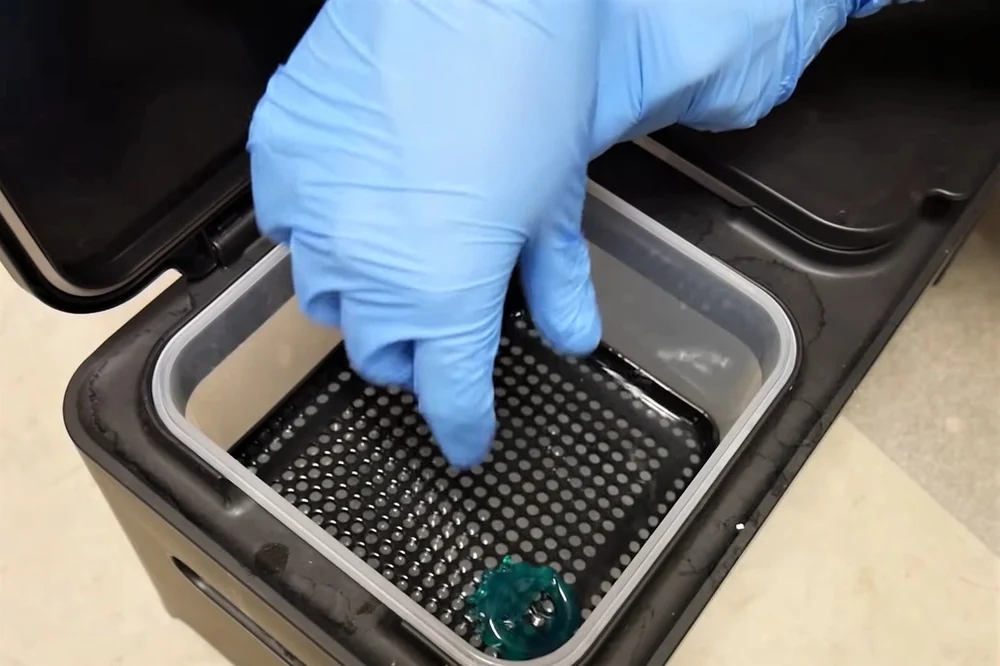

- Wear protective goggles and nitrile gloves whenever you handle SLA resin: The easiest and cheapest way to keep your body from coming into contact with irritating chemicals is to wear physical barriers. It’s certainly not necessary to don a full hazmat suit every time you want to print with resin, but full-coverage nitrile gloves and eye protection will go a long way to keep you safe.

- Work in a ventilated area: If resin fumes can escape from the work area, they won’t stick around and enter your throat or lungs. The best-case scenario is to work under or near a ventilation hood, which should be standard operating procedure if you’re working in an industrial or scientific space. But even if you’re a home hobbyist, it’s a good idea to set up your workspace near a window that can open, buy a ventilation fan, or otherwise make sure you’re not working in a sealed environment, where the fumes have nowhere to go but into your lungs.

- Read all safety and operating instructions beforehand: We hope this is a no-brainer for all 3D printing materials and processes, but it’s especially vital when you’re working with toxic chemicals such as SLA resins. Resin containers themselves will give you details on specific toxicity and how to avoid activating it. They should also give you an expiration date and recommended storage temperature. Read all of these warnings and instructions several times before you print, and look up anything you don’t understand. That way you’re fully prepared to easily and safely print.

- Cure any resin you plan to dispose of: As briefly mentioned above, one way to transform liquid resin from toxic to harmless is to cure it with UV light. If you have a batch of liquid resin that you’re planning to throw out, expose it to the sun or an artificial UV source until it’s completely hardened. Once it’s dry, the plastic is harmless to touch. That said, remember that too much exposure will eventually break the material down.

Protecting the Environment

As we know, if handled improperly, resin can be harmful to the user. This is true for the environment, as well, so make sure you handle exposure and disposal of resin with extreme care. Here are a few tips on how to keep SLA pollution to a minimum.

- Thoroughly clean your work area: As with any manufacturing process, keeping a clean workplace limits toxic exposure for both you and your environment. First, use soap and water to clean up any spills, then wipe it down with isopropyl alcohol. (Isopropyl alcohol is basically a paint thinner, so if you use it before any soap and water, you run the risk of stripping the varnish off the object you’re cleaning.) This will clear all traces of resin from your immediate printing surroundings.

- Use resin to the last drop: While it’s tempting to rush out and buy new resin for all your projects, this can be quite wasteful. To get the most out of your resin, use a polypropylene or stainless steel mesh to pour whatever’s remaining from the printing vat back into the bottle. Just be very careful to avoid cross-contamination with other colors or types of resins!

- Treat it like the hazardous waste it is: The chemicals in resin are considered hazardous waste because of their toxic properties, so get familiar with the way your community handles the disposal of hazardous materials. Don’t forget that both the paper towel you wiped up resin with and the isopropyl alcohol that has resin in or on it need to be handled as hazardous waste, as well.

- Use environmentally-friendly resins: Several companies have created SLA 3D printing resins based on chemicals that are less harmful to the earth. Many of these biological resins are created from plants. Check out our next section for a list of places you can find these.

Environmentally-Friendly Resins

One way to keep your SLA 3D printing toxic waste to a minimum is by using bio-based resins. They’re formulated to offer the same features as regular resin without the dangerous side effects to you or the environment.

- Anycubic plant-based UV resin: Anycubic is an established printer and resin maker. In the case of this material, they’ve used their resources to research and develop an SLA resin made from plants. This biological base helps the liquid resin break down faster and safer, keeping human irritants to a minimum.

- 3Dresyns for SLA: If you’re not sure where to start with environmentally-friendly SLA 3D printing resins, 3Dresyns is a good place. Not only do they offer a wide selection of less toxic options, but their website also gives you the lowdown on what each resin is made out of and what it’s best at building.

- eSun bio-based PLA crossover SLA resin: eSun harnesses the biodegradability of PLA filament to create an SLA 3D printing resin. If you’re familiar with the properties of PLA, eSun’s liquid version is 100% compatible with SLA printers and brings its best attributes to your photochemical process.

Many resins are toxic to individual users and the environment when used without precautions, but with this guide, you should be well on your way to responsibly handling this unique material.