Prusa’s at it again, this time disrupting the 3D printing industry with Prusament filament. Keep reading to find out all you need to know!

How It All Began

We’ve all heard of Prusa Research. The company started by Josef Prusa creates some of the best desktop 3D printers in the world. Since its beginnings, the Prusa brand has been all about making in-house, high-quality products that deliver phenomenal printing results.

To deliver such a promise to the customer, a manufacturer needs to control all the variables of a 3D printing experience. These include the 3D printer itself, the software used for slicing the models, as well as the material used for the printing process.

As the years went by, Prusa developed incredible 3D printers like the recent i3 MK3S and offered its customers a slicer software suited for the printer. The only variable left for Prusa to control was the material, better known as filament.

All of that meant only one thing: Prusa needed to manufacture its own filament! Thus, Prusa Polymers was born, a division inside Prusa Research dedicated to making high-quality filament marketed as Prusament.

Anything but Ordinary

Before Prusa started manufacturing Prusament, the company was already offering filament through its online shop. And it still does. You can choose between PLA, ABS, PET, flexible, and special filaments from a few different brands. Naturally, all of these filaments are outsourced, meaning they’re produced by other manufacturers. For example, one of the non-Prusament PLAs offered by Prusa is manufactured by Plasty Mladeč, a Czech plastic manufacturing company.

Even now, with Prusament available, Prusa still sells these filaments. Why, you ask? Well, naturally they generate some extra revenue for Prusa. On the other hand, this system also offers easy access to customers looking for a variety of printing products. One element of this easy access is the ability to compare…

Under the Microscope

What makes Prusament special among filament brands is the overall quality and attention to detail. Prusament is manufactured in-house by Prusa, on the company’s very own filament production lines. Having all of the production under the same roof means that an extra degree of attention can be devoted to quality control, and that’s exactly what Prusa is very proud of.

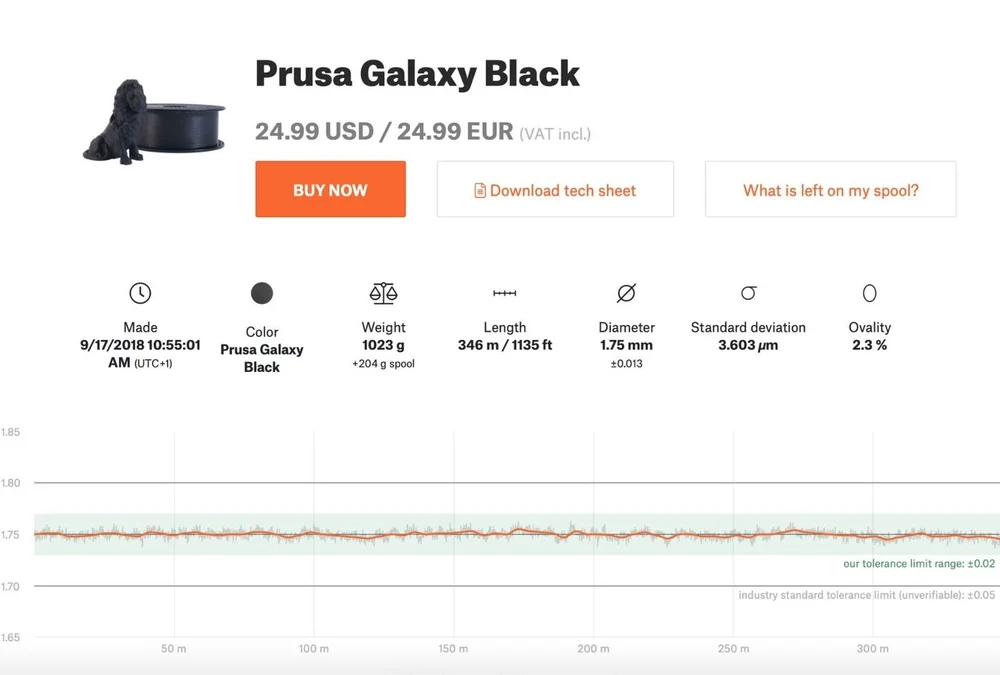

Each spool of Prusament comes with a QR code that leads the customer to a webpage where they can view the exact details of their spool. This includes details like the exact time when the spool was made, exact weight and length, and precisely-measured diameter deviation and ovality.

Even the spool that carries the material is impressive. The plastic honeycomb structure saves plastic but also brings down he weight. Furthermore, the central tube is made from cardboard to reduce overall plastic usage.

What’s the Catch?

The reality is that Prusament genuinely is top-class filament. But despite Josef Prusa saying that he wasn’t very satisfied with what was on the market, when you go and compare Prusament PLA with something like Fillamentum PLA, you realize that they both provide incredible results, so there isn’t much advantage for Prusament there. In fact, what Mr. Prusa really meant is that no manufacturer provides such tight diameter tolerances and quality control as Prusa does with Prusament. Fair point.

Overall, Prusament surely does raise the bar in the field, but is it that much better than other premium PLAs? Well, not really. What it’s really good at is providing smooth, beautiful prints, and that’s exactly what was needed for Prusa to deliver the complete 3D printing experience. The 3D printing community generally loves Prusament. On the forums, there are very few complaints and a great deal of positive feedback.

With the big picture in mind, let’s take a closer look at the different kinds of Prusament that are available.

PLA

The starting point of Prusament PLA is NatureWorks’s 4043D resin, which is a high-quality raw polymer base.

There are many colors available for this filament, including the special Mystic Green and Mystic Brown, which are sold at a higher price and marketed as “premium”. What’s unique to these two is the ability to change color depending on the nozzle temperature, and therefore provide special visual effects. For example, Mystic Green can be either gray-ish or green, while Mystic Brown changes from brown to purple.

All Prusament PLA filaments have a bit of glitter in them, which helps enhance the visual appearance and hide potential imperfections on the surface.

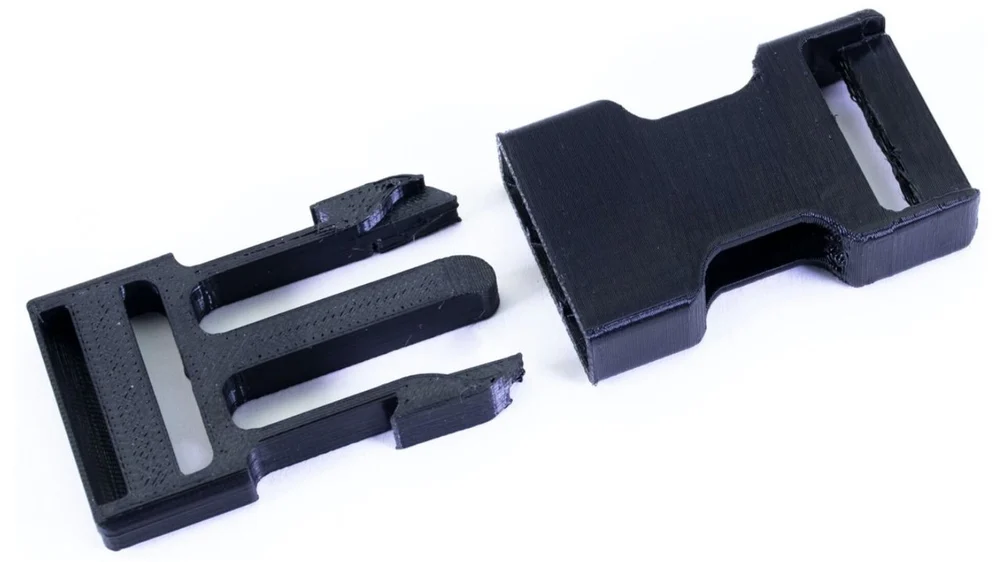

Prusa claims this filament prints easily, provides reasonable toughness, and has an extremely low warping potential. Our review of the Galaxy Black Prusament PLA and community feedback only confirm this.

No doubt, this is a high-end PLA that justifies its slightly higher price. If you’re looking for some extra fun, the additional $5 for the Premium colors are worth it.

- Colors: 15+ colors available

- Size: 1.75-mm, 1-kg spool

- Recommended settings: Hot end 200-220 °C, heated bed 40-60 °C

- Price: ~$25 (Premium ~$30)

PC Blend

Prusament PC Blend is a polycarbonate filament, meaning it’s rigid and well suited for making functional, mechanically-stressed parts. Whereas PLA is easy to print with, PC Blend requires both more experience and equipment.

Because it’s quite prone to warping when printing larger objects, it’s very important to keep the parts heated. To achieve that, you’ll need an enclosure for your 3D printer, which keeps the temperature in the build chamber and helps reduce warping potential. The enclosure will also help keep the sadly-noticeable printing odor from coming out.

A nice touch from Prusa is that they include a Kores glue stick with each spool of PC Blend Prusament. Once you do manage to make some parts with PC Blend, you’ll end up with tough, impact- and heat-resistant parts than can really serve a purpose under mechanical stress.

The most common problem with printing with PC Blend is bed adhesion, so make sure to use the included glue stick to prepare the build platform. Also, we’d recommend using a brim for larger prints.

With correct settings in place, you should get some nice, precise parts. What’s also great about PC Blend is that it can easily be sanded.

Yes, it’s a bit expensive, but considering it’s a high-end, high-performing filament, we can’t complain much.

- Colors: Jet Black, Urban Grey, Natural

- Size: 1.75-mm, 1-kg spool

- Recommended settings: Hot end 265-285 °C, heated bed 100-120 °C

- Price: Premium ~$50

ASA

Prusament ASA is like ABS filament, but better. The goal with ASA was to produce a filament that was just like ABS but with enhanced properties. When printing with ABS, it can get smelly, but with Prusament ASA, the smell is a bit less noticeable. Another difference with ABS is ASA’s UV stability (up to about 93 °C), which means it can be used for making outdoor parts that won’t be ruined quickly.

As great as that sounds, ASA still isn’t perfect. Although Prusa did put effort into making this filament easy to print with, warping is still an issue, especially with larger parts. As suggested by the Prusament website, an enclosure or the addition of a brim or skirt can help reduce the warping potential. Also, don’t forget to use a smooth PEI sheet, because once ASA sticks to the textured one, it can be a painful process to remove it.

On a more positive note, what’s really really good with ASA is the layer adhesion and the toughness of the printed models. If you look on popular 3D printing forums, you’ll see many users posting pictures of pure layer perfection achieved with ASA.

Pricing is the same as it is for Prusament Premium PLA, which seems logical and fair. With a bit of 3D printing experience and patience, you can create some amazingly smooth prints with ASA.

- Colors: Prusa Orange, Prusa Galaxy Black, Jet Black, Natural

- Size: 1.75-mm, 850-g spool

- Recommended settings: Hot end 255-265 °C, heated bed 105-115 °C

- Price: Premium ~$30

PETG

Prusament PETG is the material out of which some parts of the Prusa i3 MK3S are made! It can withstand more flexing than PLA, making it less brittle overall. Thanks to these properties, PETG is a good choice for making mechanical, functional parts.

Layer adhesion is strong and it can lead to difficulty when removing the prints from the print bed (using the textured sheet). However, the positive side of a strong layer adhesion is that there’s minimal chance of warping, and you can produce watertight prints.

The suggested temperatures work well, but Prusament PETG perhaps tends to prefer the upper values. Potential problems when printing include stringing, which can usually be solved by bumping up the retraction numbers.

Once you have proper settings in place, you’ll most likely be able to print it nicely. Judging by the forums, a small word of advice from the community is to speed up the cooling fan if you have stringing issues, but also to store the spools in a container with some silica gel because, once it absorbs even a little moisture, you’re looking at bad printing results.

If you’re looking for something that’s more capable than PLA, but still not hard to print with, this filament might be the perfect choice for you.

- Colors: Prusa Orange, Prusa Galaxy Black, Jet Black, Signal White, Urban Grey, Clear, Neon Green Transparent, Yellow Gold, Ultramarine Blue Transparent, Carmine Red Transparent

- Size: 1.75-mm, 1-kg spool

- Recommended settings: Hot end 240-260 °C, heated bed 70-90 °C

- Price: ~$30