Stereolithography (SLA), Digital Light Processing (DLP), and LCD are three very similar resin 3D printing technologies. They all use photopolymer resins in a resin tank, and cure the resin to form solid 3D printer models. But there are subtle differences to consider when choosing whether to buy a DLP vs SLA 3D printer, or when considering a 3D printing service.

This article considers the differences between SLA, LCD and DLP.

Conclusion First

There are many differences between the three main resin-based 3D printing techniques. The table below shows the generic differences.

| SLA | DLP | LCD | |

| Build Area | ★★★ | ★ | ★★ |

| Price | ★★★ | ★★★ | ★ |

| Speed | ★★ | ★★★ | ★ |

| Quality | ★★★ | ★★★ | ★★ |

One of the main drawbacks of Laser SLA techniques is its price for the machines and consumables. This also applies to DLP 3D printers.

DLP printers have another technical disadvantage to keep in mind, the (affordable) DMD chips are usually 1920*1080 pixels, which limits the quality of printing when upscaling the build area.

LCD-based printing is a lot cheaper compared to the other techniques. These machines are more affordable and also consumables like FEP foil for your resin tray are cheaper.

What most users don’t realize is that the LCD display also counts as a consumable, which should be replaced from time to time. The build area is dependant on each machine and technically it is easier to create a bigger build area, by placing a bigger LCD in the machine.

How they work

SLA 3D Printing

SLA uses a laser beam to selectively solidify parts of the resin, stored in a resin tank or resin vat. The laser beam is shone at the bottom of the tank, and is directed by mirrors called galvanometers to the precise area to be cured.

This continues until the layer is completely cured, before the build platform rises up by one layer, and the process repeats again and again until the part is finished.

DLP 3D printing

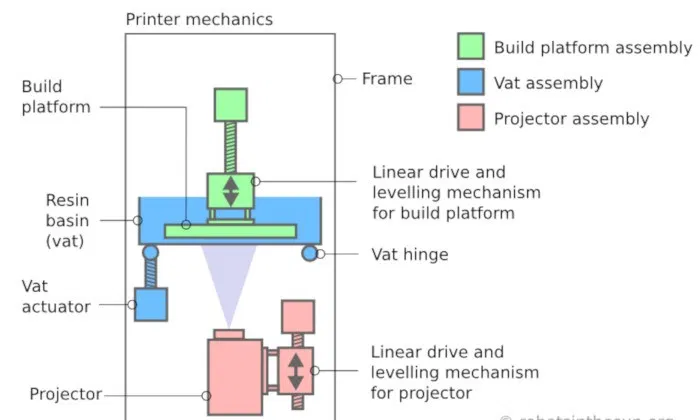

Digital Light Processing was invented a couple of years later in 1987 by Larry Hornbeck of Texas Instruments — though not for the purpose of 3D printing, but for movie projection, which the technology has wide use in.

DLP 3D printing uses a projector, rather than a UV light laser as with SLA. The projector flashes light onto the entire layer of resin at once, selectively solidifying the part using thousands of minuscule mirrors called DMDs (digital micromirror devices) that direct the projection of light.

These projectors use pixels, with layers consisting of voxels, as with regular 2D or 3D cameras.

LCD 3D printing

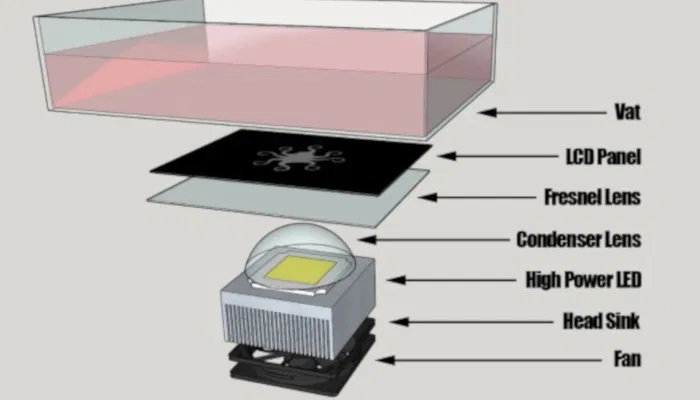

More recently, low cost LCD 3D printers have become popular, offering better quality than FDM 3D printers can for the same price. These resin 3D printers use LCD panels using LED lights to cure resin in a similar way to DLP 3D printers.

As with DLP, LCD 3D printing involves flashing entire layers at once to cure resin housed in the resin tank, but LCD printers don’t use mirrors. Instead, powerful LCD panels shine light via LEDs at the model, which the LCD panel blocks off in the areas that are not to be solidified.

The LCD screen only lets the light pass through areas that are to be cured into the finished part, simplifying the process and removing the need for any mirrors or galvanometers.

Key differences between SLA, DLP and LCD 3D printing

Though SLA, DLP and LCD are largely similar — they both cure resins and operate layer by layer — there are some key differences between them.

Resin Solidification

The biggest difference between SLA and DLP is the difference in method used to cure the resin.

DLP uses a projector, LCD 3D printing uses an LCD screen, and SLA uses a UV laser that traces the dimensions to be printed. DLP and LCD are faster than SLA as they can create entire layers at once, whereas SLA requires manually tracing the dimensions of each layer with the laser.

Another lesser difference but worth noting is that DLP 3D printers usually have shallower resin tanks — the tanks which resin material is stored in during printing. If you’re big on saving money this is an advantage, as this reduces the waste of expensive unused resins.

Print Speed

Due to SLA involving a laser passing over each area of the part to be solidified, while DLP and LCD can cure whole layers instantly, DLP and LCD are generally faster than SLA printers.

As for which is faster between DLP and LCD, again this depends on the 3D printer you purchase. More expensive resin 3D printers will likely print faster and at better quality, and a $2,500 DLP 3D printer will almost certainly print faster than a $300 LCD 3D printer.

Print Quality Comparison

Resin 3D printing is known for being one of the most accurate and precise 3D printing technologies, and even low cost LCD printers are able to create complex geometries that technologies like Fused Deposition Modeling just cannot match.

Honestly, the print qality of an LCD 3D printer compared to a DLP or SLA 3D printer depends on the 3D printer used. An expensive SLA 3D printer will be far better than a cheap DLP 3D printer, with higher quality components used and better resolutions and precision.

The technologies themselves are similar in their ability to create accurate models, it is the execution that affects quality.

Resin Comparison

Some resins may work with both DLP and SLA printers, or with DLP and LCD printers, so there is some overlap. But not always, as though some 3D printer companies allow their machines to be used with any third-party resins, some restrict them to only use their branded resins.

The best resins for you ultimately depend on what you’re looking to achieve with SLA, DLP or LCD 3D printing. Basic resins exist for fun, hobbyist 3D printer projects, as well as specialized castable, dental, engineering, or 3D printed jewelry resins.

More industrial and professional quality resins will cost more, and can cost upwards of $100/liter. The most basic resins can cost far less, at around $40, but will not offer the same level of quality, even on high-quality resin printers.

3D Printing Services

Still wondering which technology is the best one for your creation? FacFox’s engineers are always online to give you help. Please contact us at info@facfox.com. We have industrial SLA, LCD as well as DLP 3D printers. And we’ve accumulated rich experience in printing resin prototypes, art pieces, teeth models, etc.