PETG is a great material to 3D print with, even if it is a little stringy. Read on for three easy ways to fix PETG stringing!

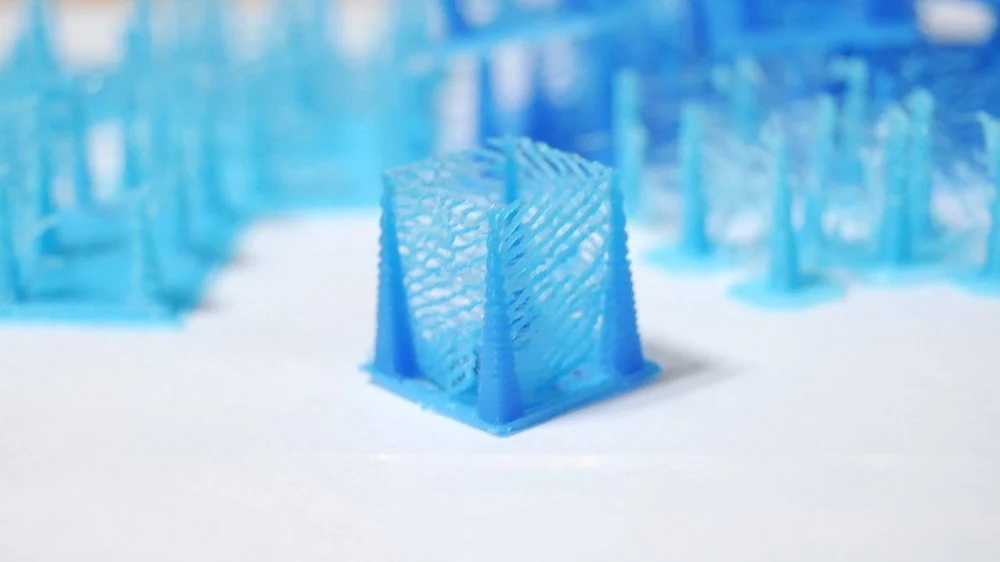

Stringing is a very common problem in 3D printing. Basically, stringing or oozing occurs when melting filament oozes while the nozzle is traveling between two points. This problem gives prints annoying “hairs” that can be difficult to remove.

PETG is especially notorious for stringing because it requires a relatively high temperature to ensure good flow. This increased temperature can encourage strings, allowing the filament to freely flow while traveling between two points.

This article will explore three tips to print PETG without those pesky strings.

Tip #1: Increase Retraction and Decrease Minimum Travel

If you’re struggling with stringing, you should first tweak your retraction settings. When retracting, the extruder motor pulls a set distance of filament from the nozzle. This operation should prevent unwanted oozing either on or between printed parts.

In your slicer’s settings, start with a retraction speed of around 25 mm/s (for both Bowden and direct drive extruders) and a retraction distance of 6 or 7 mm for Bowden extruders and 3 or 4 mm for direct drive extruders.

If stringing persists, you can tweak these settings in tiny increments to dial in the perfect retraction settings for your printer. First try increasing the retraction speed by 5-mm/s increments, but be careful not to set the speed too high otherwise it may jam the nozzle. You can also try increasing the retraction distance by 1-mm increments.

Related to retraction, you can also try reducing the minimum travel. This setting decides the minimum distance the printhead needs to travel before fully retracting the filament. Reducing it will make sure that even small distances are rid of strings.

Tip #2: Decrease Nozzle Temperature

If fixing your settings for retraction doesn’t work, it’s time to chill out – literally. In other words, decrease your printer’s nozzle temperature. Obviously, if your filament is getting too hot, it will freely ooze regardless of retraction or travel settings.

To tweak your printer’s temperature, try printing a temperature calibration block or a “temperature tower“. Most come with instructions to find the perfect nozzle temp in a single test! Be careful as you work to find the perfect temperature: You don’t want to eliminate stringing at the cost of a smooth surface finish.

Tip #3: Increase Travel Speed

Another quick fix for PETG stringing is to increase travel speed. The quicker the nozzle moves between two points, the less time melting filament will have to ooze.

Try increasing your printer’s travel speed in 10-mm/s increments until you find the perfect speed. Some makers even use travel speeds of up to 200 mm/s.

3D Printing Troubleshooting Common 3D Printing Problems

Source: https://all3dp.com/2/petg-stringing-3-easy-ways-to-prevent-it/