SLA is one of the most mature, stable, widely used 3D printing technologies in the market. We always encounter some problems that are difficult for a green hand to understand. Today we are sharing about one common failure in operating SLA machine: why it’s so difficult to print a cup-like object of which the supporting design is reasonable and the structure is not complicated?

Before we come to the cup mouth effect, you need to know a concept: surface tension. Generally speaking, surface tension refers to the force of attraction between various parts of the liquid surface. Surface tension is the tendency of fluid surfaces to shrink into the minimum surface area possible.

It allows insects (e.g. water striders), usually denser than water, to float and slide on a water surface. When we pour water into a cup, we can always pour more water without overflowing, even if it’s already full. As for SLA printing, because the photosensitive resin is also a kind of viscous liquid, it will also be affected by the surface tension.

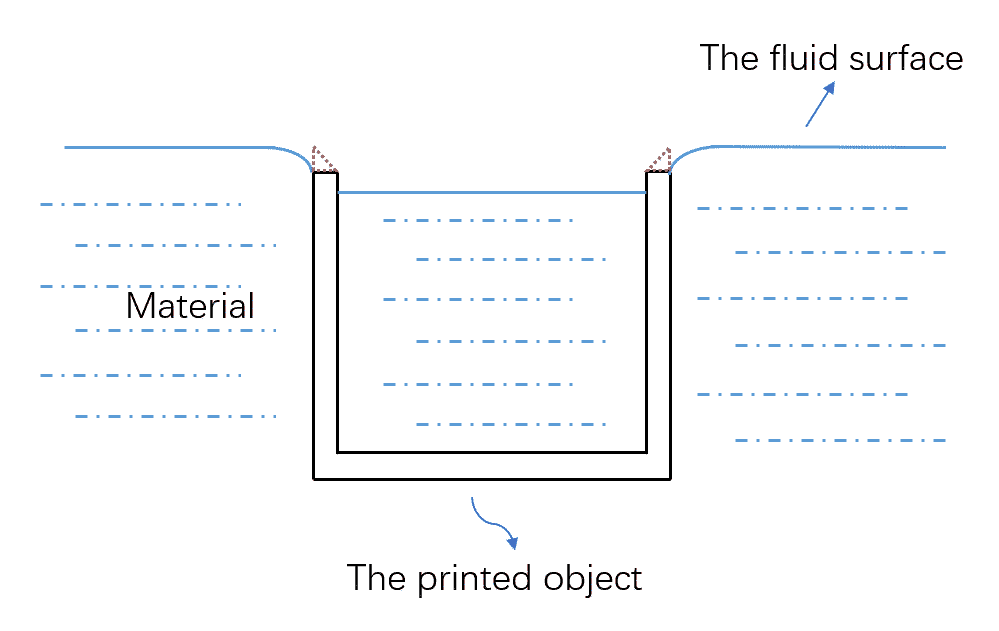

As shown in the figure, the full line depicts the part we are making, and the internal material of the part is not connected with the external material. When we finish one layer, the tray will drop a unit height. The external material of the part cannot flow into the part due to the surface tension, so the internal material is too thin to form one layer, and the liquid level is lower than the external one. We call this kind of failure the trapped volume or the cup mouth effect.

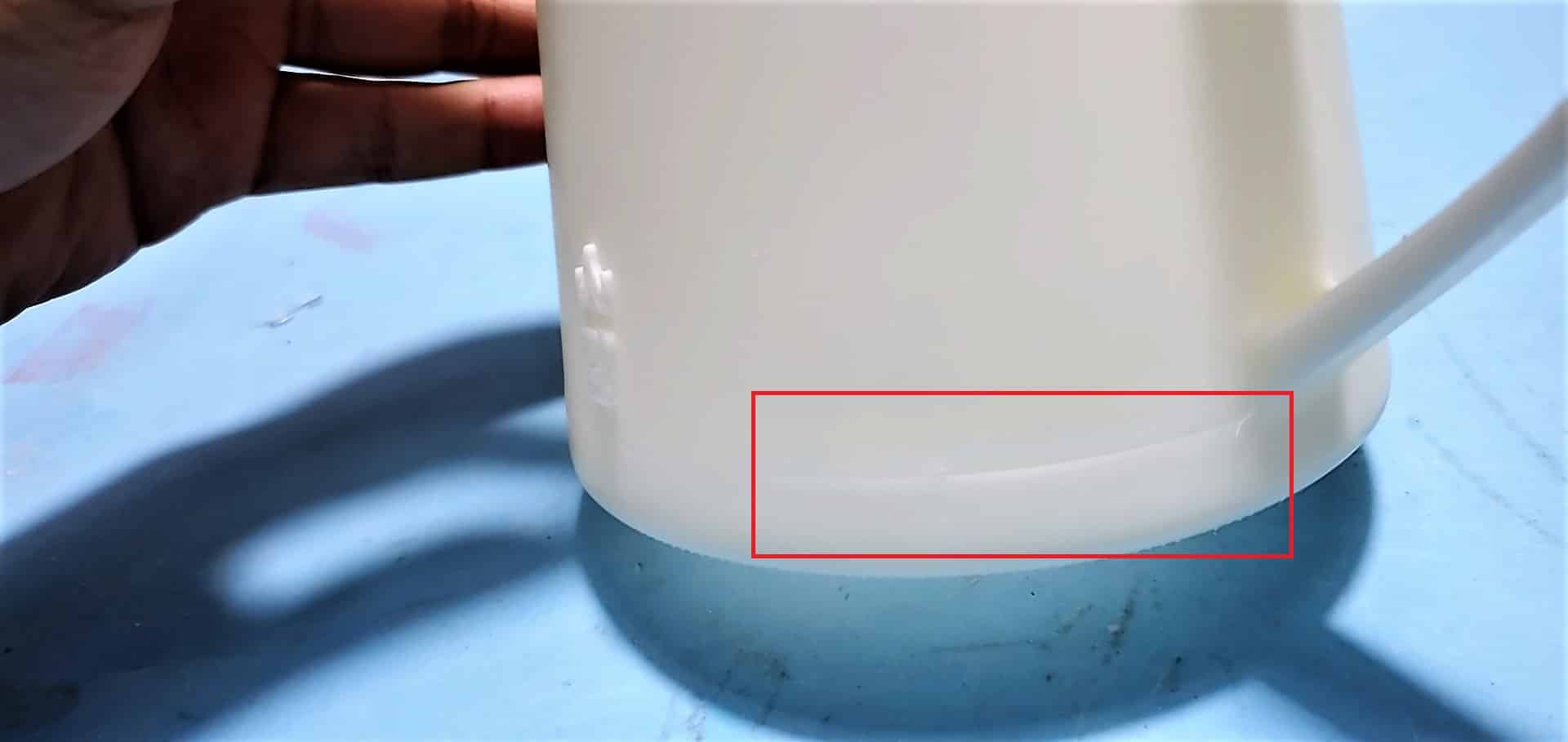

The cup mouth effect is often accompanied by too little inner materials and the wrong height of the final part, which both result in thin wall thickness. If the wall is too thin, there is always a gap or “stage” emerging in the cup mouth.

We can detect if there is enough material around the cup mouth. Sometimes the scraper has the function of scraping and coating materials. If the volume of the object is too large, and the scraper cannot push enough material into the cup, we can punch holes at the bottom to make the materials flow, or change the placement angle to decrease the size of cup mouth.