Electric circuit connectors are essential components for transmitting electrical signals and power between different devices and systems. They require high precision, reliability, and durability to ensure the performance and safety of the circuits. However, conventional fabrication methods, such as machining, molding, and stamping, have limitations in producing complex and customized connectors with high efficiency and low cost.

Micro 3D printing is a technology that can overcome these challenges and create novel and optimized connectors at the micro and nano scale. Micro 3D printing uses a light source, such as a laser or a projector, to selectively cure a liquid resin into solid structures with high resolution and accuracy. Micro 3D printing can offer many advantages in the fabrication of precision connectors, such as:

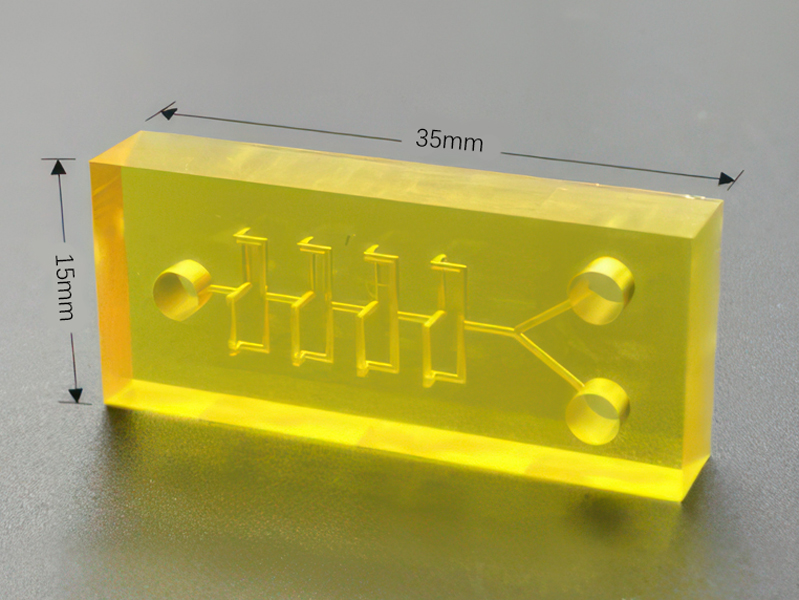

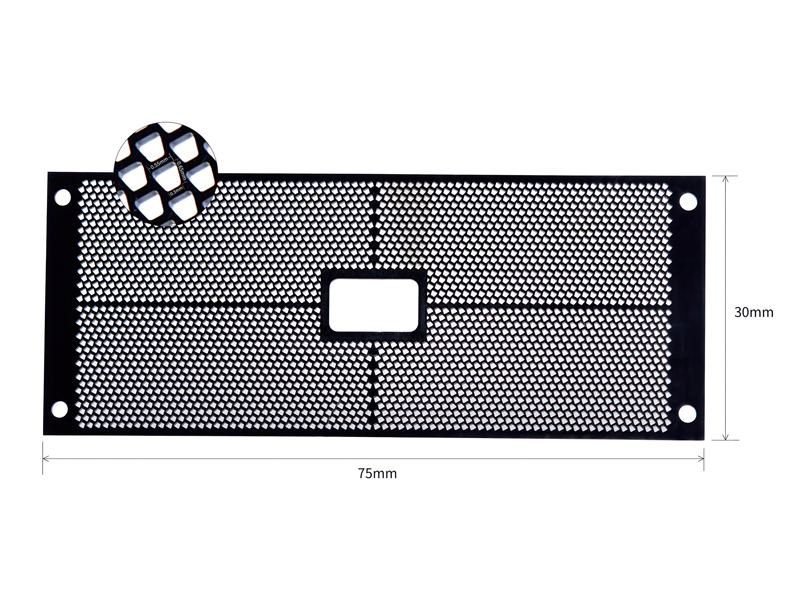

- Design flexibility: Micro 3D printing can create connectors with complex geometries, such as networked, interlocking, and internal features, that are difficult or impossible to achieve with traditional methods. These features can enhance the functionality and performance of the connectors, such as interface connection, internal communication, and material properties.

- Cost efficiency: Micro 3D printing can reduce the material waste, tooling cost, and assembly time of the connectors, as it can create them directly from a digital model without the need for molds, dies, or pins. Micro 3D printing can also enable mass customization, as it can produce different connectors with the same setup and process.

- Quality consistency: Micro 3D printing can ensure the quality and repeatability of the connectors, as it can control the curing parameters, such as light intensity, exposure time, and layer thickness, with high precision and accuracy. Micro 3D printing can also minimize the defects and errors of the connectors, such as cracks, warping, and misalignment, by optimizing the design and process parameters.

FacFox is a leading company that provides micro 3D printing services for electric circuit connectors. FacFox has developed a proprietary projection micro-stereolithography (PμSL) technology that can achieve ultra-high precision of 2μm, and also has high tolerance control capability. FacFox’s technology advantage is that it can process cross-scale parts, ranging from microns to centimeters, with lower difficulty than printing at a single scale.

FacFox has a range of printers to meet the different needs and specifications of the customers, such as:

FacFox’s printed connectors can provide efficient and reliable solutions for large-capacity data transmission and high-speed high-density connection fields, such as telecommunications, aerospace, and automotive. FacFox is committed to continuous innovation and excellence, and aims to lead the development trend of electronic miniaturization, precision, and integration.

Micro 3D printing is a breakthrough technology that can revolutionize the electric circuit connector industry. It can create complex and precise connectors with high efficiency and low cost, and improve the performance and reliability of the circuits. Micro 3D printing is widely used in the fields of precision parts, medical, consumer electronics, and scientific research, and has great potential for future applications and developments.

If you are interested in learning more about micro 3D printing and its application in electric circuit connectors, or if you want to get a quote for your project, please feel free to contact us at info@facfox.com. We will be happy to answer your questions and provide you with the best service.