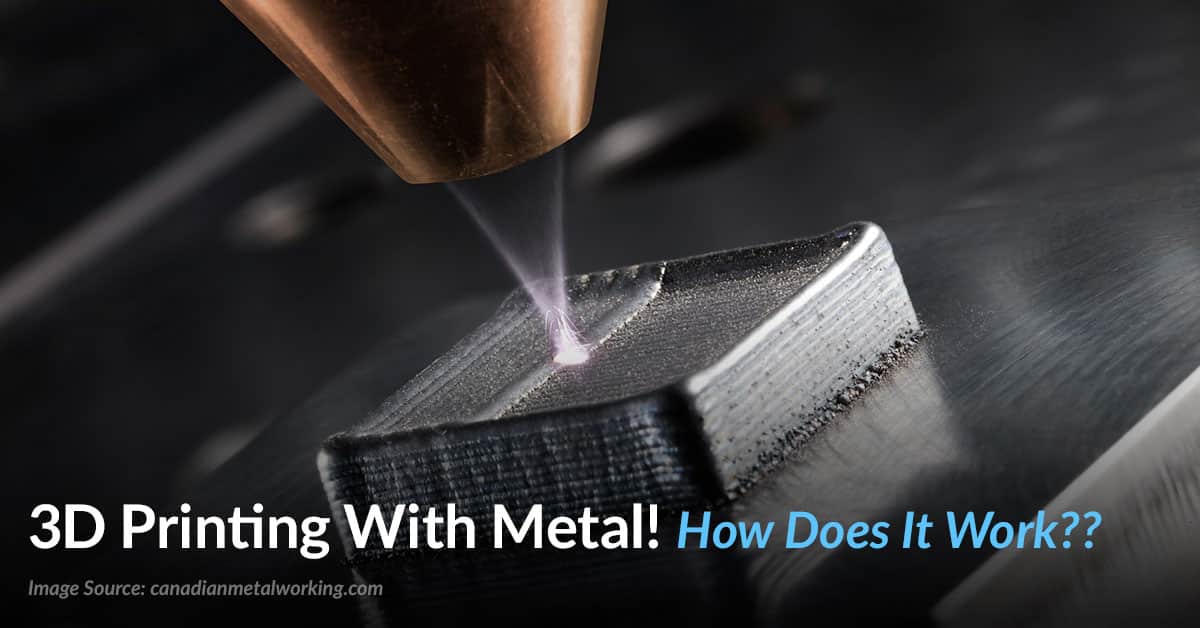

Metal powders are widely used in 3D printing. However, it’s not a common material for desktop 3D printers’ users. Many people have asked us what kinds of metal powders can be 3D printed, which 3D printing technologies are capable to use metal powders. Here Facfox is telling what we know.

3D Printing Technologies That Can Directly Use Metal Powders

3D printing technologies that can directly use metal powders include SLS (Selective Laser Sintering), SLM (Selective Laser Melting), EBM (Electron Beam Melting), LENS (Laser Engineered Net Shaping), etc.

Compared with polymer, photosensitive resin, and other inorganic non-metallic materials, 3D printers that can use metal powders have higher prices and operating costs, and the process is more difficult, which greatly limits the use and development of metal materials in the 3D printing field.

Types and Requirements for Metal Powers Used in 3D Printing

The metal powder used for 3D printing generally requires high purity, good sphericity, narrow particle size distribution, and low oxygen content. The metal powder materials currently used in 3D printing mainly include titanium alloys, cobalt-chromium alloys, stainless steel, iron powder, aluminum powder, and aluminum alloys. In addition, there are precious metal materials such as gold and silver used for 3D printing jewelry.

How to Produce Metal Powders?

At present, the powder preparation method can be mainly divided into the reduction method, electrolytic method, carbonyl decomposition method, grinding method, atomization method and the like. Among them, it is more common to use powder produced by reduction, electrolytic and atomization methods in the powder metallurgy industry.

However, the electrolytic method and reduction method are limited to the production of elemental metal powder, not applicable to alloy powders. The atomization method overcomes the shortcoming.

At the same time, the modern atomization process can control the shape of the powder. The continuously developing atomization cavity structure has greatly improved the atomization efficiency, which makes the atomization method gradually develop into the main powder production method.

Atomization Method

The atomization method refers to a method of pulverizing a molten metal into particles having a size of less than about 150 μm by a mechanical method.

According to how to crush the molten metal, the atomization method can be divided into two-stream atomization method, centrifugal atomization, ultrasonic atomization, vacuum atomization, and the like.

These atomization methods have their own characteristics, and they have been successfully applied to industrial production. Among them, the water vapor atomization method has the advantages of simple production equipment and technology, low energy consumption, large-volume production, etc., and has become the main industrialized production method of metal powder.