Do you have a box of old and broken toys that you have been cherished in your childhood? Or have you ever worried that the throwaway habit may be brought into the adulthood of your children? Children are born with strong destructive power, but it reflects how they explore the world. A toy usually has to retire in just a few weeks, which also aggravates environmental pollution.

However, with the help of 3D printing, you can repair your toy and no more need to throw it away as long as it broke down. During the fix process of the old toys, if your children are older than 10 years old, the 3D printers can also become their new toys. Some smart parents have already taken this idea into practice.

To recreate the missing wheel for a mini car with a 3D scanner.

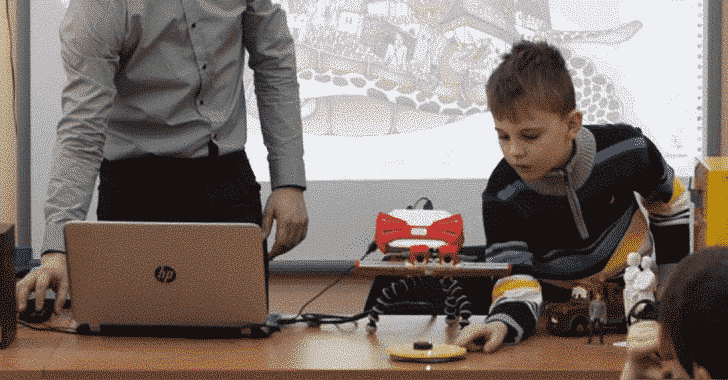

Many toys are discarded because of cracking, but mini remote cars are always thrown away after just losing one wheel. The team of RangeVision 3D showed to the school children how they can recreate the missing wheel with new 3D scanning and 3D printing technology.

No engineer’s qualification or access to huge machine facilities is needed during the repair. The RangeVision 3D printer can help you simply scan the existing wheels and provide the digital file of exceptional quality, based on the principle of structured light. The scanners are capable of scanning objects from jewelry to auto parts, or other objects in different shapes or sizes, by scanning the scanners’ field of view.

So the repairing process becomes quite easy. First, took an unbroken wheel from the mini car, scan it with a RangeVision Smart scanner. Then, processing the scan file in the software and output to a 3D printer. A new wheel is generated successfully. Let’s try to assemble it onto the car — it works!

To download a spare part file from the Toy Rescue platform.

The European 3D printing company Dagoma hopes to “give everyone the opportunity to repair an item” that may otherwise hit the landfill. They launched the project Toy Rescue, which dedicates to provide free 3D printable toy models.

The project aims at creating spare parts for the most popular toys in the world. A team of Dagoma scans hundreds of toys and modeled easily-broken parts in 3D, creating digital files that users can download from Toy-Resue.com to print the parts they need to fix old toys instead of buying new ones. Users can also request files for parts that can’t be found.

There are legs for Rex, the dinosaur from “Toy Story,” ears for Mr. Potatohead, arms for Barbie and feet for Bratz, stormtrooper helmets and parts for the Millennium Falcon and Game Boy. The lifetime of those toys is significantly extended.

Dagoma also suggests printing the spare parts using plant-based filaments as they are eco-friendly. They also try to recycle the unrepairable plastic toys into filaments and reuse them into fixing other toys.

To repair a relatively complex toy with CAD design skills.

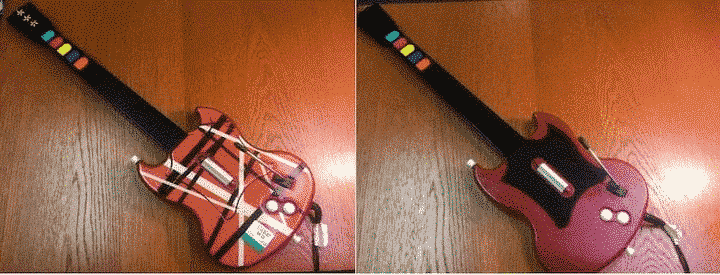

Robert Maldonado, the application engineer at DesignPoint, obtained the ancient Guitar Hero video game at a thrift store, but the guitar is already broken, the bar’s internal attachment had worn away and broken.

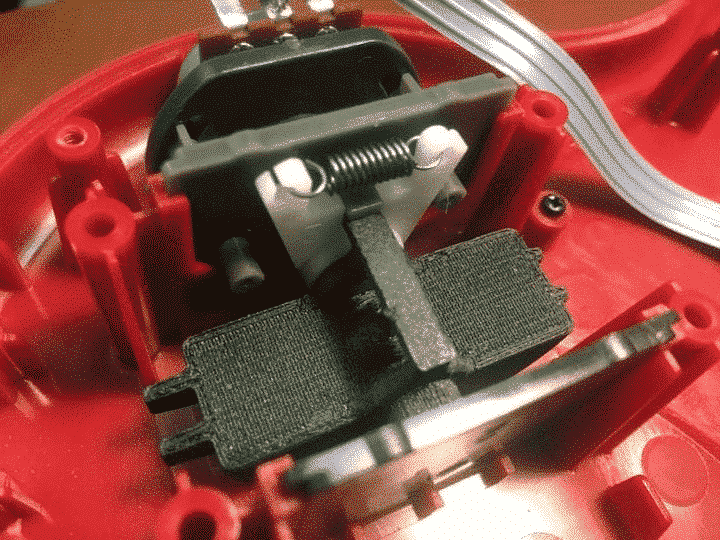

For common people, the broken attachment sentence the death of the guitar, unless they can purchase another unit or cannibalize another guitar. However, as a design engineer with CAD design skills, Robert took apart the guitar and measured the original’s dimensions with calipers and forming a similar geometry in SOLIDWORKS.

He redesigned the spare part and incorporated several minor fixes into the new design, making the new part much stronger. He recorded: “I changed the cantilever design to a doubly-supported overhanging design, which should give it better resistance to the bending moment that it experiences during use. NOTE: this would make it very difficult to mold without the use of side cores, but since we are 3D printing, we have that design flexibility!”

The internal transformation and the external cleaning work was completely done in one day, driven by the nostalgia for his youthful experiences.