“We would not have been able to reach the same level of efficiency without implementing a workflow automation solution for our additive manufacturing facility. Thanks to AMFG, we now also have full workflow visibility.” – Jacob Turner, Head of Additive Production

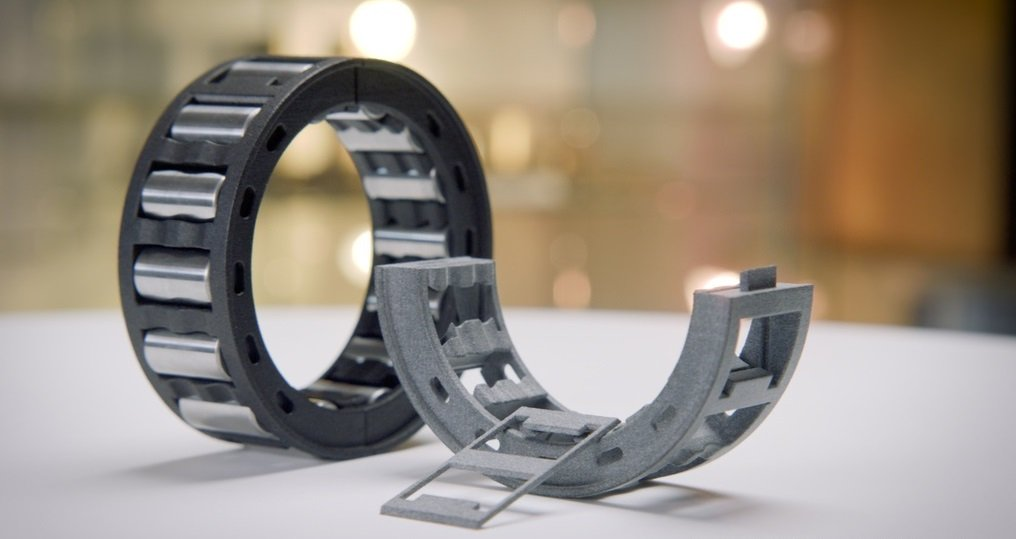

With over 40 years’ industry experience, Bowman International is one of the leading manufacturers of bearings and sintered components. As part of its move to further expand its ever-growing production capacity, the company recently launched its additive manufacturing division — Bowman Additive Production.

The division is dedicated to end-part production of bearings and components using additive manufacturing technology. But how has implementing AMFG’s automation software helped Bowman streamline its AM production processes?

The Challenge: Creating an Efficient AM Production Process

The bearings market is facing a rising demand for additive manufacturing. The technology offers a cost-efficient way to produce complex end-use parts, enabling the manufacture of products that would otherwise be impossible using traditional manufacturing methods.

Bowman, with its state-of-the-art SLS and HP 3D printing systems, uses additive manufacturing to produce bearing production parts and prototypes.

However, after launching its additive manufacturing division, the Bowman team realised early on that it would need an efficient way to manage its AM production facility, as well as handle the significant volume of parts it produces on a daily basis.

The team was therefore on the search for dedicated workflow management software that would be able to manage each stage of the production process.

This would include optimising digital CAD files for production, handling project requests as well as enabling efficient machine scheduling and automatically-generated KPI reports. Any software would also have to integrate with Bowman’s internal ERP system.

“We realised from the get-go how important automating our production processes would be to achieving an efficient production workflow,” said Jacob Turner, Head of Additive Production at Bowman International. “That was the impetus behind our search for workflow management software tailored to additive manufacturing production.”

The Solution: AM Automation Software

After trying a number of different software solutions, the Bowman team opted for AMFG’s AM automation software. “The benefit of AMFG is that it gives us a way to manage the entire additive manufacturing process from beginning to end,” said Jacob.

“Compared to the other solutions on the market, AMFG is the only one that provides an effective means of tracking our projects, scheduling production jobs and ensuring that all of our parts are tracked as they move along the production workflow. This added visibility is exactly what we need as we expand our additive manufacturing capacity.”

Following a period of consultation and training, Bowman was able to get started with AMFG. Bowman uses the software for each stage of its production cycle, starting with streamlining its project management process.

Instead of manually receiving new project requests via email, for example, the Bowman team can automatically receive requests through the platform. The software, driven by machine learning algorithms, is then able to conduct 3D printability analyses for each CAD file, including wall thickness checks.

“The part preparation feature allows us to optimise our CAD files before they are sent to production,” explains Jacob. “We’ve been able to save a significant amount of time by automating the verification process, instead of having to check each file manually.”

Another benefit of AMFG’s software is that Bowman can automate much of its production. For example, the company uses the software’s production management feature to allocate parts to a build and check the status of each build.

The team is able to see to which machine each build has been assigned thanks to AMFG’s Gantt View page. Jobs sheets and production reports are also automatically generated by the software. Bowman’s production facility is therefore able to run smoothly and efficiently.

The Result: Greater Efficiency

Bowman has already begun to see the benefits of implementing AMFG’s system within its additive manufacturing division.

“We’ve been able to significantly streamline the production process from the very beginning, and this has helped our productivity and throughput,” said Jacob. “We would not have been able to reach the same level of efficiency without implementing a workflow automation solution. Now we have full workflow visibility and high productivity.”

“We’re also very happy with the level of support provided by the AMFG team, and we’re excited to see what the future holds for Bowman Additive Production.”

The company plans on implementing more of AMFG’s solutions, including the software’s unique digital part catalogue and supplier integration tools.

About AMFG

AMFG provides automation software for additive manufacturing. With a complete workflow management solution, we help companies achieve highly efficient and automated AM workflows. Visit www.amfg.ai to find out more.