Toolings and fixtures are important components on metal cutting machines, especially in the field of non-standard toolings and fixtures, which are characterized by a small number and complex geometries. The application of 3D printing in the field of toolings and fixtures is developing further and further.

3D printed toolings

Additive manufacturing technology enables us to build toolings with complex internal geometries. It is through the 3D printing technology that Mapa created the complex spiral cooling channels of QTD series tools, thereby improving the heat transfer capacity when the coolant flows to the top of the drill. Mapa’s 3D printed drills have a longer service life and run faster than the previous ones.

The diameter of this internally-cooled tooling cannot be too small. Before adopting 3D printing, the smallest diameter of Mapa’s tooling can only be 13mm. With the help of LaserCUSING 3D printing technology, the laser can be manufactured in the range of 8mm to 32.75mm.

3D printed hydraulic fixtures

The large clamping force of the hydraulic tool holder helps improve the accuracy and reliability of the machining process, but it is easy to have the defect of poor heat resistance. As more and more processes in the metal cutting process involve high-speed machining, bad heat resistance of hydraulic fixtures has become a major issue that needs to be addressed.

Mapa has been studying this problem since 2009, and they have found a suitable solution with the help of Concept Laser’s LaserCUSING 3D printing technology. By adopting a special steel-based metal powder and re-involving the design of the hydraulic tool holder, Mapa’s new design significantly improves the ability of heat conductivity.

3D printed fixtures

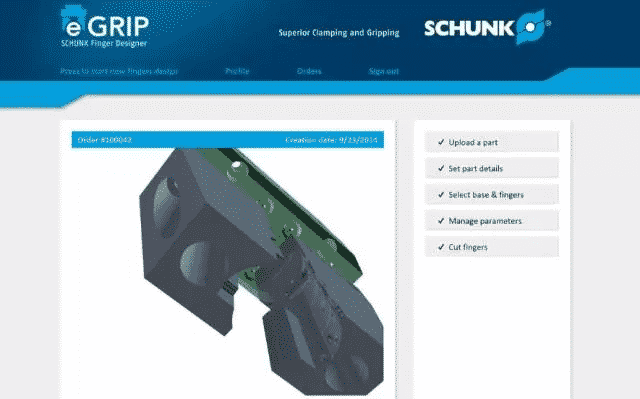

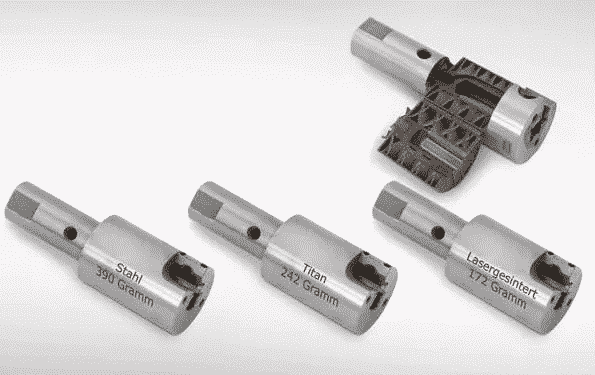

Materialise cooperated with SCHUNK to develop fixtures for clamping workpieces on machine tools. They jointly launched the SCHUNK egrip online free platform. Customers can create clamp programs in a few simple steps based on the browser.

The users can upload the STEP or STL file of the product to be processed and the related data, such as the weight of the item, the base of the fixture, the installation direction, position, and some clamps. The application will automatically generate an optimized design and provide the price and delivery information, order clamps instantly online. These clamps can be made in just a few days using an SLS polyamide process through the Streamics 3D printing control and automation software.