Many people are intrigued by so-called “exotic” wood-infused PLA blends. Let’s try Hatchbox’s version, which comes at their typical low price point!

What’s Special?

Hatchbox is a filament brand based in the USA. It offers a large variety of filaments, ranging from everyday PLA and ABS to more exotic blends like this Wood filament.

Boasting high-quality materials, Hatchbox advertises a plus or minus 0.03-mm precision in all of its filaments (that’s right – all of them). Hatchbox materials are currently supplied by North Bridge New Material Technology, a Chinese manufacturer that also offers its own Kexcelled brand.

Hatchbox Wood PLA is made with a blend of “plant-based materials, polymers, and wood particles” making it more environmentally friendly. Additionally, the models produced with this filament will have a wood-like finish, allowing you to sand and stain it like real wood.

A 1-kg spool of 1.75-mm Hatchbox Wood PLA costs $29.99. It is available in both 1.75 mm and 3 mm.

The Verdict

Throughout our tests with this filament, the results were good, but we encountered a large issue with stringing in prints. This isn’t a problem if you already plan to sand and finish your models, but otherwise, they will require more work than most other PLAs.

The filament came nicely packaged in a recyclable cardboard box, vacuum sealed in a plastic bag with a desiccant pouch. The bag was resealable, so you don’t need to worry about where to safely store your filament.

Test #1: 3DBenchy

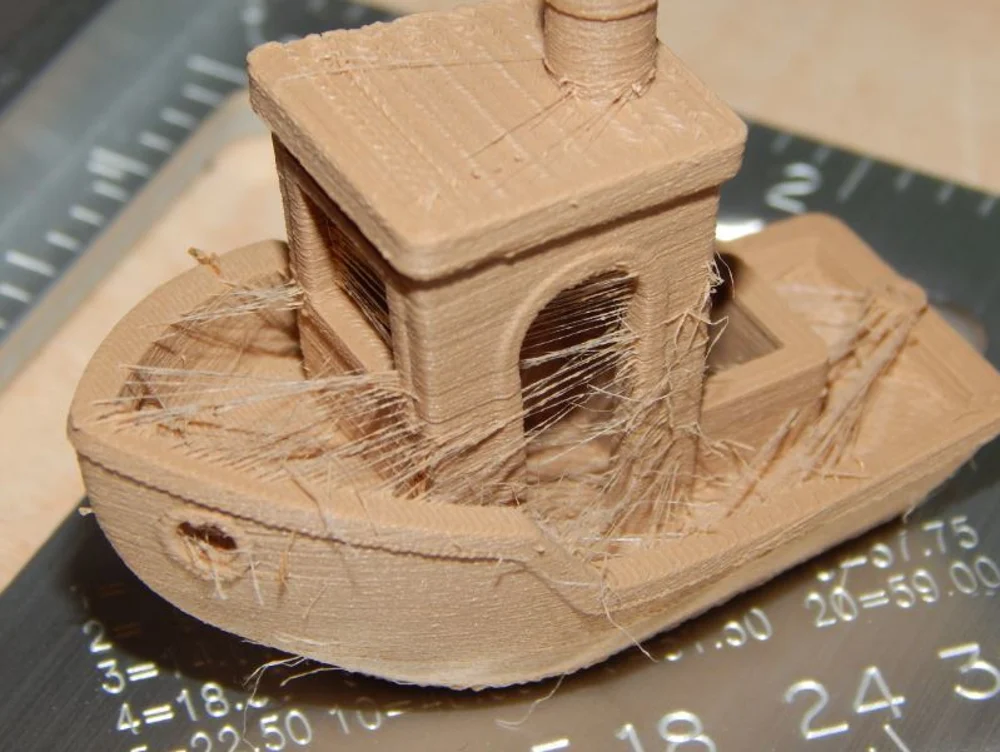

Our first test, as usual, is the ubiquitous 3DBenchy. Our print finished fine, but immediately we could tell that stringing was going to be an issue with this filament.

A close-up look reveals that the layers are fairly even, but have a rough wood-like edge. All of the details turned out crisp, aside from the obvious stringing.

Test #2: Barrel

Our second test was a screw-top Barrel by Nicholas Dimelow. Printed in a single go, the results were good. All the details turned out fairly well, and there was less stringing between the parts than we had expected.

Within the barrel, there was a fair bit of stringing, however. The screw cap was a very tight fit, and the models would require a bit of sanding to fit together as intended.

Additionally, we noted that the flat tops of the objects turned out quite rough, as the nozzle of the printer leaves ridges in the material during printing.

Test #3: Baby Groot

Our third test, inspired by the material, was a standing Baby Groot, by Dav Lov. As with the previous prints, it came out very stringy.

The supports were interesting to remove, as they don’t snap like regular PLA would — they sort of peel off of the print. Unfortunately, Groot lost a few fingers in the process, as the details were very small and the layers did not adhere well enough to each other, instead breaking off along with the supports. Hopefully, he’ll get over it and grow them back.

There were no other issues with this model, the details all came out nicely (aside from the fingers). Even with the strings, the surface finish was fairly uniform, again having a slightly grainy wood texture.

Final Thoughts

Overall, the filament was enjoyable to use. The stringing is only an issue if the models are not meant to be post-processed. Otherwise, it can be quite easily removed with a few passes on sandpaper.

This filament handles fine detail relatively well, considering its grainy texture, and definitely gives prints that wood-like finish. All in all, a recommendable experience.

Specs & Settings

A form of PLA, this filament will print well with most generic PLA profiles. However, with a few tweaks, the results will likely go from good to great.

We 3D printed using the “Colorfabb woodfill” and “0.15 mm Quality” settings in PrusaSlicer for best results, with the following changes:

- Nozzle temperature: 200 °C

- Bed temperature: 60 °C

The manufacturer’s specs and settings are as follows:

- Nozzle temperature: 175–220 °C

- Filament diameter: 1.75 or 3 mm (±0.03 mm)

How We Review

For those curious about how we arrived at our conclusion, we review filaments using the following guidelines:

Each and every spool is brand new and unopened.

Our first print is always a 3DBenchy. We use this to check for any inconsistencies in quality, color, and finish. After that, we print a few other models, the results of which we present to you. We slice the model using the latest version of PrusaSlicer. We do not post-process the prints in any manner; we simply remove them from the bed and cut off any support materials.

We start with the manufacturer’s recommended settings (where available). When the manufacturer offers a range of values, we go for the arithmetic mean. Therefore, if we are given a printing temperature range of 200–220 ºC, we would print at 210 ºC (unless noted otherwise).

For this review, we used an Original Prusa i3 MK3S in stock configuration. Statements regarding print quality are based on the printer’s ability and reputation to successfully print a wide variety of other filaments and models.

We would like to mention that every spool of filament can be slightly different, and filaments often vary greatly even within a small range. Simply fiddling with a single setting like retraction can have huge effects in print quality. This can make the difference between a disastrous fail and a wondrous success.

So, if you own a spool of this filament, we invite you to contribute in the comments below! Did you manage to get your prints to turn out? Did you have an interesting or strange experience? Let us know – we’d love to hear from you!

Feature image source: Emmett Grames / All3DP