What’s your envision about how we can make breakthroughs in the 3D printing industry in the future? Facfox is dedicated to expanding the building envelope as well as improving the precision, resolution, and accuracy.

Nowadays, the performance of printing an extreme size of objects is far from satisfactory. For those giant models, we need to split the STL files with some cutting tools and print the parts separately, then join all the pieces into one single model use an adhesive. Sometimes you may need to design pegs and holes in the model for smooth and easy assembling. Either method can not guarantee the reliability of the joints.

As for super tiny parts, the challenge lies in precision and accuracy. The default layer height of common 3D printers has restricted the minimum size of printed objects. No to say that small objects have tiny feature height. The minimum aperture is also big trouble, which affects the functionality of prints.

The specifications of the top sold desktop SLA 3D printers and general industrial 3D printers are summarized in the below table.

| Build Volume | Layer Thickness | |

| Desktop SLA Printer | 300*200*200mm | 0.02-0.2mm |

| Industrial SLA Printer | 1000*800*600mm | 0.05-0.2mm |

| FacFox Large-Format SLA Printer | 2400*800*800mm | 0.05-0.2mm |

| FacFox Micro-Precision SLA Printer | 10*3.84*2.16mm – 50*50*10mm | 5-20μm |

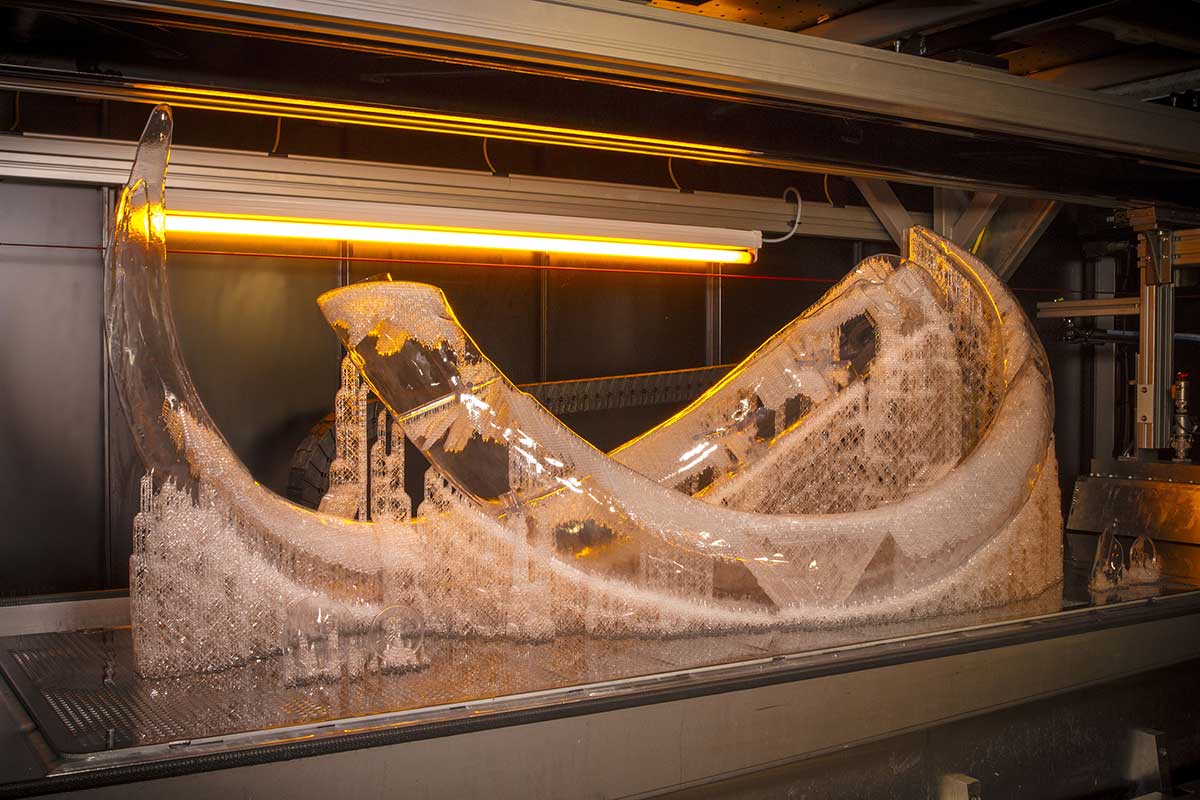

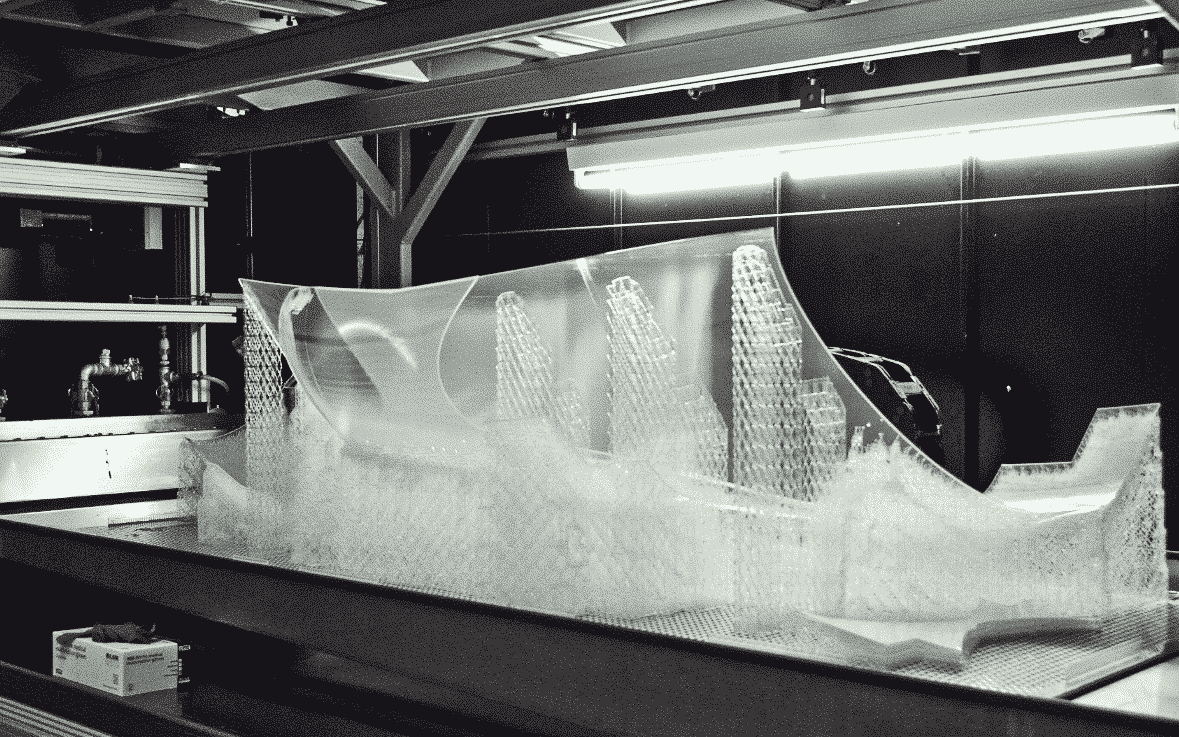

Facfox Large Format SLA 3D Printing

The large format is semi self-designed by our technicians. You can check our case library to review the Budda sculpture and front bumper we produced using this machine.

- Material: Resin

- Technology: SLA 3D printing

- Application: Oversized statues and models for display and exhibition; prototype verification of automotive.

The large-format SLA printer brings advantages that normal industrial SLA printers could not offer:

- You can print a giant object in one piece with no need to split the model. In this way, the difficulties of modeling have been avoided, which directly decreases the labor cost.

- No more assembling work. That means we can save time on gluing the parts together and other post-processing, also good for our customers. And the appearance of the printed part will be perfect without a seam.

- No worry about the strength of the joints. Due to the isotropy of SLA printing technology and photosensitive resin, the parts are strong enough for promotion and prototyping use, although they are not suitable for end-use.

- Last but not least, the production period of printing a max size object is only less than 3 days. If we assign the work to an industrial SLA printer, it should be split into at least 2 parts and take 5-7 days; for a common SLA printer, you have to split it into at least 4 parts and spend 10-12 days.

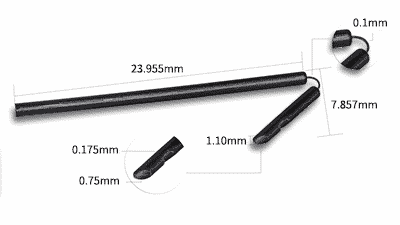

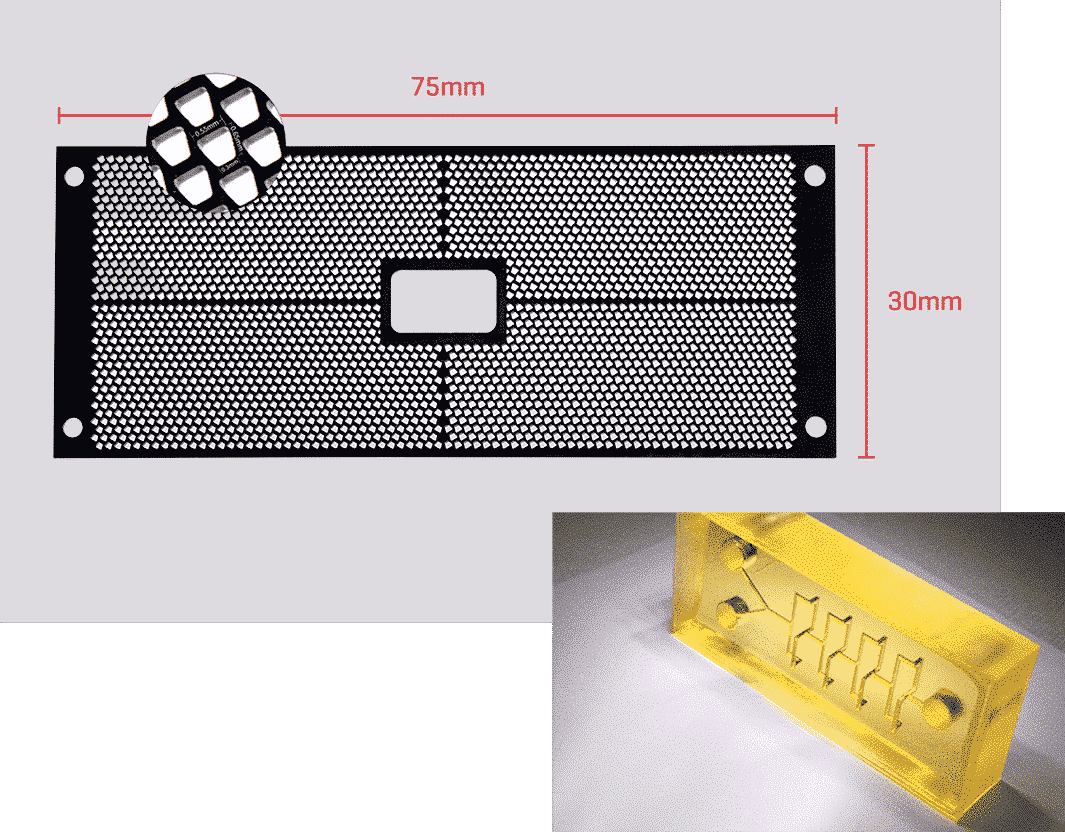

Facfox Micro-Precision SLA 3D Printing

Micro 3D printing is the optimal manufacturing process for various use cases across a wide variety of industries. The combination of ultra-high resolution, accuracy, and precision allows for more intricate, exact, and replicable parts.

- Material: Resin with various selections like generic, high temperature, transparent, tough, biocompatible, low viscosity

- Technology: SLA 3D printing – PµSL (Projection Micro-Stereolithography) technology

- Printing resolution: 2μm

- Tolerance: +/- 10um

- Layer thickness: 5μm – 20μm

- Printing height: 2mm -10mm

- Printing area: 10 × 3.84 × 2.16mm

- Application: Electrical connectors, microfluidics; micromechanical devices including valves, pumps, sensors, speakers, microphones.

The micro-precision SLA printer brings at least three advantages:

- It enables us to print objects on micro-scale, which means that SLA 3D printing is given more possibility in those cutting edge industries like medicine, optics, and electronics, etc.

- The combination of ultra-high resolution, accuracy, and precision allows for more intricate, exact, and replicable parts. It’s feasible to design accurate and complex systems, expand performance while making devices smaller.

- The quality of the printed parts can fully match the quality of high-resolution injection molding and CNC processing, but the price is much lower. Its strength in the price-performance ratio is especially outstanding for low volume production.

Conclusion

If you need to manufacture any product with an unusual size, or if you want to optimize your current production method to improve your quality, efficiency and lower the cost, do not hesitate to contact us via online support, Facebook or email! With a 20-year experienced expert team, FacFox could help you find the best solution.