The Hazleton Casting Company augments its traditional foundry operations with additive manufacturing. A new sand 3D printing system is expanding options for the foundry’s customers in areas including legacy tooling, product development and design complexity.

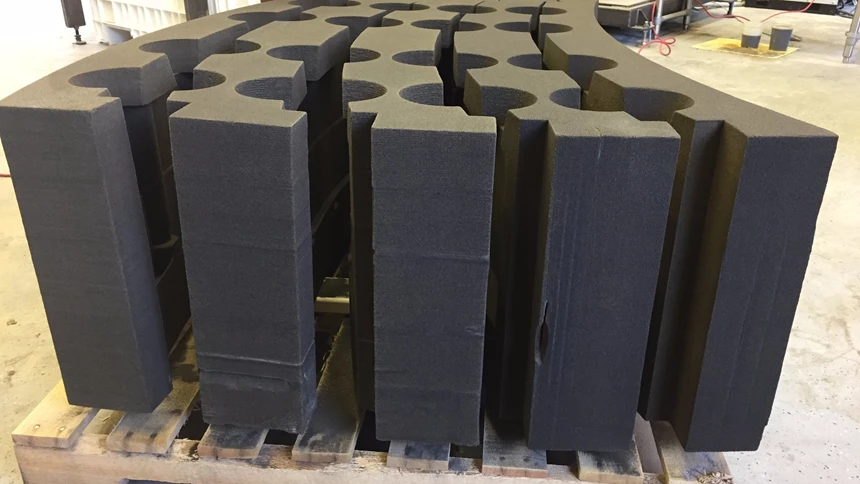

From left to right, a bucket casting produced at Hazelton using 3D-printed sand mold, as well as the 3D-printed mold sections that together were used to produce the casting.

A mechanical whir within a small warehouse adjacent to HCC is the casting call of a Viridis3D RAM123 robotic sand printer—a “game changer,” as HCC President Tony Badamo calls it. Located just a stone’s throw from the foundry furnaces, the Viridis machine prints molds and cores straight from a digital model into a bed of sand, one sweeping layer at a time, without any need for a pattern or core box, the tooling that has long been typical of industrial casting.

…AM is pushing engineers who make cast components to consider design optimization, as well driving foundries to rethink solutions to castings previously created with conventional tooling.

A Perfect Dilemma

It was only a few years ago when Hazleton began exploring additive technologies to complement its existing toolmaking capabilities, and started subcontracting with outside printing bureaus to manufacture molds and cores from customers’ digital models. But when problems arose with any given outsourced product—excessive slag, shrink defects from the alloys reacting with the environment, or mold design flaws such as improper placement of the risers—the variables were numerous enough that pinpointing a root cause was difficult at best. Was there a quality issue with the sand? Was the binder distribution from the print head consistent? Was there a defect resulting from the geometry of the mold itself?

From the customer’s perspective, of course, the onus to get it right falls squarely on the foundry. “We ran into problems where there was a lot of finger pointing,” Badamo says. “When that happened to us the first time, we knew that if we were going to be a player in this market and in this environment, we needed to get this process in-house.” HCC purchased the Viridis machine in November of 2016.

After the head of technical operations at EnvisionTec, the parent company of Viridis3D, oversaw installation of the sand printing system at HCC the following month, its first commercial print was for a pump company that contracted a small production run of five pieces. HCC was the first foundry in the country to purchase the RAM123 model, and its first job gave Badamo and his team a chance to experiment and become familiar with the system’s capabilities. Subsequent jobs have revealed efficiencies and hybrid applications with traditional foundry methods that have presented the HCC team with an interesting dilemma: which competitive advantage to exploit first.

Since much of Hazleton’s value is derived from the ability to perform small-capacity, engineered-to-order short production runs, sometimes in expensive metals, the opportunity to assist customers with product development is one of the major advantages of using sand printing as an alternative to conventional foundry tooling. For instance, HCC has contracted with a company that wants to test four design configurations for four different parts. Do the math, and that’s 16 unique castings, all with complex geometries normally requiring patterns and/or core boxes that would have been difficult to build. 3D printing allows HCC to forgo this tooling in order to let the customer test and potentially change the design.

Hybrid Casting

By printing molds and cores straight from CAD from the sand printing system, Hazleton can offer customers a production timeline of three to four weeks for a prototype or final part, rather than the three to four months typically required when patternmaking and core box machining are part of the process.

Hazleton Casting is a sister facility to the much larger Weatherly Casting & Machine Company. Primarily an iron foundry located just nine miles from Hazleton, Weatherly’s melt capacities are greater than Hazleton’s. Weatherly can combine melt capacities to 20,000 pounds, while HCC can achieve a combined 12,000-pound pour. But with the introduction of additive manufacturing (AM), the two foundries are able to partner in ways that were unprecedented before the arrival of AM at Hazleton.

At the time of my visit to Hazleton this past June, HCC was under contract to create mill liners for a power-generating company that lacked original patterns. Given the company’s short lead time, Badamo quoted the job through the 3D printer, which can create molds for casting not only for HCC but also for Weatherly’s much larger facility. By compressing the lead time, Hazleton was able to sell speed in a way it previously could not.

“It was a lead-time-specific decision,” Badamo says. “The cost is higher with the 3D-printed product, but when you add the cost of the tool, plus the cost of the part, plus the loss of production in the lead time, it’s an economic opportunity.”

But the choice isn’t either-or. Significantly, Hazleton has also learned to integrate 3D printing with its traditional foundry operations into a hybrid casting process. Using conventional tooling—a pattern—Hazleton can create a base form for a given part. Then, it can use 3D printing just for design configurational changes within the mold. For instance, during my visit, HCC was in the process of building stem patterns for a valve manufacturer, and it reduced costs by 3D printing the cores. Since the base shape was static, it made sense to build just this much using a conventional pattern.

“In this case, it is really not about variation; it’s about complexity,” Badamo says. “When we compared the cost to print versus the cost to actually build the core using conventional tooling, it was pretty close to a wash. The 3D-printed core was almost as inexpensive as the conventional product. We were able to allow our customer to forgo that tooling expense to build that core,” which otherwise might have accounted for at least 50 percent of the cost of the tooling, he says.

All the Sand That’s Fit to Print

In Hazleton’s case, the concept of flexibility goes beyond complex design geometries that 3D printing is capable of producing. Much of the sand in a mold is not in the detailed features; it’s contained in the thick, safe mass of the mold that is strong enough to support casting. Of course, time on the 3D printing system is expensive, and printing sand is pricier than foundry sand, so as each span of the print head deposited sand to build the simple mold shell wall, Badamo’s team realized that it was essentially wasting time and money. A lightbulb went off, Badamo says, and the team devised a money-saving method based on one simple philosophy: Print what needs printing, and don’t print what doesn’t. The solution? Place the mold cavity shell—without the wall—into a flask (the reinforcement tooling, typically box-shaped, used to contain molds in foundry casting) and pack it with foundry sand. That is, in the same way sand might be packed around a pattern, pack the sand instead around the complex 3D-printed form.

“That’s the panache that we didn’t have when we were outsourcing,” Badamo says. “That’s something that we saw by getting the printer in-house and in the hands of people who really know molding.”

The process hasn’t been without challenges. Even with Hazleton’s journeymen who spend 8,000 hours learning their trade before they’re truly considered a molder at HCC, none of them had ever seen a 3D-printed mold that needed to be pieced together. “We’ve printed pieces here that we thought wouldn’t be a big deal until we got them (to the foundry), and we had men scratching their heads,” he says. “We have a pump casing that we printed all of the components to, and there’s a core that has a feature on it that needs to be indexed properly. We keyed the index the way we would for a core made from a core box, but that meant we put the key in the wrong spot for the 3D-printed version. We got around it and salvaged the part, but that was a learning experience.”

The Flash Drive Warehouse

For all of the new capabilities that sand 3D printing brings to Hazleton’s foundry operations, the team still has to work with the designs that customers bring to them. While HCC is capable of providing feedback and design suggestions to its customers, Badamo’s team members are not design engineers themselves. That said, AM is pushing engineers who make cast components to consider design optimization, as well driving foundries to rethink solutions to castings previously created with conventional tooling.

When a pump company ordered a set of castings based on 25-year-old conventional tooling, Hazleton encountered problems that stemmed from complications of the core shape. The original pattern was made in three pieces with narrow gaps and joints that would traditionally be sealed in the open air. When the original product was manufactured, the tooling was new and the pieces fit together seamlessly. Now, years later, the wooden tooling had warped, creating gaps between the pieces that allowed for metal penetration during the casting. Not only that, but the penetration itself was surrounded by metal, leaving no practical access for machining the error away.

Then, another lightbulb went off: Print it all with one body and eliminate the flashpoints. Indeed, this capability of AM—consolidating assemblies—shows great promise across numerous industries, particularly aerospace and automotive, where various fasteners and assembly steps can become obsolete through AM. In the case of the pump casting, the advantage was avoiding potential casting errors resulting from poor fit in the tooling assembly. The idea worked. “We made three of them and shipped them out,” Badamo says. “Last we heard, they were in assembly and testing, and everything is going really well.”

Badamo says that in his day-to-day interactions with customers, the majority don’t yet grasp the efficiencies offered by AM. They know what it is, he says, and are familiar with the general processes involved, but don’t yet understand or appreciate its capabilities. Yet then there are some customers at the edge of the envelope—customers with legacy products that have made a determination that they simply don’t want to own pattern samples.

One pump manufacturer is one such example. While the company has a pattern inventory that goes back to its founding more than 100 years ago, it concluded that housing those patterns no longer makes sense. The manufacturer is in the process of modeling every product, Badamo says, and looking at 3D direct-to-print molds (in combination with disposable patterns also made with 3D printing) as a means of phasing out the storage inventory entirely. The goal? To have a century’s worth of pattern inventory stored on a flash drive. If that isn’t progress, it’s hard to say what is.