In the rapidly evolving world of full-color 3D printing, WJP (White Jet Process) technology is emerging as a strong contender. Developed by the Chinese brand Sailner, WJP is positioned to compete with industry leaders like Mimaki, offering advanced capabilities in full-color, multi-material, high-precision 3D printing.

What is WJP 3D Printing?

WJP is a micro-droplet jetting photopolymerization process that merges digital inkjet imaging with photopolymer deposition. The printer sprays thin layers of photosensitive resin, which are then immediately cured with UV light. Layer by layer, the build platform lowers with extreme precision, and the print head continues depositing material until the final object is complete.

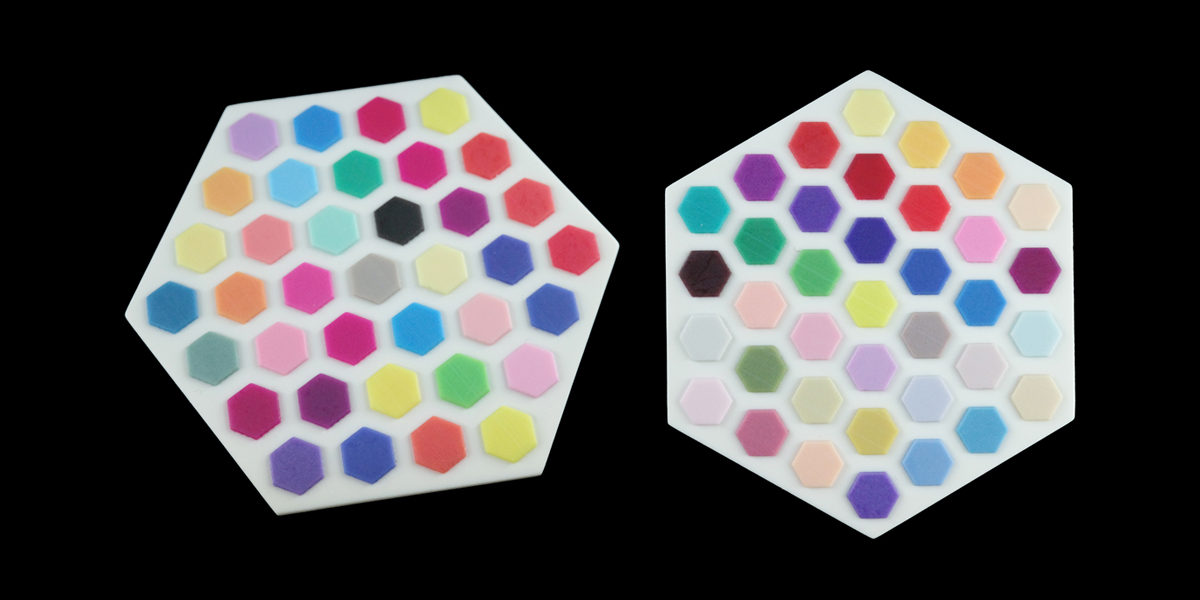

What sets WJP apart is its white ink filling technology, which enables vibrant full-color output by using color management software and multi-channel material pathways. Colors are mixed directly at the voxel level, allowing for smooth gradients, fine color transitions, and even adjustments in material hardness across a single print.

Key Advantages of WJP Technology

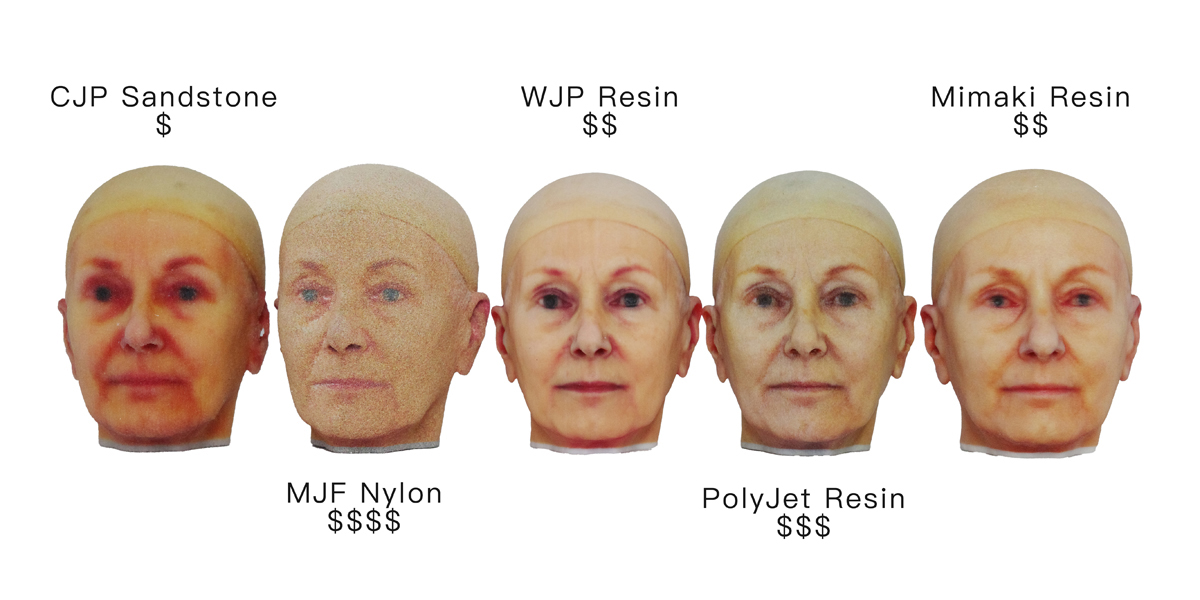

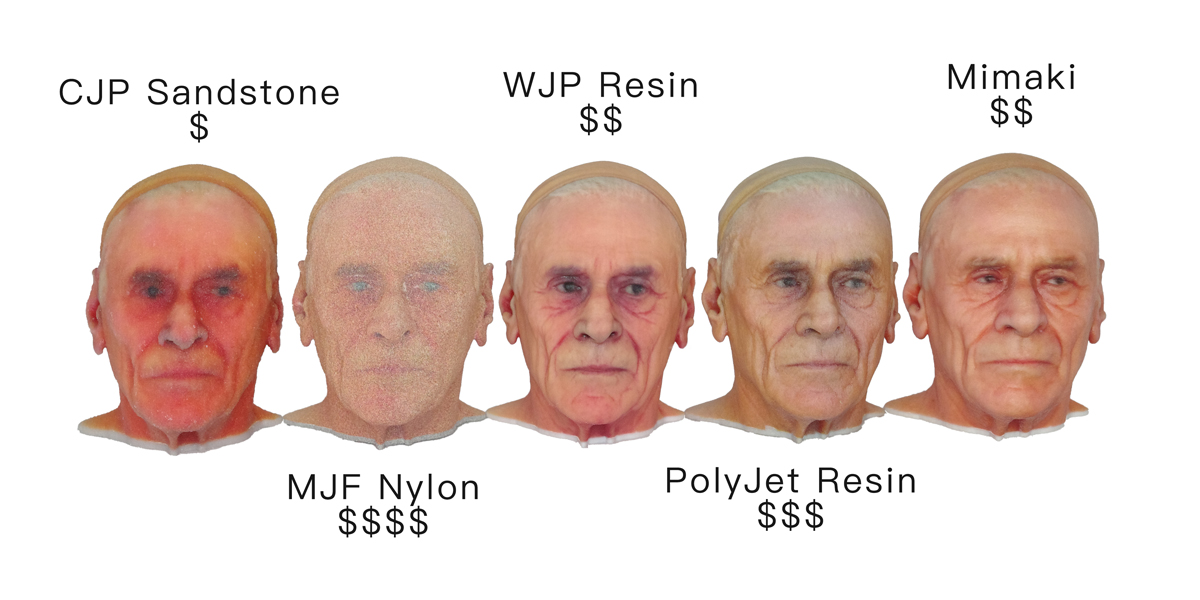

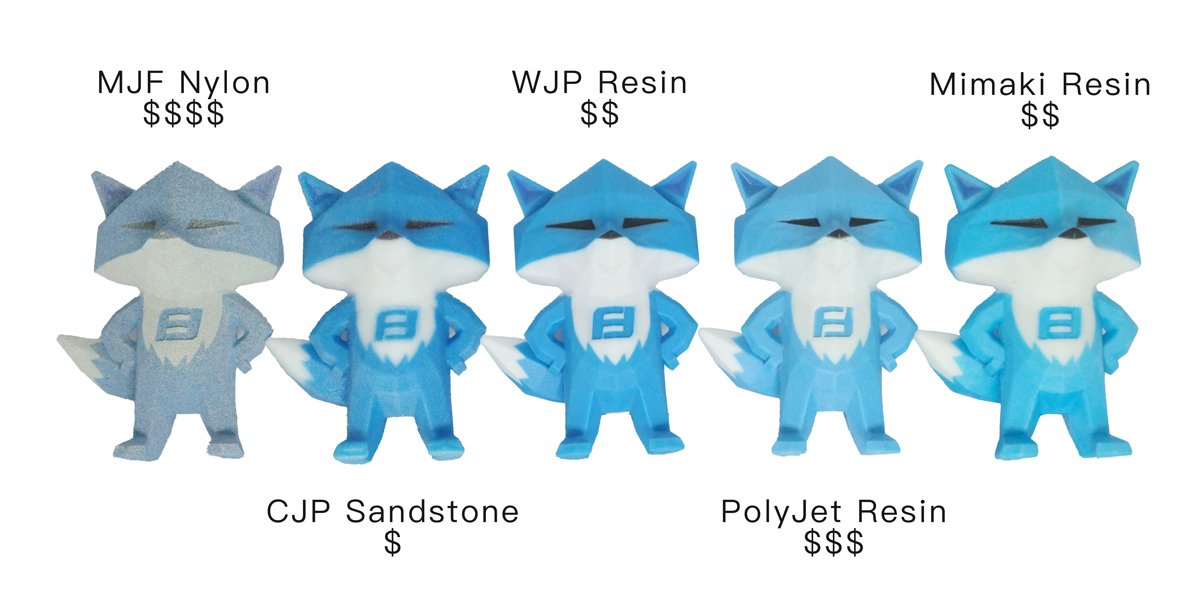

- Full-Color Realism: With advanced color mixing algorithms and the addition of white ink, WJP delivers highly detailed, lifelike color reproduction. Even miniature figurines can capture intricate color details without additional painting.

- Multi-Material Capability: WJP supports a wide range of photopolymer materials, including rigid, flexible, transparent, opaque, ABS-like, nylon-like, heat-resistant, and even biocompatible medical-grade resins. This versatility makes it suitable for industries ranging from collectible manufacturing to medical modeling.

- High Precision & Resolution: WJP achieves resolutions up to 14μm layer height and 1800 dpi, producing extremely fine surface details with minimal need for post-processing.

- Efficient Production: Thanks to its high-speed piezoelectric printhead with up to 3840 nozzles, WJP can quickly produce small-batch, highly detailed parts with excellent consistency.

Application Scenarios

WJP technology finds applications across multiple industries:

- Medical Models: Anatomical models, surgical training tools, and medical guides using biocompatible materials.

- Collectibles & Figurines: Lifelike figurines, character models, and full-color miniatures.

- Prototyping & Product Design: Functional prototypes with realistic color and material properties.

- Educational Models: Detailed teaching aids and demonstration tools.

Material Safety & Properties

WJP printing materials are designed with both performance and safety in mind. They offer:

- Low toxicity and low irritation

- UV sensitivity for rapid curing

- Low viscosity for smooth jetting

- Minimal shrinkage to ensure dimensional stability

Design Guidelines

- Maximum size: 390×340×240mm

- Minimum size: 5×5×5mm

- Tolerance: ±0.2mm

- Wall thickness: From 1mm (small parts) up to 3mm (large parts)

- Text details: As fine as 0.4mm for color-mapped text

- Holes & threads: Precise specifications ensure functional features like threaded holes and press fits.

| Design Feature | Specification |

|---|---|

| Build Size | Max: 390 × 340 × 240 mm Min: 5 × 5 × 5 mm |

| Precision | ±0.2 mm (0.3%) |

| Minimum Wall Thickness |

|

| Text (Embossed/Debossed) | Full-color: Min width & depth: 0.8 mm Full-color spray-painted: Min width & depth: 2 mm |

| Text (Color-mapped) | Full-color & spray-painted: Min width: 0.4 mm |

| Threads | Pitch: 1.5 mm, Angle: 60° |

| Assembly Clearance | Minimum gap: 0.2 mm |

| Channels (Holes) |

|

| Hole Tolerance | ±0.1 mm ~ ±0.2 mm |

| Columns/Posts |

|

FacFox’s WJP 3D Printing Service

At FacFox, we are excited to bring you the full capabilities of WJP full-color 3D printing. Whether you need highly detailed figurines, complex multi-material prototypes, or precise medical models, our WJP service delivers unmatched color accuracy, fine detail, and production efficiency. Combined with our professional support and competitive pricing, FacFox helps turn your creative designs into vivid reality. Contact us today to experience the next level of full-color 3D printing with WJP!