The additive manufacturing of pure copper has made remarkable progress in recent years, transitioning from a technically challenging concept to a commercially viable solution for thermal management systems. Known for its superior thermal and electrical conductivity, copper is a preferred material for components such as heat exchangers, heat sinks, and vapor chambers. However, its optical reflectivity and high thermal conductivity historically posed serious challenges for laser-based 3D printing processes. Recent developments, both in materials and processing technologies, have addressed these issues and significantly expanded the possibilities of copper-based additive manufacturing.

Challenges in Additive Manufacturing of Pure Copper

Copper’s physical properties, while advantageous for thermal performance, present difficulties for conventional laser powder bed fusion (L-PBF) and other fusion-based 3D printing technologies. The primary issues include:

High Reflectivity

Traditional infrared lasers are poorly absorbed by copper, leading to low energy coupling and inconsistent melting.

High Thermal Conductivity

Heat is rapidly dissipated during the laser melting process, making it difficult to maintain a stable melt pool.

Porosity and Incomplete Fusion

These issues lead to low-density parts that are unsuitable for applications requiring high thermal or electrical performance.

These limitations previously restricted the use of 3D-printed pure copper in critical industrial applications.

The progress from 2023 to 2025

In 2023, a comprehensive review of additive manufacturing techniques for pure copper highlighted several key advancements:

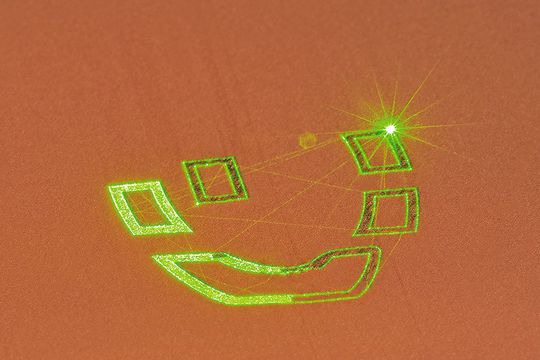

Use of Green and Blue Lasers

By shifting to shorter wavelengths (515 nm for green and 450 nm for blue), laser absorption was significantly improved, allowing for higher part density and surface quality.

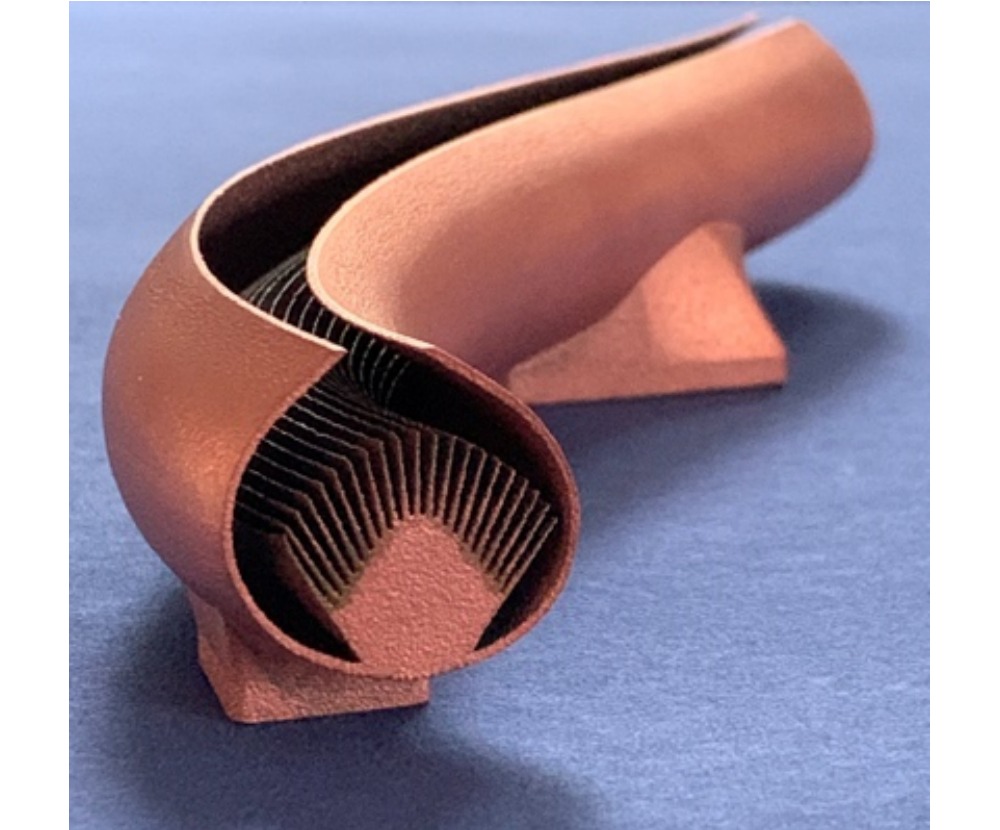

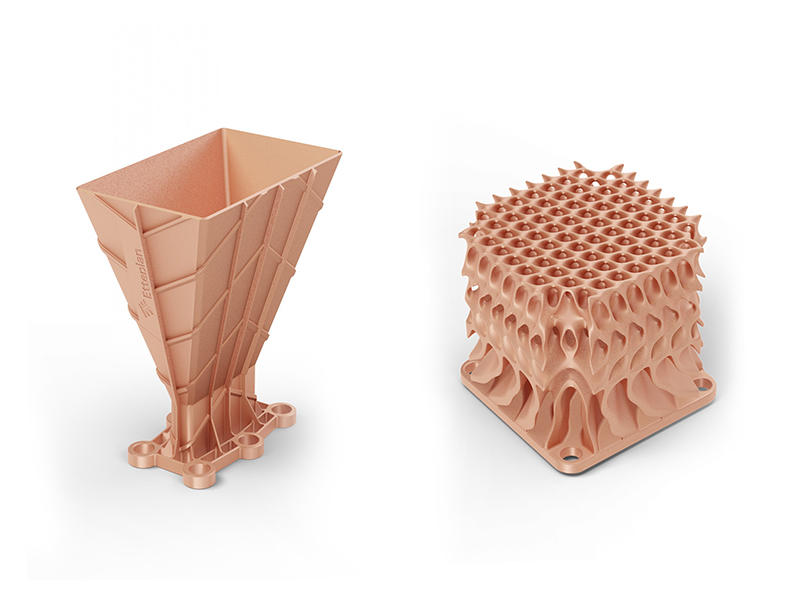

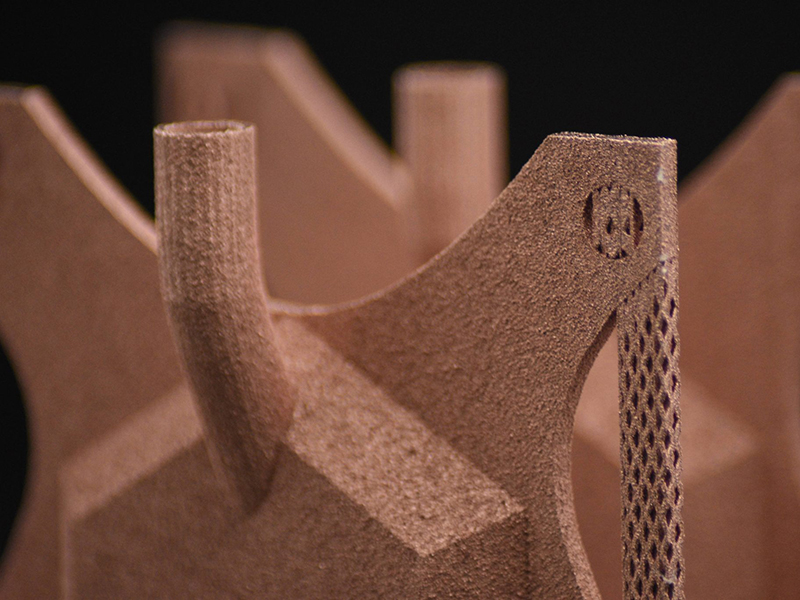

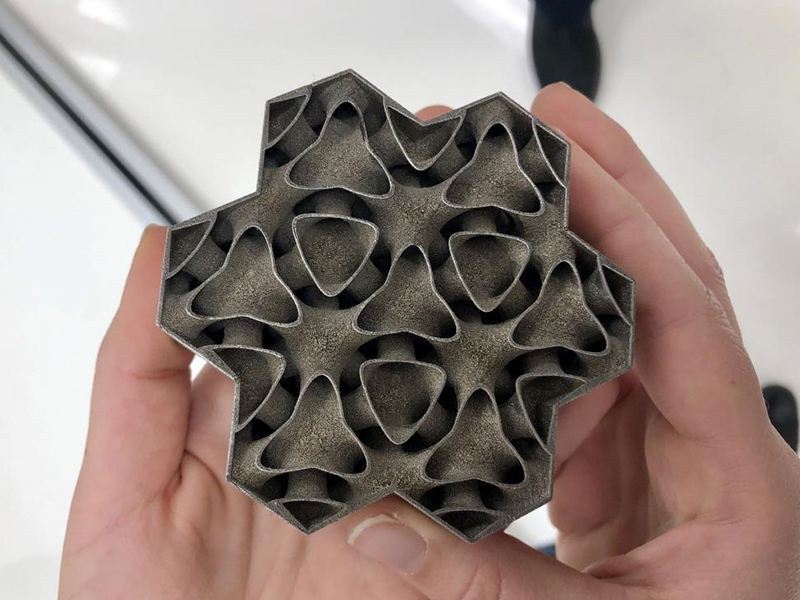

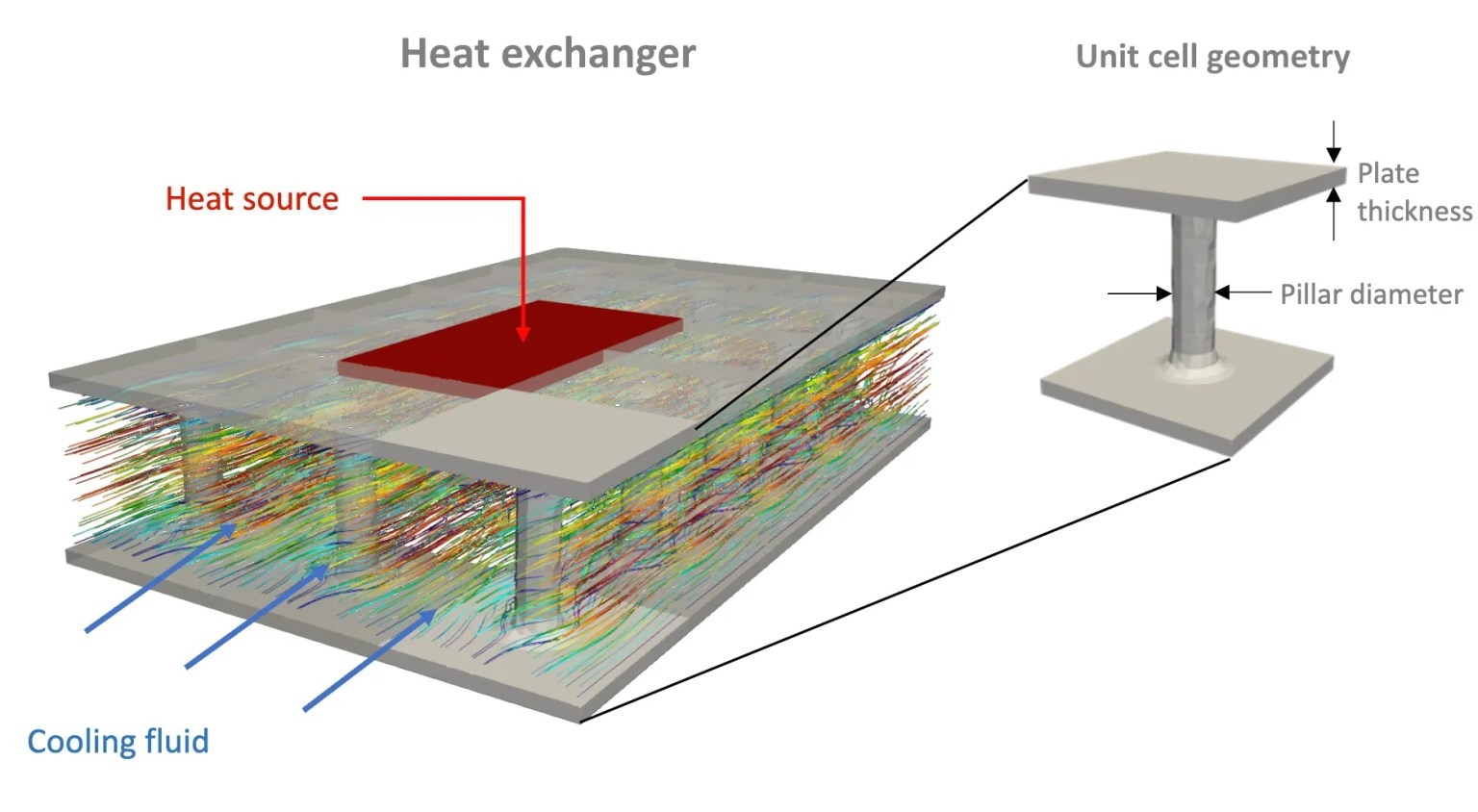

Geometrically Complex Designs

With the help of topology optimization, porous foams and lattice structures were created to enhance the surface-area-to-volume ratio, improving heat transfer performance.

Technique Comparison

- L-PBF showed the most promise in achieving dense, complex copper parts.

- Binder Jetting offered scalability but at the cost of part density.

- Sinter-based Methods (e.g., vat photopolymerization and extrusion) allowed high-resolution geometries but faced challenges in final part consolidation.

The report emphasized the potential of these methods in improving the performance of thermal management devices and stressed the need for further process optimization and standardization.

Building on the foundation laid in 2023, the years 2024 and 2025 have brought several noteworthy innovations that further improved the feasibility and quality of 3D-printed pure copper components.

Material Innovations

-

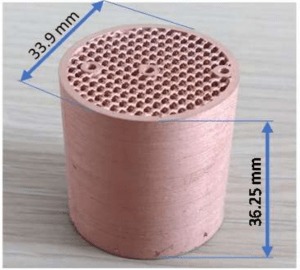

INFINITE POWDER Cu 01: Developed by Infinite Flex, this powder supports selective laser melting and enables over 99.9% part density, tensile strength exceeding 220 MPa, and elongation above 24%. It is compatible with widely available industrial printers, making it an attractive choice for scalable production of heat exchangers and RF components.

-

Digital Metal’s Cu Powder: Designed for binder jetting, this powder also achieves 99.9% purity, offering high conductivity and the ability to produce fine geometries in larger quantities.

Processing Enhancements

-

Green Laser Systems: Addireen introduced new green laser technologies capable of printing features as small as 80 microns, significantly enhancing detail resolution in complex thermal management components.

-

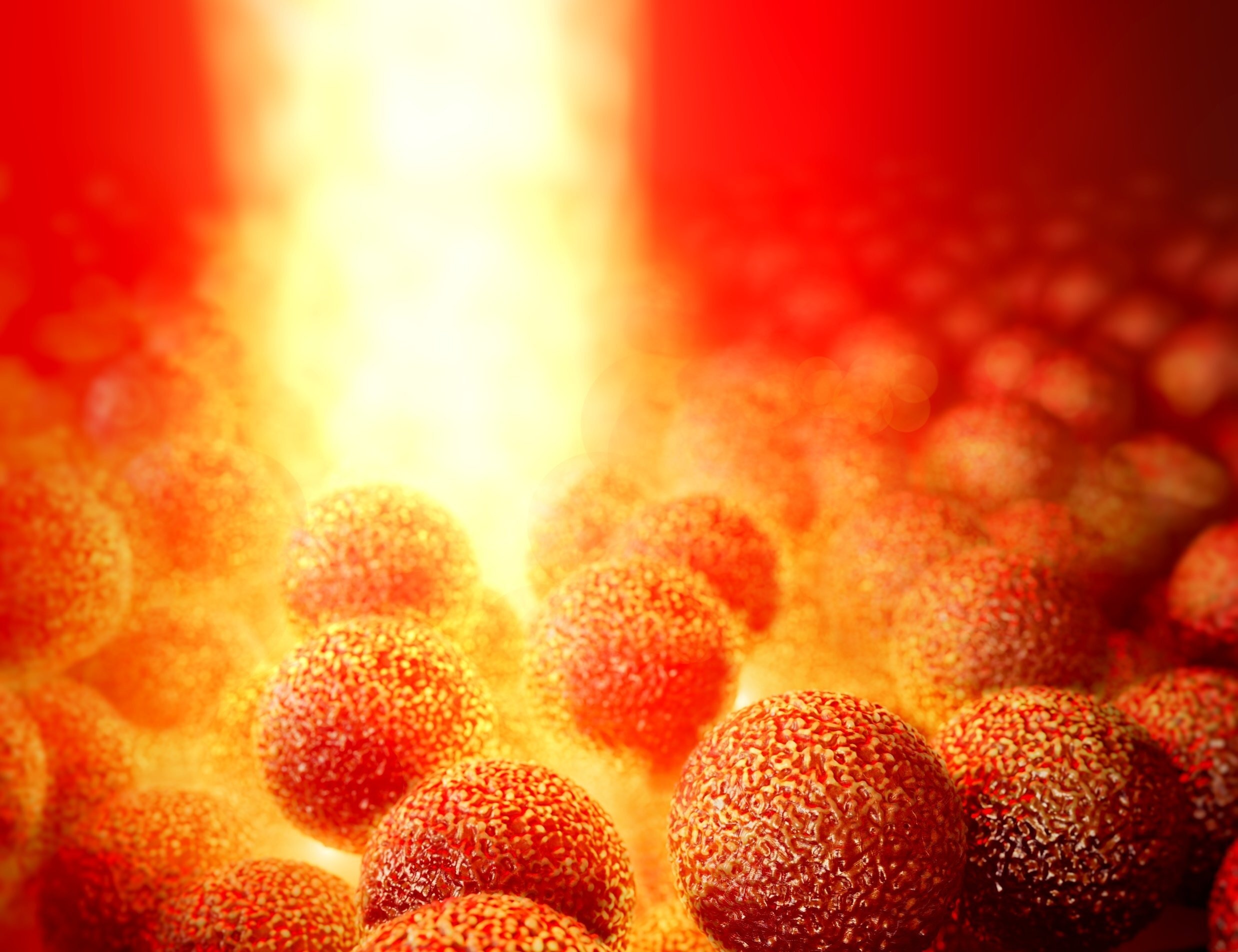

Surface Nanotexturing: A process developed by Lawrence Livermore National Laboratory improved laser absorptivity of copper powder through nanoscale surface texturing, enhancing energy efficiency and reducing defects.

Addireen developed green laser systems that significantly improve the absorption of laser energy by pure copper powders, achieving part densities up to 99.8% and enabling the fabrication of components with fine features as small as 0.08 mm. Image source: Beamler

A wet chemical etching process that creates nanoscale textures on copper powders, enhancing laser absorption by up to 70%. Image source: phys.org

Application-Specific Developments

-

Advanced Cooling Solutions: Alloyed and Infinite Flex jointly developed cooling plates with embedded lattice structures for data centers and high-performance electronics, improving heat dissipation and mechanical stability.

-

Compact Heat Exchangers: A collaborative project led by GE Research, in partnership with Oak Ridge National Laboratory, utilized additive manufacturing to design compact, highly efficient heat exchangers for power generation.

-

Model-Free Design Optimization: Research groups introduced multiscale modeling frameworks that eliminate the need for computational fluid dynamics (CFD) simulations in thermal component design, streamlining the engineering workflow.

Alternative Manufacturing Techniques

-

Material Extrusion (MEX): Researchers at Politecnico di Milano successfully fabricated lattice structures with high thermal performance using copper-filled filaments. This opens up new possibilities for low-cost production of catalytic and cooling elements.

-

Piston-Fed Extrusion for Small Parts: Recent studies demonstrated the feasibility of using extrusion-based technologies to fabricate small, intricate copper parts with properties comparable to those produced by high-end fusion systems.

Outlook and Industrial Relevance

The recent advances in pure copper 3D printing technologies mark a turning point for its practical use in thermal management applications. With enhanced material properties, improved printing resolution, and broader compatibility with standard industrial equipment, additive manufacturing now offers copper solutions that are:

-

Highly Efficient: Custom geometries allow for superior heat transfer and compact designs.

-

Cost-Effective: Improved scalability through binder jetting and extrusion techniques reduces manufacturing costs.

-

Application-Ready: Emerging industries, particularly in energy systems, computing, aerospace, and power electronics, are rapidly adopting copper-based 3D printing for prototyping and end-use parts.

Contact FacFox for pure copper printing!

The 3D printing of pure copper has evolved from a technical challenge into a mature and scalable manufacturing strategy. Continued innovation in laser technologies, powder development, and design optimization is expected to further expand its adoption. As additive manufacturing becomes a mainstream method for producing high-performance thermal components, pure copper stands out as a key enabler of efficient, compact, and customized cooling solutions.

For companies and developers seeking to leverage these advancements, FacFox offers expert 3D printing services, including SLS and metal printing with copper-compatible technologies. From prototype to production, FacFox provides technical guidance, material selection, and manufacturing support to bring high-performance thermal solutions to market.