Building your own filament dryer or dry box is simpler than it seems. Read on to learn how to DIY a filament dry box!

You may have heard a crackling sound from your filament as it was extruded through the nozzle, or witnessed it stringing between layers. These small details point to the larger issue of wet filament. Most plastics used in 3D printing are hygroscopic, which makes them more prone to absorb and retain moisture from the air. Although it can’t be seen with the naked eye, moisture affects the mechanical properties of the filament material, thus affecting your print quality.

The visible stringing and bubbling, combined with the audible crackling, are due to water molecules in the plastic evaporating out of the heated nozzle. Because this alters the diameter of the filament as it passes through, your prints are at risk of other issues such as inconsistent extrusion, poor bed adhesion, and low durability.

The most economical solution to this problem is to protect your filaments with a dry box. If the damage is already done, you can actively dry your filament with a heated dryer. The goal of both is to keep the filament free of moisture in a temperature-controlled environment. While a dryer actively expels the moisture with a heating element, a dry box passively prevents further moisture absorption by using desiccants. In this article, we’ll be reviewing the general guidelines for building both types on your own.

What to Think About

Building your own dryer or dry box sounds daunting if you don’t know where to start. Like any other project, it’s helpful to come up with a plan based on your needs and expected outcomes.

When planning out the build, there are several design considerations you need to take into account. You need to think about the space you have available for a dryer or dry box and how complex you want this project to be. And although it’s ideal to keep all your filaments as dry as possible, some materials are more sensitive to moisture than others and should be prioritized. Therefore, there are a few key things to think about.

YOUR CURRENT SITUATION

Do you already have filament in need of dehydrating? Filament that needs to be actively dried determines whether or not you should use a heater or passive dryer. All filaments benefit from being stored with desiccant, while specific filaments such as nylon, PETG, and TPU should be dehydrated using heat when needed.

YOUR COMMONLY USED FILAMENT TYPES

How hygroscopic are your filaments? Finding out how moisture-sensitive your filaments are helps you to determine the potential conditions your box will have to meet to maintain those filaments. PrintDry, a manufacturer of dryers, has created a helpful table with specific temperatures and drying times for 12 different materials.

CAPACITY

How many spools need to be kept dry? One major benefit to building a dry box is that you’re only limited by the size of your box. The larger the box, the more filament spools you can store. If you opt for a dryer, scaling up gets more complicated, but there’s always the option to buy an affordable food dehydrator to dry up to two spools at a time.

CONVENIENCE

Do you want to feed filament to your printer directly from the box? If you want to keep filaments in the box while simultaneously using them, you’ll need to cut a hole in the box for the filament to pass through and find a way to let the spool roll. Because of this, consider how you’ll maintain the airtightness of the box and keep the spool rolling in place. If you’re happy to keep your box as pure storage and remove filaments for use, then really all you need is an airtight box and a few packs of desiccant!

Getting Started: Basic Materials

Now that you’ve come up with a build plan, we can discuss the basic materials that are constant in any dryer or dry box. These include:

- A storage method, usually in the form of a clear airtight plastic box, enclosure, or vacuum-sealable bag. It should be big enough to hold at least one spool. Be sure to measure the dimensions of your filament spools for reference, and consider how many you want to store and how much space you have available.

- A spool mount that holds your spools in place to dry uniformly. These can be rollers, rods, or even a custom 3D printed fixture. Depending on your chosen storage container, a mount may not be necessary, for example in a round container.

- A drying element that is either active or passive. If active, it will be a kind of heat source such as a heating fan or food dehydrator. If passive, desiccants such as silica gel, salt, or molecular sieve are used.

At a minimum, you can build a dry box with off-the-shelf components without modifying anything. Depending on your design considerations, there are optional components to upgrade your box, such as:

- Tools to cut holes in your box. This can range from a power drill to a utility knife, as long as it can cut through hard plastic without cracking it. Be sure to wear protective equipment such as safety goggles or gloves as appropriate.

- Tubing is required if you choose to feed your filament directly from the box to your printer. Ideally, PTFE tubes are threaded into the hole in your box (or through an adapter) to feed your filament while keeping the box airtight. As an extra advantage, this will protect your filament from the outside environment even between the box and printer. Note that the size of the tubing depends on the diameter of your filament.

- 3D printable parts if you’d like to design custom parts for your box, like a spool mount or box-to-Bowden adapter.

- Sensors to monitor the internal conditions of your box. The most commonly used sensors measure humidity, temperature, or both.

Basic Assembly Tips

Using the above basic materials, the steps to build a DIY dryer or dry box can include filling an airtight box with desiccant and placing the filament inside, storing filament in a food dehydrator and setting your desired temperature, or vacuum sealing filament in a bag with desiccant.

However, these assembly tips are applicable if you choose to modify or upgrade your materials:

- Conduct fit/motion tests: Dry boxes that will feed filament from box to printer require smooth rods, rollers, or even bearings to ensure the spool rotates smoothly. When your mounting system is assembled, place a spool on it to simulate the feeding process.

- Think twice, cut once: Ensure the holes you cut or drill aren’t too big. Consider drilling a slightly smaller pilot hole in the initial run, and then conduct a fit test. If the hole is still too small, you can progressively make the hole bigger and repeat the fit test until you achieve the perfect size.

- Test for consistent dryness: If you choose to include sensors, test them out throughout the build to verify that the inside of your enclosure is dry and temperature-controlled.

DIY Options

There are many DIY projects that have been tested by the 3D printing community to prove their effectiveness. More importantly, the DIY approach allows you to customize your build however you see fit. We’ve compiled a list of some standout projects for your inspiration.

In addition to the builds we’ve featured here, some classic dry box projects include Modern Hobbyist’s simple box with silica beads, Becky Stern’s four-spool DIY dry box, Thomas Sanladerer’s spool-winding storage solution, and the Anybox designs from Anybot. Active drying is less common as a DIY project, but there’s Tinkerman’s modded food dehydrator and Kevin Lee’s unique bucket dryer as examples.

HANDY_BEAR’S IKEA SAMLA DRY BOX

This is the classic storage box conversion, with space for four spools that feed directly to your printer.

- Approximate cost: $70

- Complexity: Medium

- Number of spools: 4

- Where to find it: Instructables, YouTube

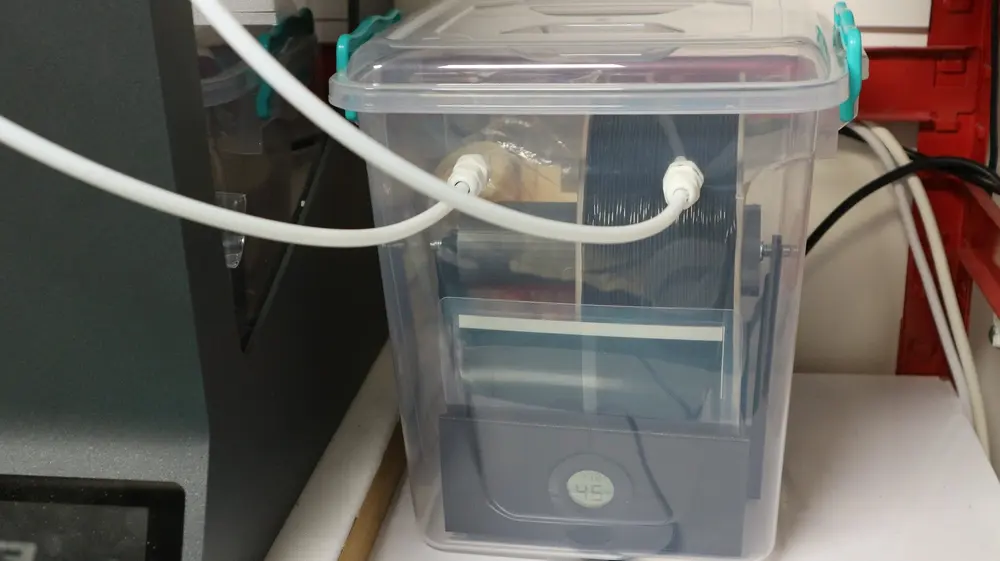

RICHARD HORNE’S HEATED DRY BOX

This project improves on the standard desiccant dry box by adding a heating element for active drying.

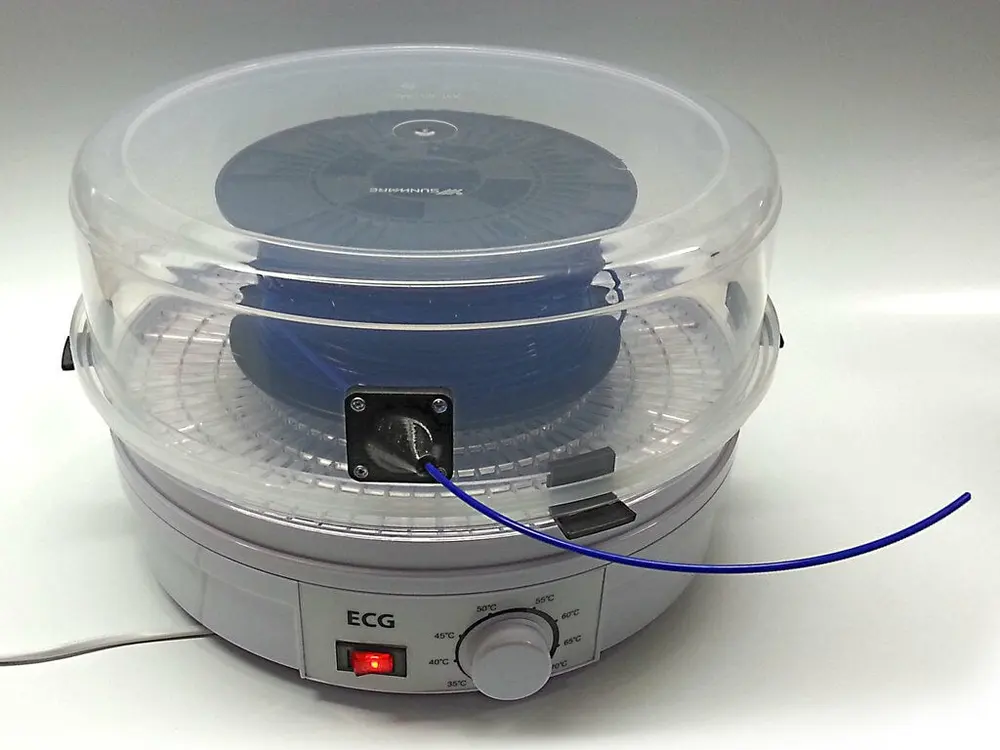

BREAKS’N’MAKES’ CONVERTED FOOD DEHYDRATOR

Rather than rigging up your own heater, this project allows you to print directly from a food dehydrator!

- Approximate cost: $65

- Complexity: Low

- Number of spools: 2

- Where to find it: YouTube

Commercial Options

For almost every need, there’s a solution on the market, and filament drying is no exception. As a result, there are also many off-the-shelf dryers and dry boxes available for purchase.

Dryers

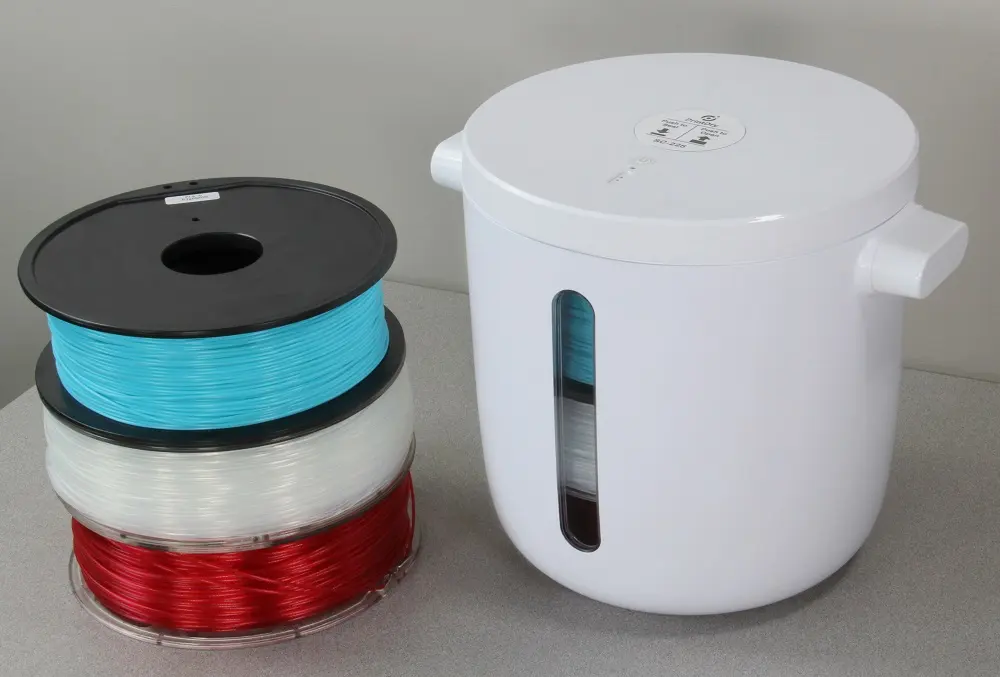

SUNLU FILADRYER S2

Sunlu’s second-generation FilaDryer is a compact device to dry one spool of filament. It has different drying modes for different materials and reaches an unusually high temperature of 70 °C.

- Approximate cost: $80

- Number of spools: 1

SOVOL SH01

The SH01 has adjustable temperature and time settings and can feed directly to your printer. It can dry for as long as 12 hours at temperatures up to 50 °C.

- Approximate cost: $60

- Number of spools: 2

COMGROW FILAMENT DRYER

This is a basic filament drying option with room for two small spools of filament or one larger spool. When not actively drying, the sealed chamber makes this suitable for long-term filament storage, too!

- Approximate cost: $60

- Number of spools: 2

Dry Boxes

POLYMAKER POLYBOX II

Polymaker’s PolyBox is a stylish dry storage solution that can house spools up to 3 kg. The built-in humidity sensor helps you monitor the condition of your filament.

- Approximate cost: $70

- Number of spools: 2

PRINTDRY SMART VACUUM FILAMENT CONTAINER

Rather than just using desiccant to create a dry environment, the PrintDry Smart Vacuum container creates an airless space to store up to three spools of filament. As you might be able to guess from the name, PrintDry offers a range of filament drying solutions including dryers and individual storage containers.

- Approximate cost: $120

- Number of spools: 3

HYDRA NAUTILUS BOX

The Nautilus Box provides storage for one spool of filament and is intended to be used while printing to keep your filament in good condition.

- Approximate cost: $90

- Number of spools: 1

- Where to find it: Hydra Research

Final Thoughts

While the commercial alternatives offer convenience and low complexity, most off-the-shelf boxes have a maximum capacity of two spools and are difficult to expand. They also don’t always allow you to feed filament from the box to the printer and instead are intended as standalone drying solutions. Purchasing multiple commercial boxes will ultimately cost much more than a single, large dryer or dry box.

If budget isn’t an issue and you need to dry your filaments immediately, the commercial options are certainly easier. However, if you’re on a budget or have specific requirements for drying your filament, building your own offers the most flexibility for the price.

Whichever way you go, a dryer or dry box will prove beneficial to your 3D printing workspace. Not only does it extend and recover the shelf life of your filament, but organizes and protects your spools from outside debris. When it comes to deciding how to approach it, the choice is yours.