3D printing concrete furniture may seem like a futuristic concept, but it may be coming soon to a living room near you thanks to the collaboration between designer Philipp Aduatz and the concrete 3D printing specialists at incremental3D.

Gradient Furniture Collection

The 3D printed Gradient Collection consists of the Gradient Fauteuil, the Gradient Stool, the Gradient Bench (large and small), and the Gradient Vase. In addition to offering the collection for sale, Aduatz has thoroughly documented both the design philosophy as well as the design process on his website for those who are interested in learning more about this unique printing process.

In addition to the design freedom afforded by the additive manufacturing process, the ability to directly 3D print objects using concrete also reduces the need for manufacturing-adjacent costs such as molds, tooling, fixturing, and more. This collection of furniture offers a glimpse into the future of manufacturing where objects can be created quickly and efficiently with minimal costs associated with incremental changes that would be otherwise cost-prohibitive to manufacture.

Concrete 3D Printing

The Gradient furniture collection uses a unique printing process developed in collaboration with incremental3D, an Austrian additive manufacturing team that is focused on concrete 3D printing. The mechanical printing process used by incremental3D is a modified version of the Fused Deposition Modeling style of 3D printing used by many desktop printers. From a glimpse of the picture, we could assume that an industrial-grade robotic arm (SCARA) was involved in the 3D printing process. Instead of depositing layers of plastic that have been melted from a filament-based feedstock, the incremental3D system extrudes large layers of concrete that are fused during the printing process.

Philipp Aduatz has collaborated with incremental3D to develop a dying process that works in parallel with the printing process that gives the final printed part a gradient of color. This gradient of color is the inspiration behind the name of the collection, and draws inspiration from image processing.

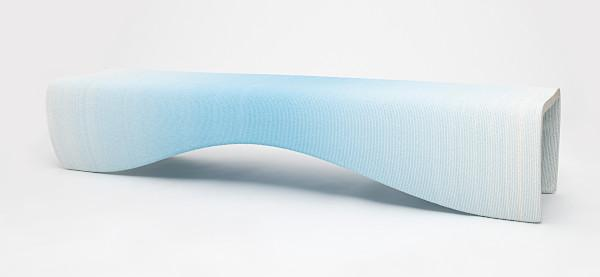

The Gradient Bench Large

The Gradient Bench Large is an excellent example of the exciting potential of this style of 3D printing. Measuring 230 x 56 x 45 cm (90.6 x 22.0 x 17.7 inches), this bench would be an impressive 3D print in and of itself, but it becomes truly note-worthy when considering the planning and processing required to achieve the gentle symmetrical gradient of color present throughout the model. The bench utilizes a steel reinforcement to add tensile strength to the concrete and is available in a limited edition of 50 pieces in red, blue, beige, green, and black.

Additional Information

Philipp Aduatz has released a video on YouTube that documents the production of the Gradient Collection and shows the work done by the incremental3D team on concrete 3D printing. The unique dying process can be seen in this video as the concrete is extruded and dyed simultaneously. This video also shows the Gradient Vase; a model with polygonal design intent that has been smoothed using a subdivision modeling process to give it a gentle gradient surface between faceted and smooth.

- Functional Art by Philipp Aduatz (Official Website)

- Philipp Aduatz’s 3D printed gradient furniture collection is among the finalists in the 3D Pioneers Challenge (3DPC 2021)

By creating a 3D printed structure using a specialized machine and locally sourced materials, is a clear demonstration that this style of construction is no longer simply an idea, but a practical reality that can be produced and reproduced.

Author: Andrew Sink