3D printing in medicine is becoming widely adopted due to the technology advancement. The ability to customize and produce test models makes 3D printing invaluable in surgery planning, dentistry, and prosthetics, for example. There are more sophisticated applications of this technology that medical professionals are starting to explore. What used to be the work of imagination, nowadays gets implemented in practice.

Medical 3D Printing Brief History

3D printing was first patented in early 1980. And in the 90s 3D printing was used in medicine. The first 3D prints in medicine were made for surgery planning.

CT Scans & Prints for Surgery Planning

CT (Computer Tomography) scanning for further 3D printing is one of the common practices.

The Mackay Hospital in Queensland, Australia, is known for its modern facilities and the use of the latest technologies. It came as no surprise that 3D printing was introduced into their research. Doctor Jonathan Davies gives his feedback about using a 3D printer in their work.

We are able to print fractured bones or bony deformities which gives the surgeons a tactile model to imprint the bony architecture in their memory. This makes surgery much easier and increases the surgeons’ understanding of the geometry. We can also use the models to trial implants and metalware so that we know what equipment will work best for fixing fractures.

Doctor Davies highlighted that saving operating time due to the surgeons getting familiar with the procedure/architecture in advance is the great benefit of using 3D printing. Furthermore, seeing finished models helps the patients to understand the nature of the future procedure.

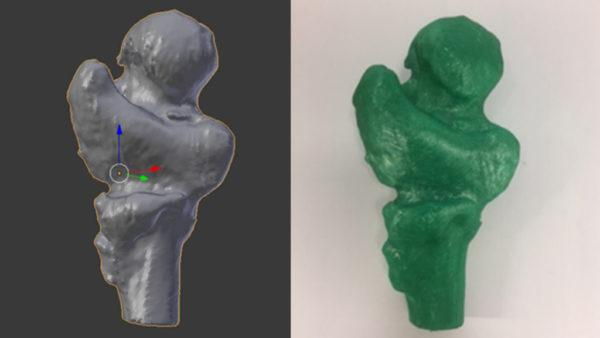

The pictures above feature the scanned bones awaiting surgery together with their 3D printed replicas: fractured femur and calcaneus bones.

3D printing from CT scans can be possible even for casual desktop 3D printer users at home. Check the YouTube video below to learn how Andrew Sink turns his own spine CT Scan into an STL file thanks to Invesalius open source software and then he 3D prints it on the Original Prusa machine.

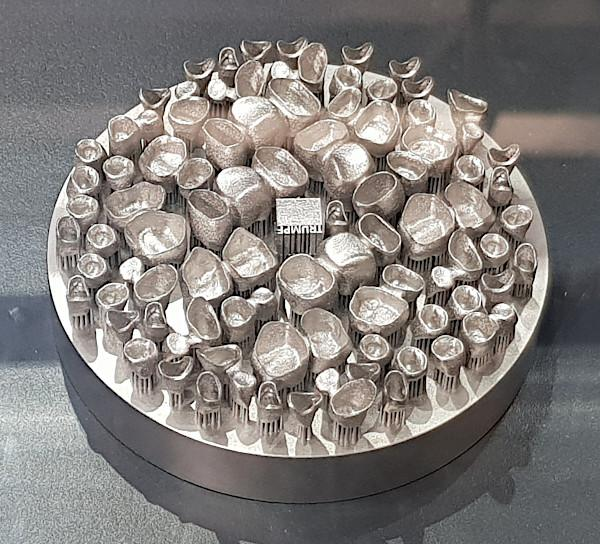

So where exactly 3D printing helps in Dentistry?

In creating all sorts of dental models: braces, bridges, aligners, surgical guides, full dentures, temporary restorations, permanent crowns, etc. If previously patients had to bite a gooey, a specific clay, which hardens into a mold, and then the mold helps to design some of the dental models, now Intraoral scanning and 3D printing do the job more precisely and quicker.

Apparently Intraoral scanner price (between 10-20k at the moment of writing this post) is one of the biggest drawbacks for the small in-house labs at the moment. Not only because the scanner is expensive but certain skills/training are required to achieve precise 3D scans. SLA, DLP, or SLS 3D printers, which are mostly used for dental prints, are inexpensive.

While less human contact is encouraged during the COVID pandemic it may serve as an accelerator for digital dentistry.

3D Printed Prosthetics

The ability to 3D print highly customized objects made prosthetics much more affordable, comfortable, functional, and attractive. More and more prosthetic arms and legs are getting 3D printed. These also have added functionalities that traditional prosthetics have never had before. Arms have more types of grip, for example.

It is worth of special mentioning the Openbionics project.

At the end of the last decade, Openbionics reached out to the Hollywood and Disney companies and obtained permission to use the copyrighted designs for their prosthetic arms for kids. A so-called “Hero Arm” may bear a design of the superhero from a popular movie or cartoon. Check the latest collection on their website.

Customized Hearing Aid

Such customizable hearing aid is printed using resin 3D printers. An audiologist scans the patient’s ear canal and then 3D prints a customized shell. Then electronics is inserted into the shell and this is it. Much more comfortable than before, custom-designed silicone aid with the skin color shade is ready to use.

3D Bioprinting

To a regular person, bioprinting is associated with the scene from a sci-fi movie when the character’s body parts get restored after some horrific injury. At some point, we may get there, but for now, it is possible to restore only certain tissues and there is very little success in 3D printing the whole organs. There is a whole page dedicated to 3D bioprinting on Wikipedia.

A bio 3D printer is equipped with syringes with biomaterial “inks” that extrude the needed amount layer by layer. Similarly, scientists successfully reproduce cow’s meat for consumption in a laboratory, as it is much greener for the planet, but this is the subject for another blog.

Tools, Instruments and Equipment

A significant role of 3D printing in healthcare is creating instruments. Clamps, forceps, hemostats can be 3D printed for the specific surgery in the precisely required amount and quickly. Another important point is that such items can be 3D printed in a specific size for the specific procedure/surgery. Such items are much cheaper to produce and are sterile.

Another note worth mentioning is that laboratories, generally, not only in medicine, benefit from using open-source equipment that can be put together with the help of a 3D printer. This saves a lot of money.

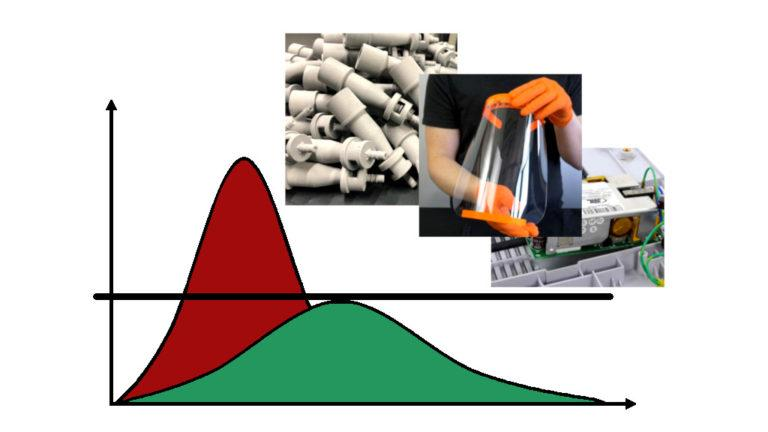

COVID – PPE and Ventilator Valves

These are the tools and equipment that can be 3D printed and used in healthcare. If the previous topic described the 3D prints that were not extremely necessary, then the following objects had to be 3D printed in the emergency situation.

What happened. Coronavirus affected all parts of our lives on a global scale. As the supply chain got disrupted, combined with a sharp increase in demand, hospitals got to the point when vital functional and protective equipment was not available in time. We witnessed how 3D printing manufacturers and community members come to the rescue.

PPE Shields Brackets – These are the vital PPE (Personal Protective Equipment) items that can be produced by 3D printing professionals and even enthusiasts.

Ventilator Valves – As the battle was raging and the oxygen was the most important element to save lives, hospitals had to find some of the equipment elements very quickly. The first real-case story, when 3D printing saved lives of many patients in intensive care, took place in Italy. The valves for respiratory ventilators were 3D printed by a local specialist at the hospital premises.

Conclusion

In the nineties, there were predictions that 3D printing would be widely used in dentistry and in the production of customized hearing aid. We can now see that such predictions have been fulfilled with even more practical uses. Please contact us or leave a comment below if we missed some of the applications of 3D printing in healthcare.

3D printed prosthetics for animals is one of the areas where 3D printing can be invaluable in producing customized ingenious contraptions. This 3D printing application has been pulling them back to their active lifestyles or being used as part of the treatment. We have been witnessing the continued adoption of this technology in various spheres of our lives, with some amazing success and even life-saving stories.