More and more, it seems that customization is driving the world. Creating products that fit the customer’s expectations is the need of the hour. 3D printing is a major factor in this, bringing customized solutions to an entirely new level. Just take a look at our articles on 3D printed fashion and 3D printed prosthetic arms, two examples of applications where 3D printing really shines.

When it comes to flexible and elastic applications, rubber is the ideal choice. But is rubber 3D printable? The short answer is no. Hence, we look for alternative materials that are similar to rubber but can be 3D printed.

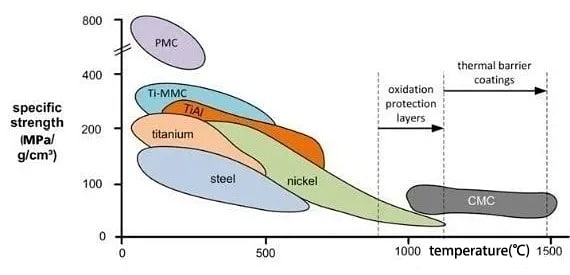

From the above chart, we see that elastomers and polymers fall into the category of flexible materials. Combining the advantages of thermoplastics and elastomers, we, therefore, arrive at a new 3D printable class of materials called thermoplastic elastomers (TPEs).

In this article, we’ll look at a few different types of TPE as well as another type of flexible filament called soft PLA. Hopefully, through reading about these different materials, you can get a better idea of which is best for your needs!

Overviews of TPEs

Thermoplastic elastomers (TPEs) are polymers that exhibit elasticity similar to that of a cross-linked rubber. The degree of elasticity in the material depends on the type of TPE and the chemical structure of the grade. In addition, this grade of elastomers come with the processing advantages of thermoplastics, which is good for 3D printing!

If you search for TPE filaments, you may become confused and a little annoyed at the options that appear. That’s because TPE is a wide category of materials, which includes several other types, such as TPU. We’ll see more of that very shortly.

It’s also important to note that not all varieties of flexible filament will be marketed as TPE, a subtype of TPE, or under any other recognizable material classification. Nevertheless, most will belong to one of the categories presented in this article.

Features of TPE

- Flexible and soft

- Excellent fatigue resistance

- Good electrical properties

- Excellent vibration damping

- High impact strength

- Excellent resistance to chemicals and weathering

- Good tear and abrasion resistance

- Recyclable

- Resistance to low and high temperatures (-30 to +140 °C)

- Good shock absorption

3D Printing Prerequisites

- Extruder temperature: 210–260 ºC (varies)

- Bed temperature: Unheated–110 ºC (varies)

- Print speed: 5–30 mm/s (keep it low, especially at the beginning)

- Bed adhesion: painter’s tape, glue stick, or hairspray recommended

- Extruder system: direct drive recommended

- Cooling fan: recommended

Challenges

- TPEs have the problem of being poorly handled by extruders owing to their softness.

- As TPEs are hygroscopic, they absorb moisture. As a result, prints will pop up and sizzle if filament isn’t stored properly.

- Remember that TPE is particularly sensitive to quick movements. Sometimes the filament might buckle when pushed through the extruder.

Classifications

TPE can be classified into six categories based on chemical structure. They’re also differentiated based on Shore hardness values. Here, we’ll discuss the different 3D printable grades of TPE:

- Thermoplastic polyurethane (TPU)

- Thermoplastic co-polyester (TPC)

- Thermoplastic polyamide (TPA)

Let’s look a little closer at each of these types in the following.

TPU

Thermoplastic polyurethane (TPU), is the most common type of TPE used in 3D printing. Compared to other flexible filaments, it exhibits greater rigidity, allowing it to extrude more easily. It also has decent strength and high durability.

Features

- High elastic range (typically ranges from 600–700%)

- Shore hardness between 60A and 55D

- Excellent printability

- Semi-transparent

- Better chemical resistance to oils and greases

- High abrasion resistance

3D Printing Prerequisites

- Extruder temperature: 210–230 ºC

- Bed temperature: Unheated–60 ºC

- Print speed: 5–30 mm/s

- Bed adhesion: Kapton’s or painter’s tape

- Extruder system: direct drive recommended

- Cooling fan: not recommended for the first layers

Challenges

- If the temperature is too high, stringing can occur.

- If the temperature is too low, layer adhesion will be poor.

- Resistance to UV light is poor.

Industrial Applications

- Shoe insoles

- Industrial belts

- Ski boots

TPC

Thermoplastic copolyester (TPC) are copolyether esters with alternating, random-length sequences of either long-chain or short-chain glycols. They have both hard and soft segments. Hard segments are typically short-chain ester units whereas soft segments are usually aliphatic polyethers and polyester glycols.

TPC is considered to be an engineering-grade material, which might explain why it doesn’t appear as much in the hobbyist 3D printing world.

Features

- Low density

- Elasticity in the range of 350–530%

- Shore hardness between 40 and 72D

- Good chemical resistance

- High strength

- Good thermal stability

- High-temperature resistance

3D Printing Prerequisites

- Extruder temperature: 220–260 ºC

- Bed temperature: 90–110 ºC

- Print speed: 5–30 mm/s

Challenges

- Comparatively, TPC presents less elongation at break. It can’t be used for highly flexible applications.

Industrial Applications

- Bellows

- Self-expandable polymer stents

TPA

Thermoplastic polyamide (TPA) is a chemical co-polymer of TPE and highly flexible nylon. The result is a combination of a smooth, lustrous texture, coming from nylon, and the flexibility of TPE.

Features

- High flexibility

- Elasticity in the range of 370–497%

- Shore hardness between 75 and 63A

- Exceptionally durable

- Good printability

- Good heat resistance

- Good layer adhesion

3D Printing Prerequisites

- Extruder temperature: 220–230 ºC

- Bed temperature: 30–60 ºC

- Print speed: 5–30 mm/s

- Bed adhesion: PVA-based recommended

- Extruder system: direct drive or Bowden

Challenges

- TPAs absorb moisture and, hence, should be stored in dry places.

- Warping is not uncommon.

Industrial Applications

- Winter sports, especially ski equipment

- Golf balls

- Medical products, such as catheters

Soft PLA

Soft PLA is a generic term applied to PLA blends that are made to be more flexible. In terms of its performance, some refer to it as “tough rubber”.

Compared to other flexible materials, it is known for its strength and durability. Printing it is similar to printing standard PLA, except that one should use a slower print speed and a higher bed temperature.

Features

- Biodegradable

- Shore hardness between 90 and 92A

- High strength

- Good durability

3D Printing Prerequisites

- Extruder temperature: 220–235 ºC

- Bed temperature: 100 ºC

- Print speed: 10–30 mm/s

- Extruder system: direct drive or Bowden

Challenges

- Due to its softness, there can be problems during loading the filament.

Industrial Applications

- Stoppers

- Springs

- Belts

Source: https://all3dp.com/2/flexible-3d-printing-filament-which-should-you-chose/