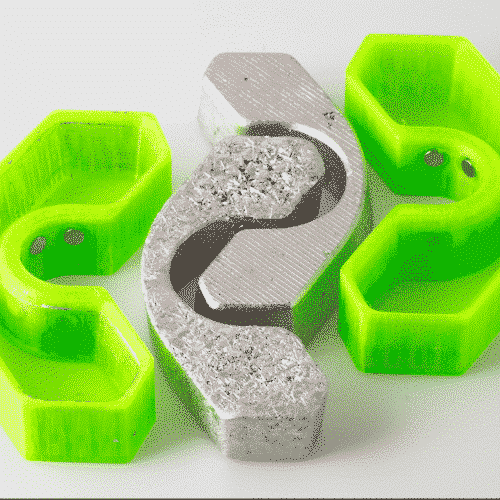

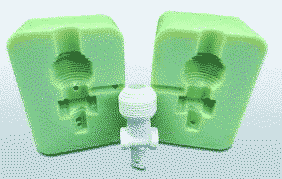

Silicone rubber is an elastomer (rubber-like material) composed of silicone. No matter what color it is, the quality is the same. It won’t have problems like deformation, shrinkage, high-temperature resistance.

A formed silicone rubber mold can be used repeatedly. The lifetime of the mold reaches two thousandths, and it’s mainly used for prototyping and low-volume product replications.

In the last article, we introduce the whole process of urethane casting. So, what are the common problems when making silicone rubber molds during urethane casting? We sum up 6 conditions through the failure we met.

1 The turnover rate of the mold is not ideal.

2 The mold loses tear-resistance and turns too soft to be pulled in daily use.

3 The mold is not resistant to acid, alkali, and aging.

Reasons

All of the above situations occur because too much silicone oil is added during the urethane casting process. Silicone oil destroys the molecular weight of the silicon rubber, so the mold appears to have fewer turnovers and be less durable.

In the process of making silicone molds, we recommend that customers should not add any silicone oil. If necessary, the amount of silicone oil should not exceed 5% to 10%. Too much silicone oil will damage the molecular weight of the silicon rubber, so the mold will lose tear resistance, acid & alkali resistance, and aging.

Here are two mistakes that frequently appear:

- Make a small and complicated mold with a hard silicon rubber.If you design a small product which has a complicated pattern and mold with hard silicone rubber, the mold turnovers will be less, because the silicone rubber will be brittle and easy to break when it is too hard.

- Conversely, if you make a large product and mold with soft silicone rubber, the result will also be unsatisfactory.Because silicone is too soft, its tensile strength and tear strength are both reduced, and the mold will be easily deformed, so the turnover is also reduced.

The qualities of different silicone rubbers are all good, you can judge it’s suitable or unsuitable. We just need to use suitable material based on the size and structure of the product.

4 The mold is burning, HELP!

It occurs from time to time because unsaturated resin products will generate a large amount of heat after they are added with peroxide curing agents. Sometimes the heat from the chemical reaction is too high and causes burning.

Generally, the curing time of the resin is 3 minutes. Therefore, it is necessary to release the mold as soon as possible after 3 minutes to prevent the silicone rubber mold from burning.

5 The exterior of the mold is dry but the interior is still wet.

The material used for molding is condensation cure silicon rubber. It’s solidified when absorbing the water in the air. During the process of molding, the water is evaporated.

This failure happens when you forgot adding the proper amount of water. In other words, it occurs when the moisture is not controlled or it has exceeded the storage period.

Solution: Add 0.05% water and stir the material evenly, this problem can be resolved.

6 Traces, streaks, and unevenness appear on the mold surface

That’s because the pattern to be copied is not sanded or polished. When the pattern itself is actually not smooth or perfect, the copied mold will also have traces, streaks on the surface. As a result, the products made from the mold will not be beautiful or smooth enough.

Another reason is that the mold release agent is not evenly applied. You need to check which is the corresponding reason in your case.